Hydraulic station device with temperature monitoring and alarming system

An alarm system and hydraulic station technology, which is applied in the field of hydraulic station equipment, can solve the problems of hydraulic component damage life, no monitoring and early warning mechanism, and hydraulic oil quality degradation, so as to ensure the use effect, facilitate subsequent normal use, and compact parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

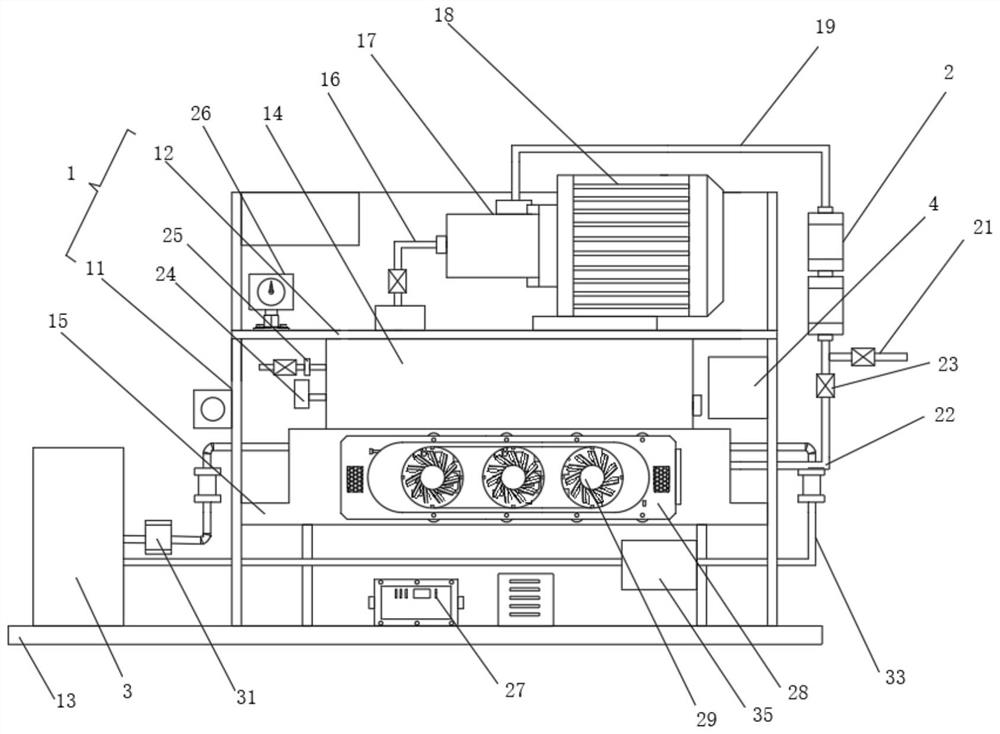

[0020] see Figure 1-4 , the present invention provides a technical solution: a hydraulic station device with a temperature monitoring and alarm system, including a support mechanism 1, the support mechanism 1 includes a vertical plate 11, a support plate 12 and a bottom plate 13, and the support mechanism 1 is sequentially provided with an oil tank 14. Filtration mechanism 2, cooling mechanism, monitoring mechanism and control mechanism;

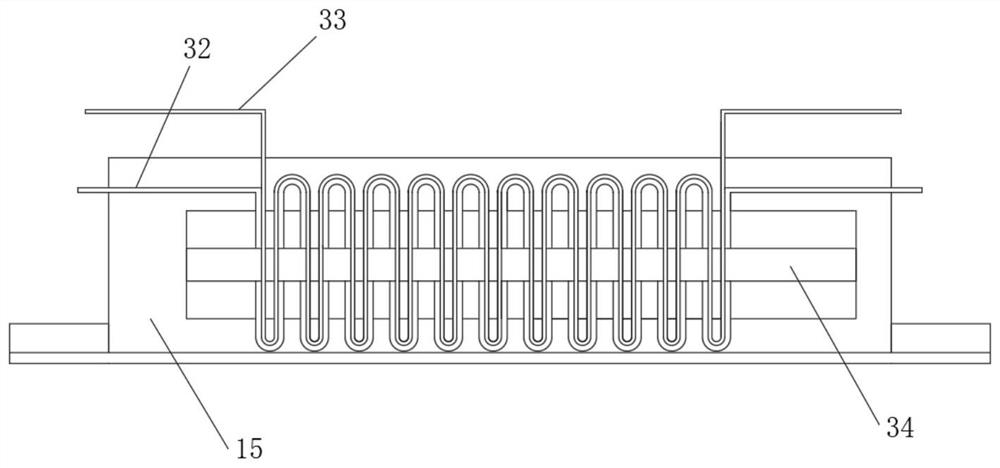

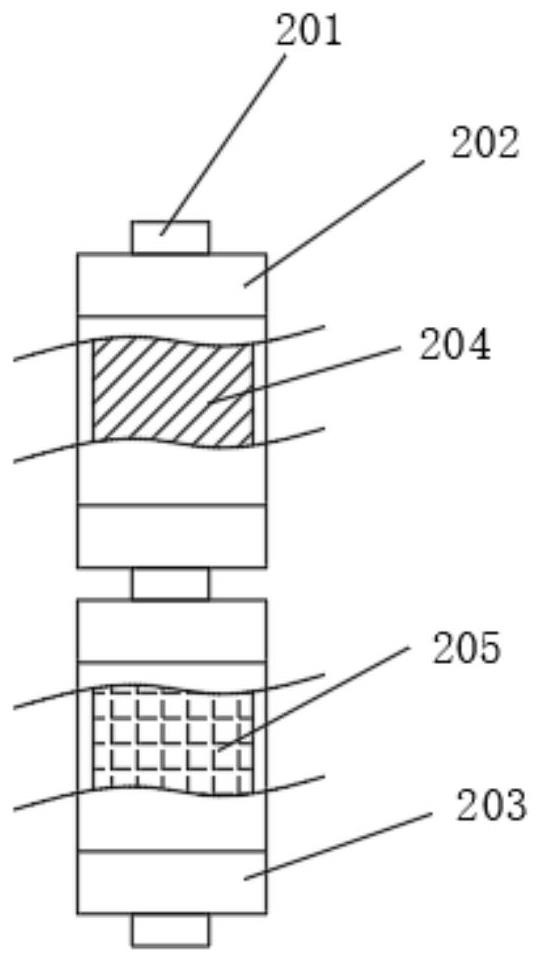

[0021] The oil tank 14 is installed in the bracket 15. The oil outlet of the oil tank 14 is connected to the oil pump 17 through the first oil outlet pipe 16. The side of the oil pump 17 is provided with a motor 18 for driving the oil pump 17, and the other end of the oil pump 17 is connected to the filter mechanism through the second oil outlet pipe 19. 2. The other end of the filter mechanism 2 is connected to the oil discharge pipe 21 and the oil return pipe 22 through a tee pipe, and the oil return pipe 22 is connected to the oil return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com