Preparation method of submicron carboxyl functionalized polystyrene microspheres

A polystyrene microsphere and carboxyl functionalization technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of unsuitable ideal template raw materials and small particle size of polystyrene microspheres, and achieve high sphericity, Synthetic conditions are mild, the operation is simple and easy to repeat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of submicron carboxyl functionalized polystyrene microspheres, comprising the following steps:

[0036] (1) 20g of styrene was added to the four-hole glass kettle, and nitrogen was bubbled for 10min under the standing state;

[0037] (2) in step (1), add 200g deionized water, and turn on stirring, continue to feed nitrogen 30min, obtain the styrene solution that concentration is 0.96mol / L;

[0038] (3) add 1.20g methacrylic acid to step (2), then add 0.30g sodium dodecyl sulfonate and 0.03g n-butanol, stir until dissolved, and raise the reaction temperature to 50 ° C;

[0039] (4) adding 0.20g potassium persulfate and 0.2g polyvinyl alcohol to step (3), and making the reaction solution react at 75°C for 5h;

[0040] (5) The emulsion in step (4) was centrifuged and washed three times with ethanol, and then dried at 50° C. to obtain submicron carboxyl-functionalized polystyrene spheres.

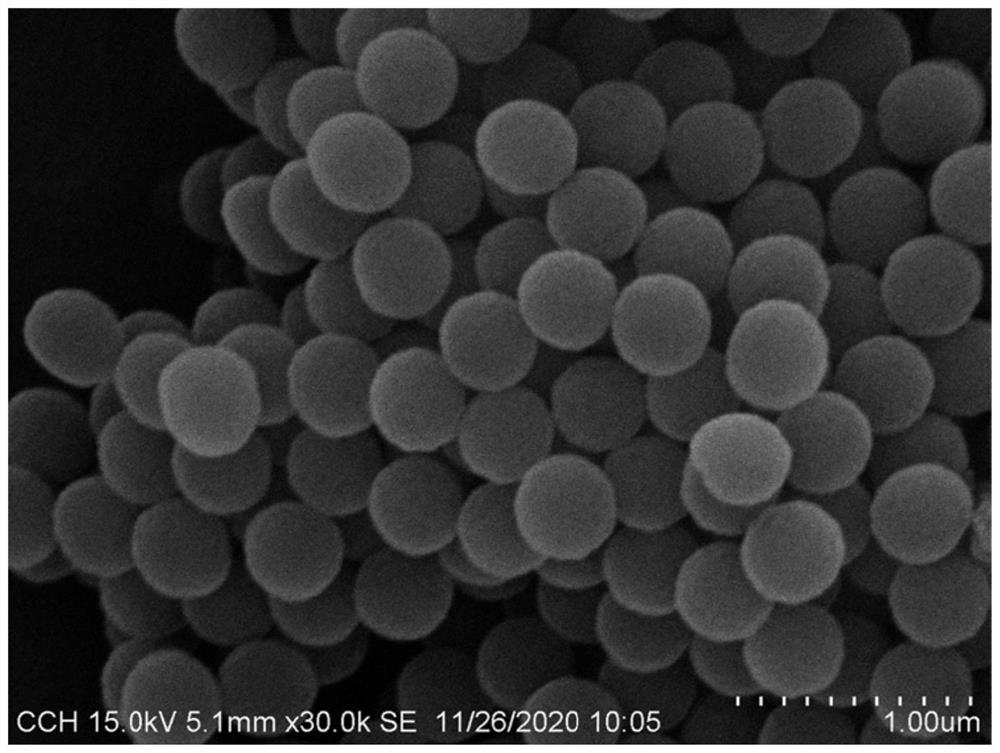

[0041] see figure 1 , 1# submicron carboxyl functionalized p...

Embodiment 2

[0043] A preparation method of submicron carboxyl functionalized polystyrene microspheres, comprising the following steps:

[0044] (1) 20g of styrene was added to the four-hole glass kettle, and nitrogen was bubbled for 10min under the standing state;

[0045] (2) in step (1), add 200g deionized water, and turn on stirring, continue to feed nitrogen 30min, obtain the styrene solution that concentration is 0.96mol / L;

[0046] (3) add 1.20g methacrylic acid to step (2), then add 0.30g sodium dodecyl sulfonate and 0.03g n-butanol, stir until dissolved, and raise the reaction temperature to 50 ° C;

[0047] (4) adding 0.30g potassium persulfate and 0.2g polyvinyl alcohol to step (3), and making the reaction solution react at 75°C for 5h;

[0048] (5) The emulsion in step (4) was centrifuged and washed three times with ethanol, and then dried at 50° C. to obtain submicron carboxyl-functionalized polystyrene spheres.

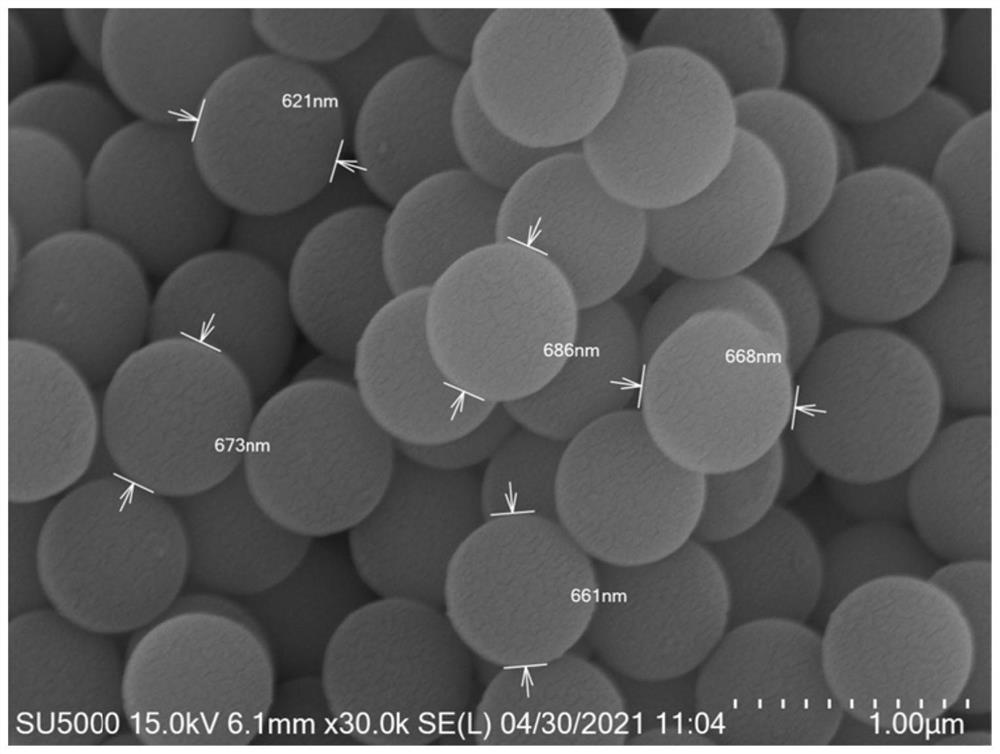

[0049] see figure 2 , 2# submicron carboxyl-functionalized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com