Three-chamber rare earth recovery waste heat furnace

A waste heat furnace and chamber technology, applied in the field of boilers, can solve the problems of ineffective recycling of flue gas, short flue gas circulation, environmental pollution, etc., so as to reduce the energy cost of enterprises and the emission of air pollutants, and facilitate centralized recovery. The effect of utilizing and improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

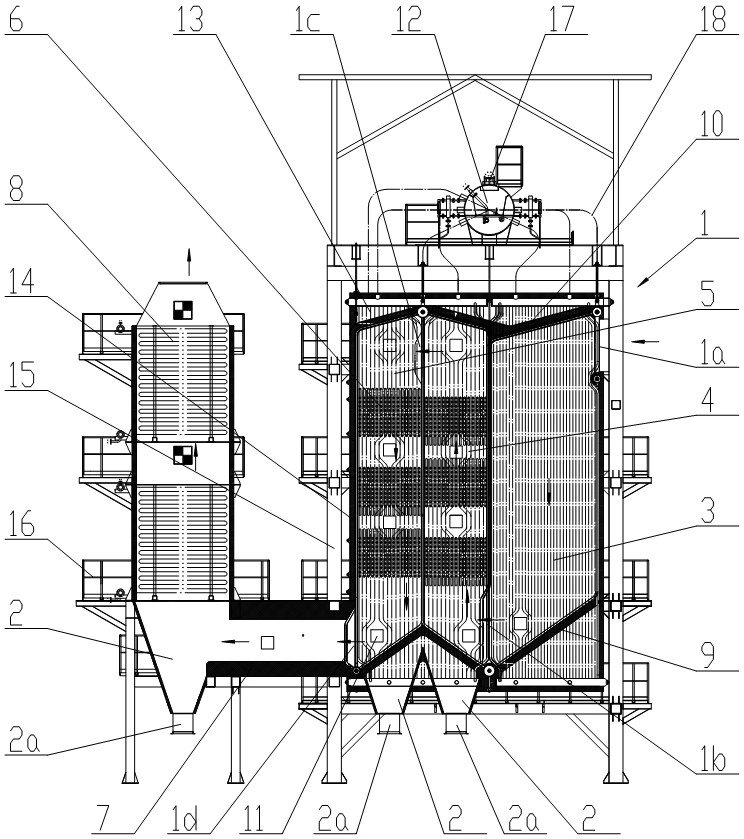

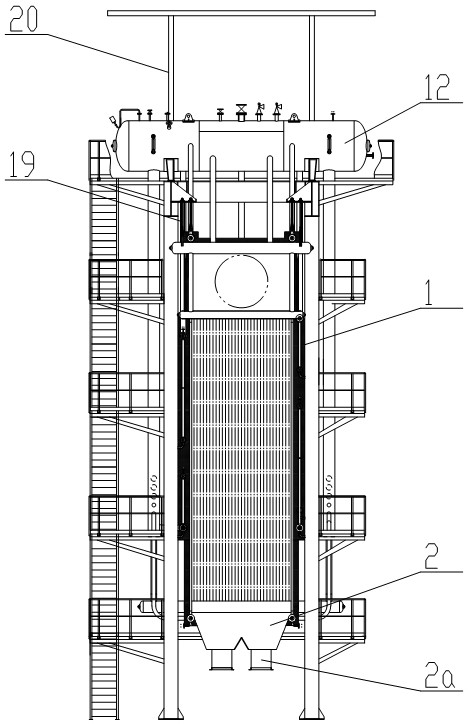

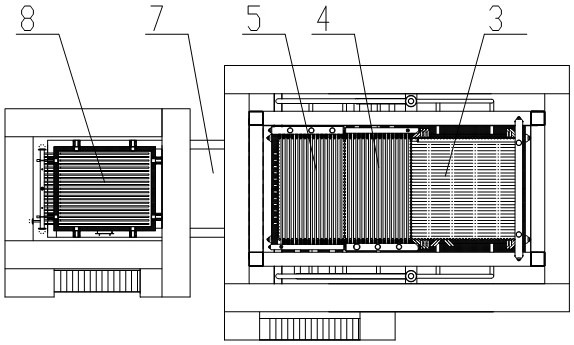

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0026] like Figure 1-3 As shown, a three-chamber rare earth recovery waste heat furnace includes a boiler body, the boiler body includes a flue gas chamber 1 and an ash hopper 2 arranged under the The first chamber 3 , the second chamber 4 and the third chamber 5 , the first chamber 3 , the second chamber 4 and the third chamber 5 are all full-membrane wall structures. A flue gas inlet 1a is arranged on one side of the top, a lower connecting port 1b is arranged at the bottom of the first chamber 3 and the second chamber 4 to communicate the two, and is arranged on the top of the second chamber 4 and the third chamber 5 There is an upper connection port 1c connecting the two, and a flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com