Heating towel wall hanging support based on graphene heating film and manufacturing method

A graphene and towel technology, applied in the field of towel racks, can solve the problems of poor ventilation and lighting effects in the bathroom, high rate of towel use, and poor drying effect, achieving fast drying speed, uniform heating, and reduced dust deposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

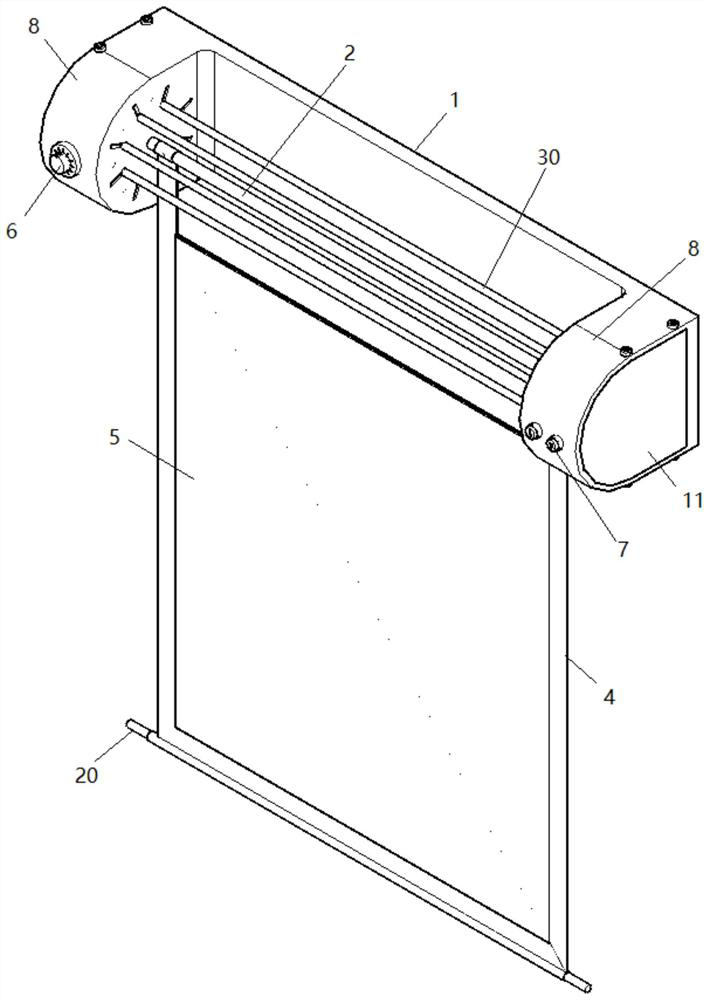

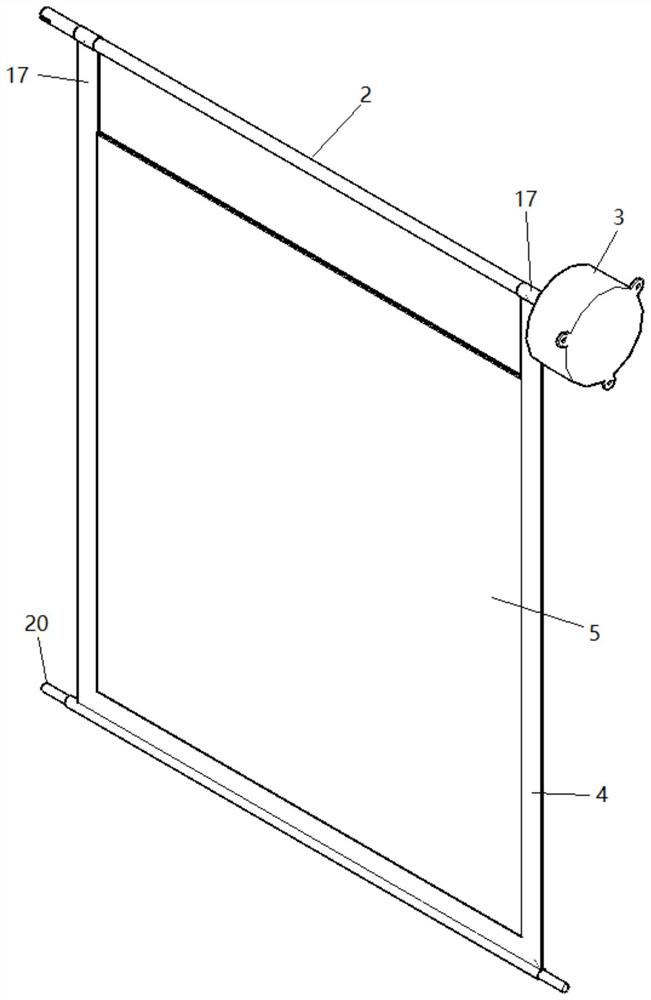

[0038] like Figure 1 to Figure 6 The first embodiment shown, a heating towel wall hanging bracket based on graphene heating film, comprising: a mounting plate 1, a towel shaft 2, a motor 3, a flexible and insulating base cloth 4, a flexible graphene heating film 5. Timing switch 6, up and down button switch 7.

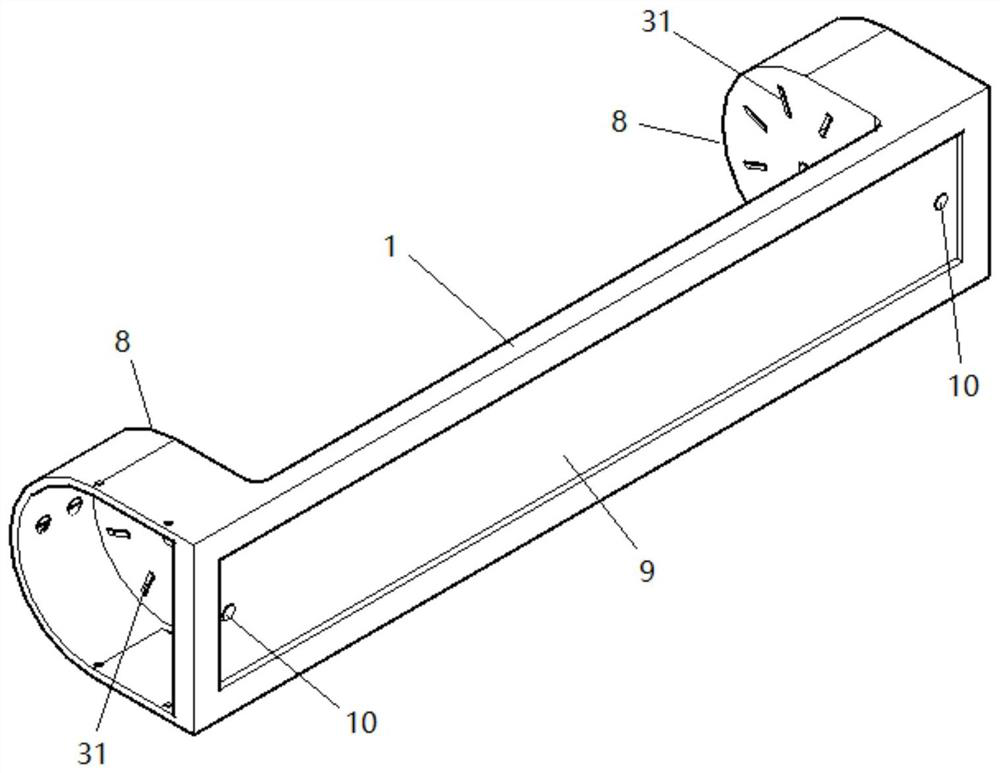

[0039] The left and right ends of the mounting plate 1 are respectively provided with mounting boxes 8 that protrude forward perpendicular to the mounting plate. The rear of the mounting plate 1 is provided with a rectangular accommodating groove 9. An end plate 11 is installed on the outside of the installation box 8 through the wire hole 10 .

[0040] The towel rotating shaft 2 is rotatably installed between the two installation boxes 8. The towel rotating shaft 2 is provided with two circles of limiting grooves 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com