Polyurethane urea-rubber composite grouting material for inhibiting/breaking ice on grooved pavement and preparation method of polyurethane urea-rubber composite grouting material

A polyurethane urea and grouting material technology, applied in the field of pavement grouting materials, can solve the problems of lack of hydrophobicity and ice suppression, poor interfacial bonding performance, poor surface wear resistance, etc., which is beneficial to social promotion and mass production, and has low cost. , Improve the effect of anti-skid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

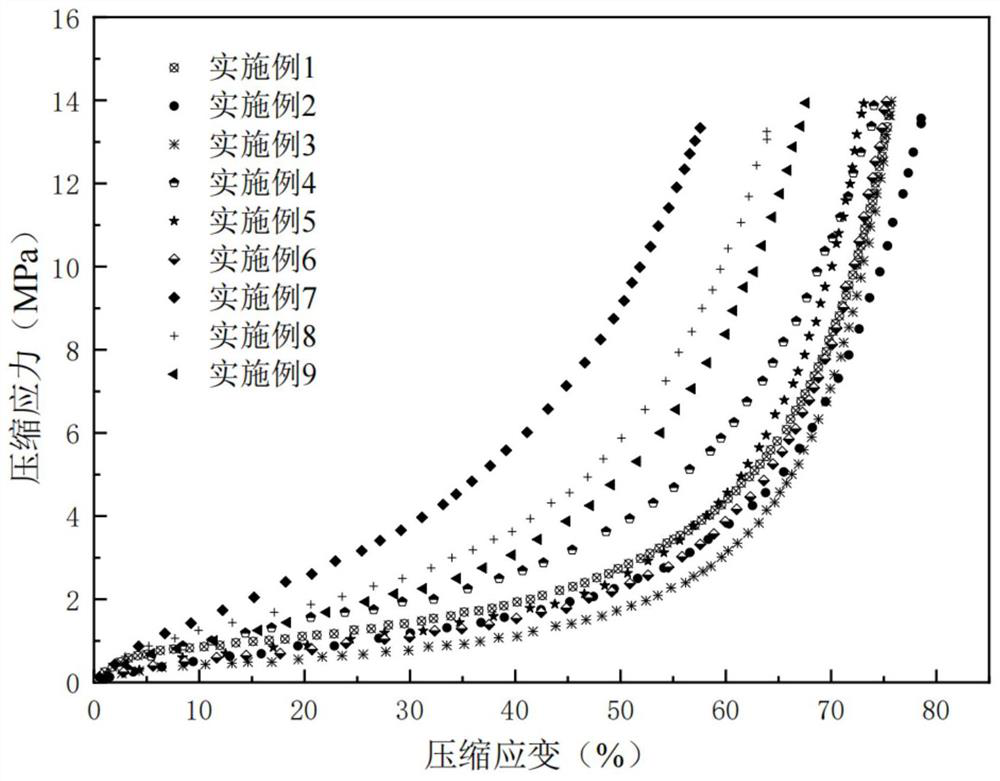

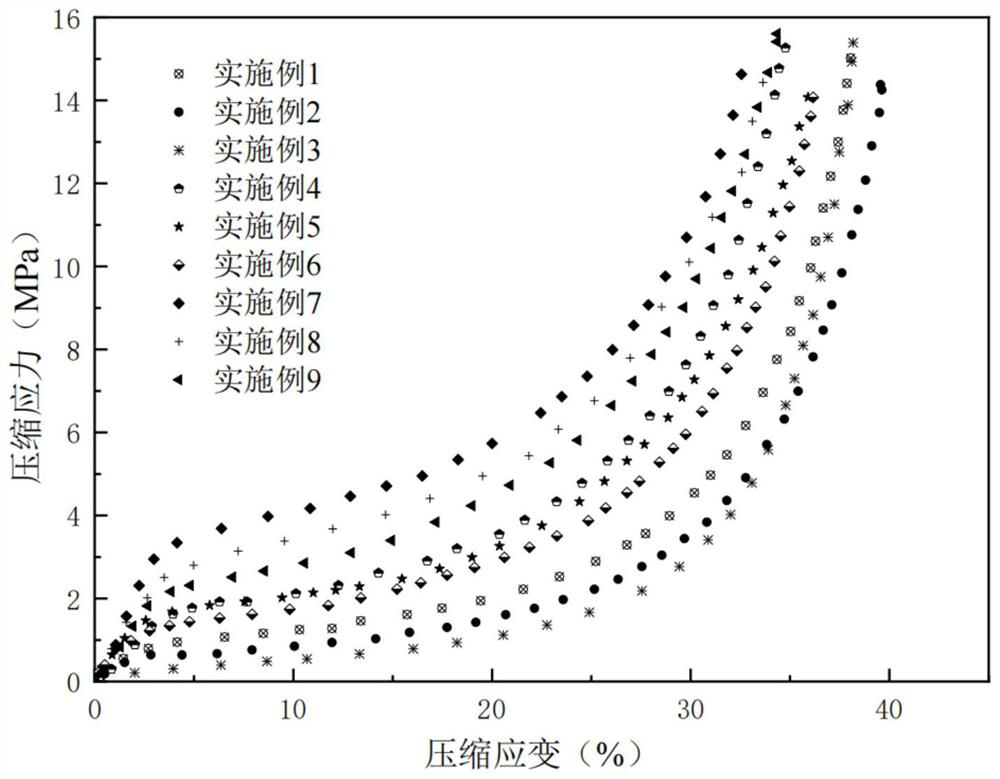

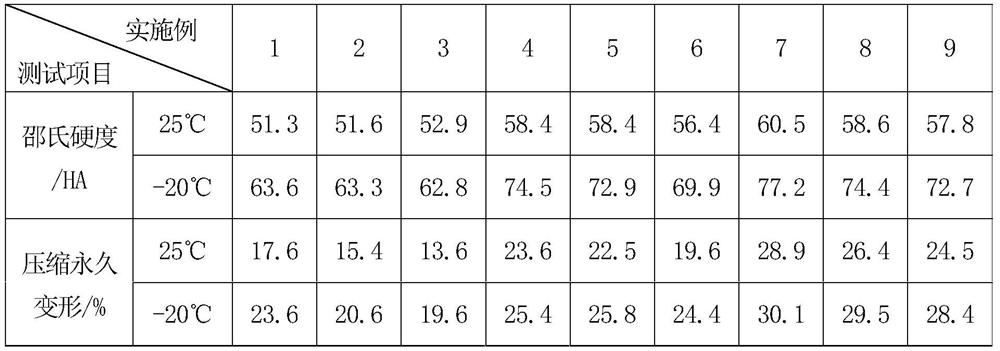

Embodiment 1

[0023] The polyurethaneurea-rubber composite grouting material in this example includes, in parts by mass, 41 parts of polyurethane A component, 205 parts of polyurethane B component, 52 parts of polyurea A component, 52 parts of polyurea R component, ethyl acetate 17.5 parts of esters, 1 part of dibutyltin dilaurate, and 150 parts of rubber particles with a particle size of 0.6 mm.

[0024] The preparation method of the polyurethaneurea-rubber composite grouting material in this embodiment is as follows: firstly mixing the polyurethane A component and the polyurethane B component, mixing the polyurea A component and the polyurea R component; then adding the obtained polyurea into the polyurethane , then add ethyl acetate and dibutyltin dilaurate, and stir at 25 ° C for 3 minutes until the cementitious material is stirred evenly, and no layering and segregation occurs; then add rubber particles with a particle size of 0.6 mm in 4 times and stir. Until the rubber particles are ...

Embodiment 2

[0026] The polyurethaneurea-rubber composite grouting material in this example includes 233 parts by mass of rubber particles with a particle size of 0.6 mm, and the mass parts of the other components and the preparation method of the composite grouting material are the same as those in Example 1.

Embodiment 3

[0028] The polyurethaneurea-rubber composite grouting material in this example includes 350 parts by mass of rubber particles with a particle size of 0.6 mm, and the mass parts of the other components and the preparation method of the composite grouting material are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com