Protection method for corrosion prevention of precast pile joint

A technology of prefabricated piles and joints, used in protection devices, sheet pile walls, buildings, etc., can solve the problems of loss of anti-corrosion function, friction damage of surrounding soil, loss of durability, etc., to achieve clear principles, prevent post-construction risks, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for protecting the joints of prefabricated piles from corrosion, comprising the following steps:

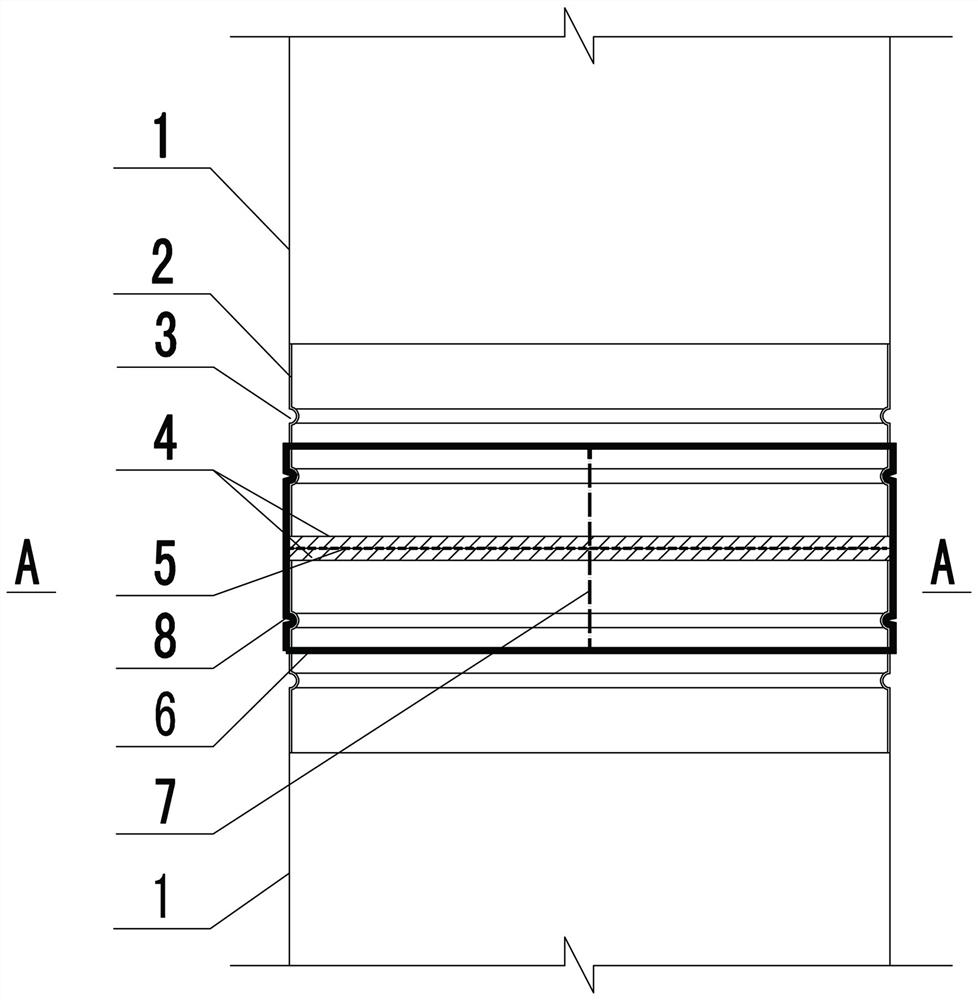

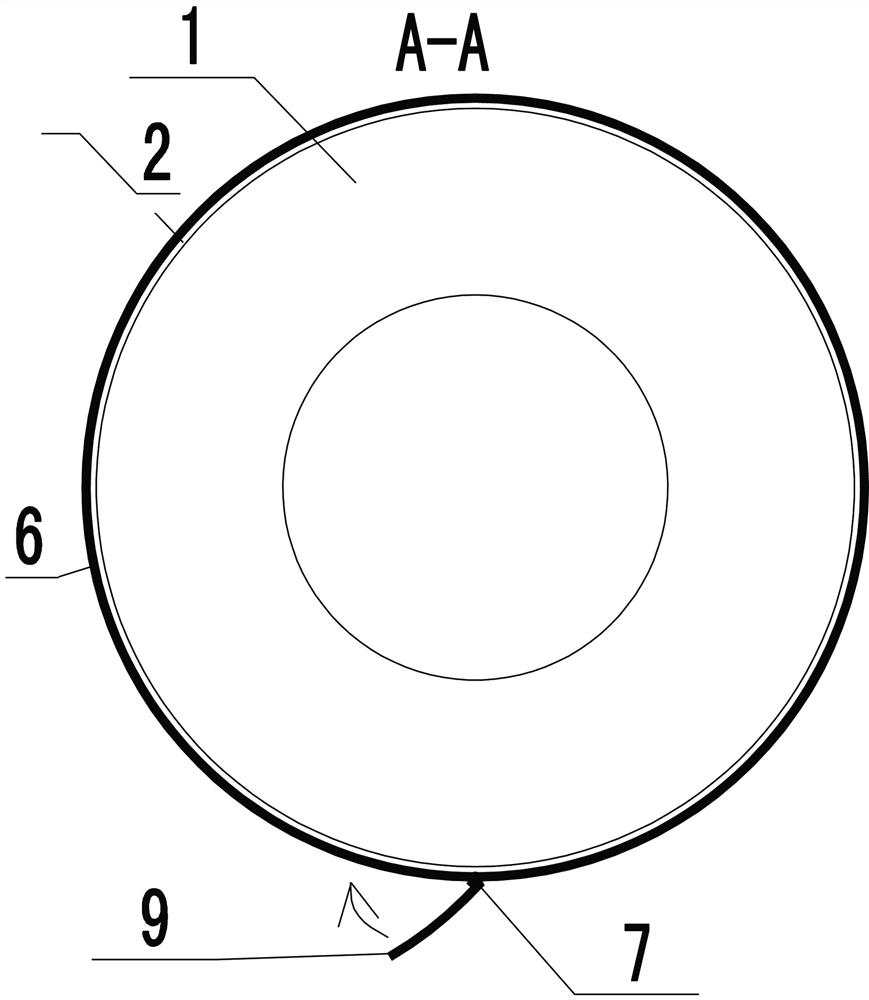

[0024] 1. According to the size of the prefabricated pile 1 in the actual project (it can be a round pipe pile or a square pile, or both can be hollow), prefabricated a sheet-shaped protective sleeve 6 of the corresponding size, of which the main size is at least one prefabricated pile hoop 2. Outer perimeter, location and size of prefabricated pile collar dents 3. In this embodiment, there are two circles of prefabricated pile hoop dents 3 at the joint of the prefabricated pile 1 .

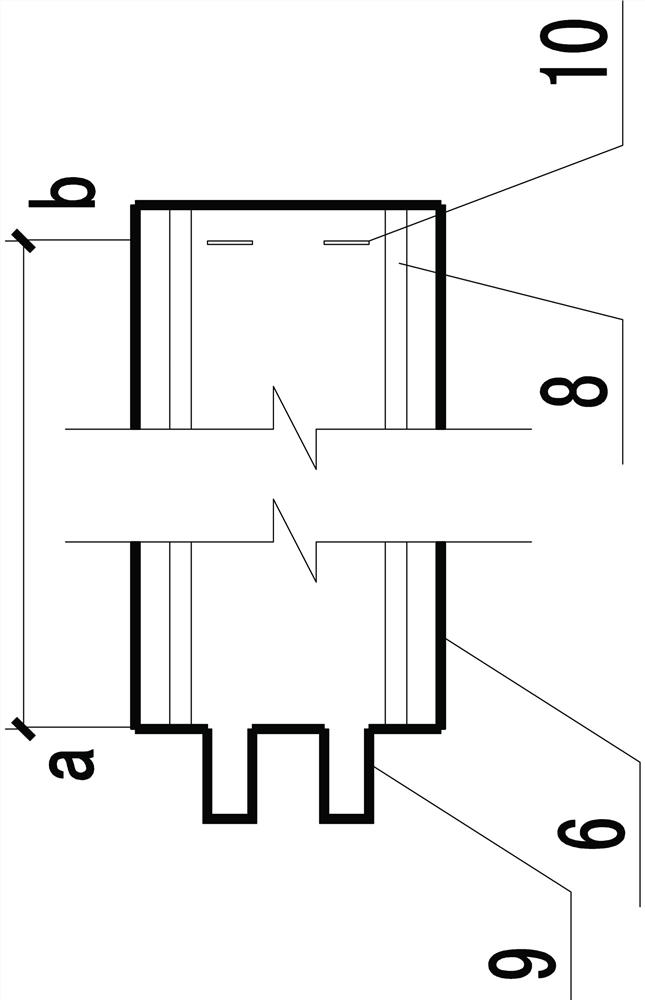

[0025] 2. The protective cover 6 can be made of steel, with a thickness of 1mm and a generally rectangular shape, such as image 3 The shown left and right length ab is the outer circumference of the prefabricated pile hoop 2, the width is generally 170mm (can be adjusted according to the actual situation), and at least two protective sleeve dents 8 are provided (the size is consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com