Digital jet printing ink

A jet printing and digital technology, applied in the field of digital jet printing ink, can solve the problem of difficult control of functions, and achieve the effect that is conducive to the formation and permeability of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

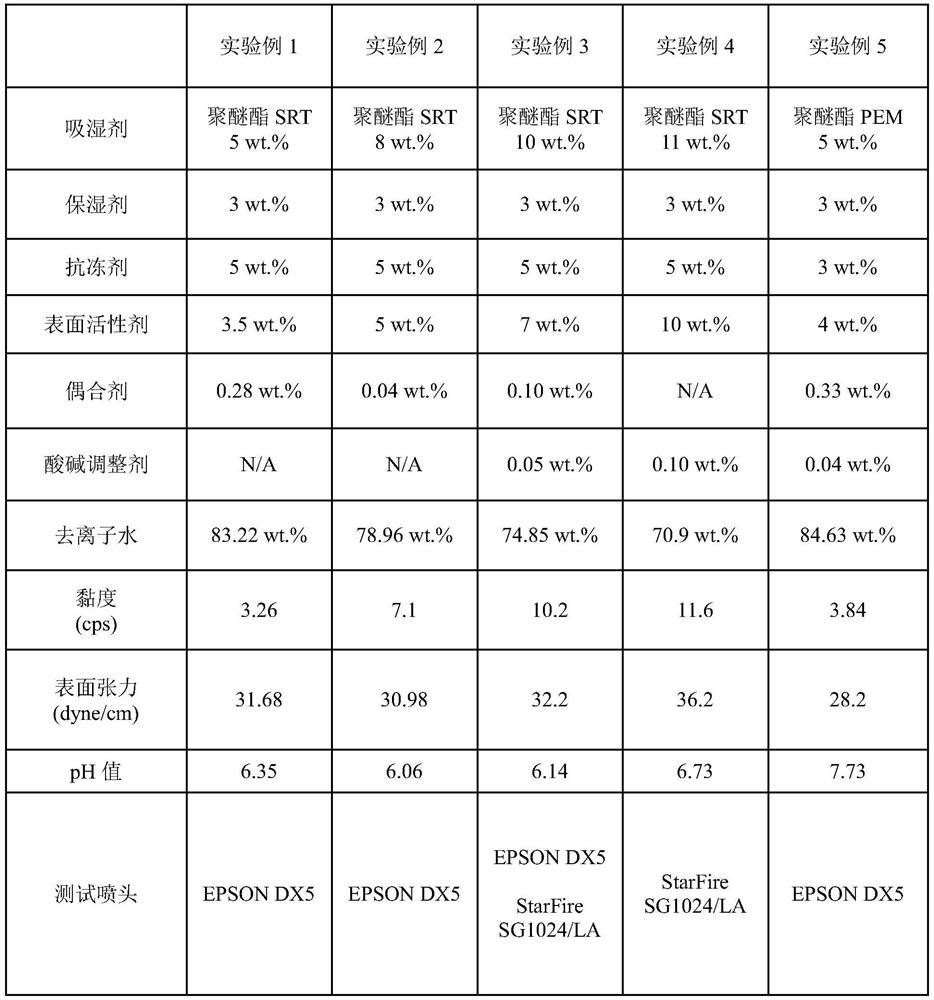

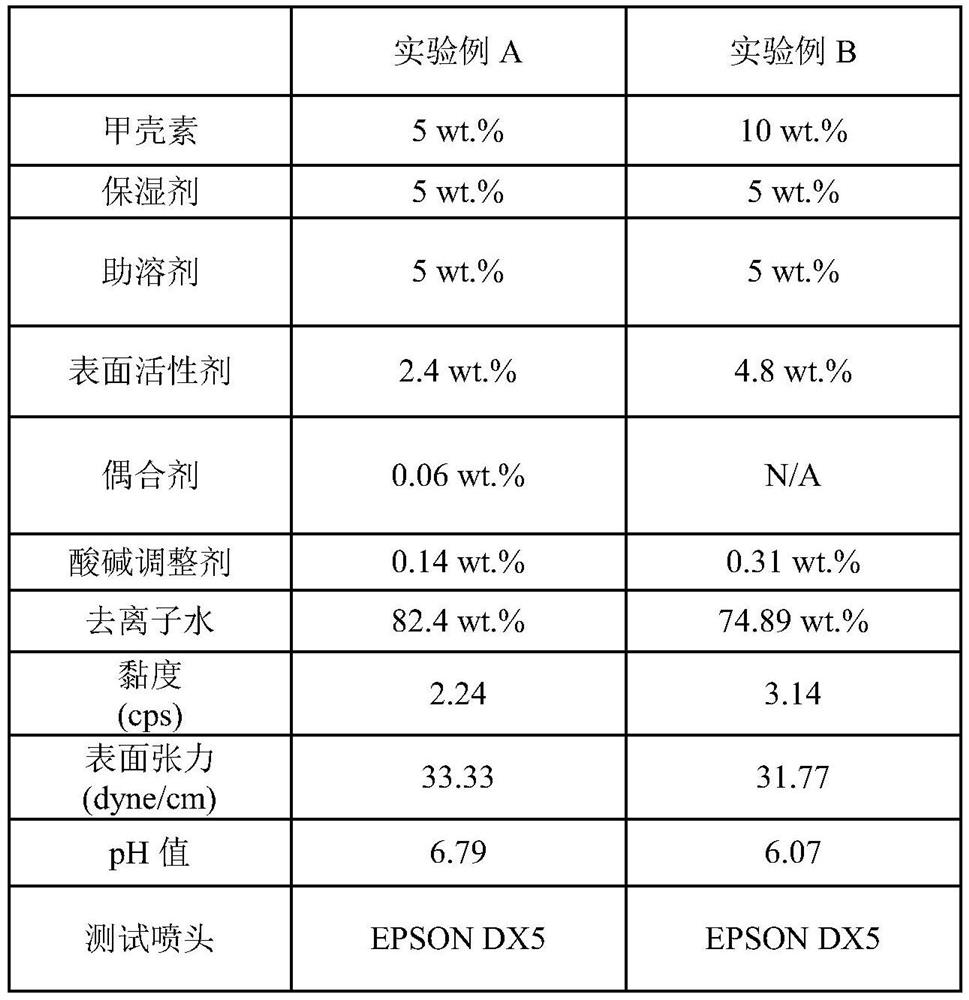

Examples

Embodiment Construction

[0021] The digital jet printing ink of the present invention can make the fabric have overall or partial functionality through digital precision jet printing, so it can be applied to clothing, home accessories, etc., such as sportswear, yoga clothes, vest underwear, tablecloths, bedding sets, etc. . In addition, since the digital ink jet printing ink of the present invention is formed on the fabric by means of digital precision jet printing, compared with the traditional impregnation pressure suction or coating method, the dosage used and the processing energy requirement can be saved by about one-third Second, it can precisely control the functionality of the ink. Furthermore, since the digital ink jet printing ink of the present invention contains hygroscopic agent and / or chitin, the fabric can have moisture regulating ability and / or bacteriostatic ability.

[0022] The digital ink jet printing ink of the present invention will be described in detail below.

[0023] Digita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com