High-precision plate rolling machine based on machine vision

A machine vision, high-precision technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inconvenient monitoring of curled sheets and waste of staff time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

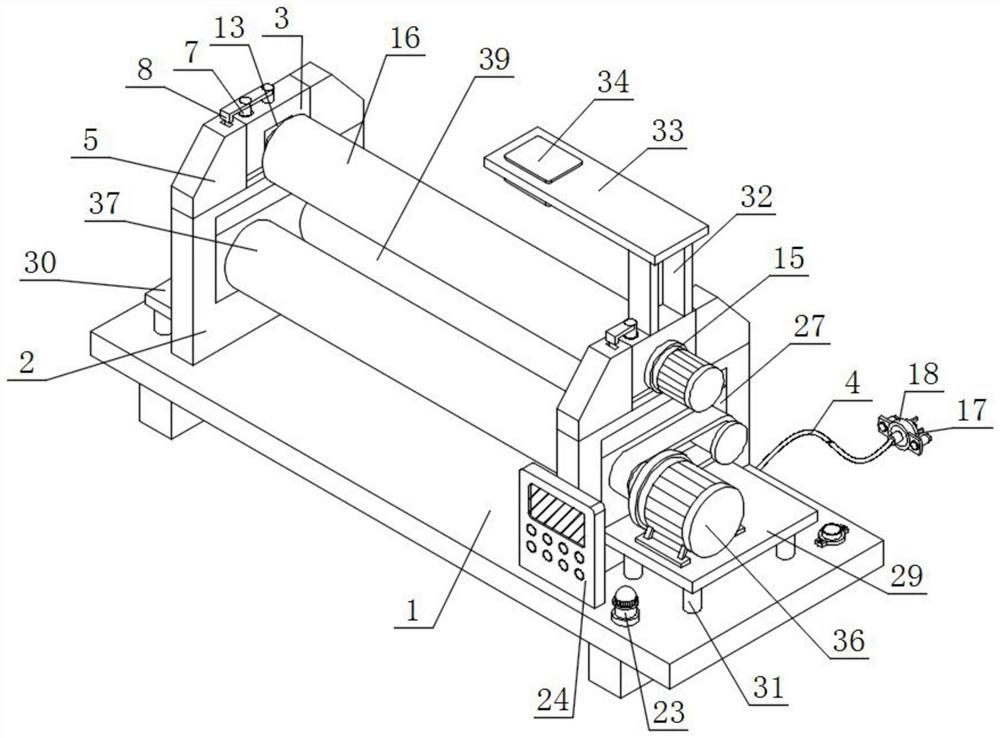

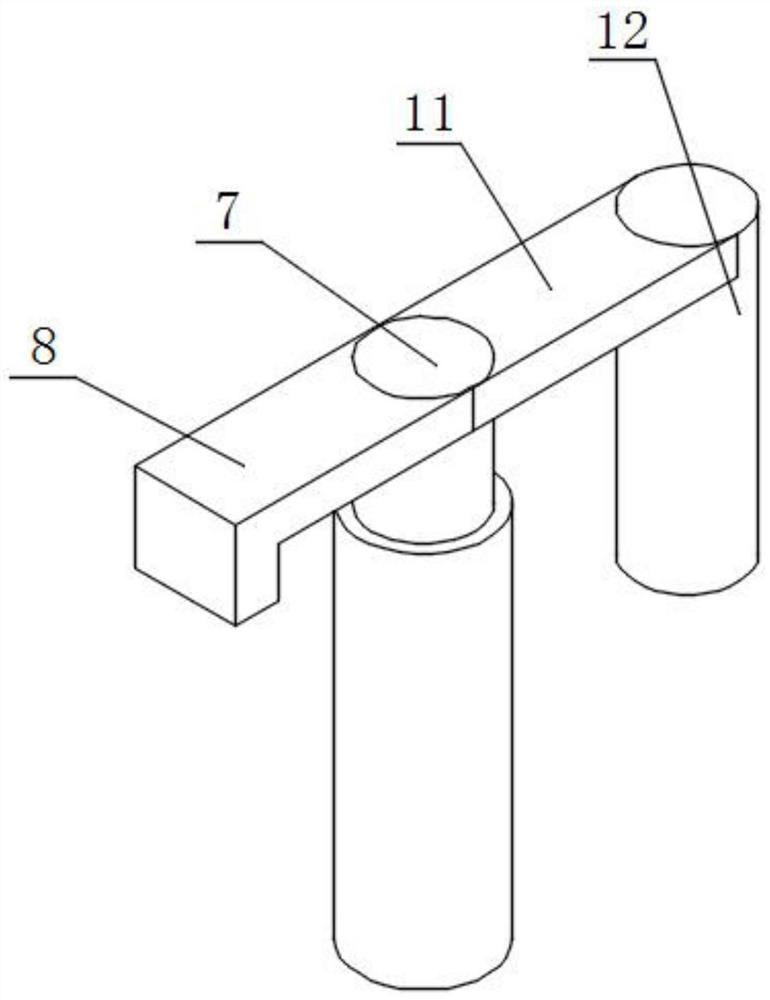

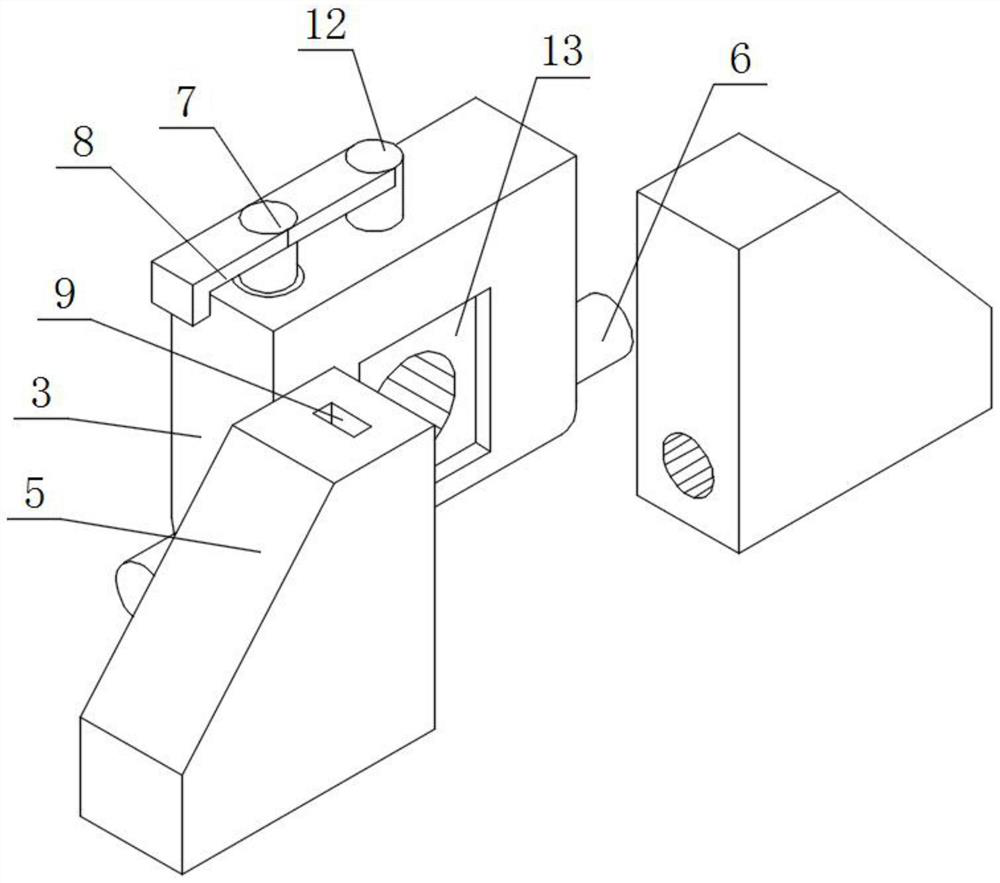

[0042] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a high-precision plate rolling machine based on machine vision includes a base 1, a vertical plate 2, a movable block 3 and a connecting line 4. Two sets of vertical plates 2 arranged side by side are installed on the top of the base 1, and two sets of vertical plates are installed. A movable block 3 is installed on the top of 2;

[0043] Specifically, the base 1 is used to integrate the components installed on its top, and to avoid the bottom of such components directly contacting the ground to be placed, so as to reduce wear and tear. The three groups of rotating rollers installed have enough space for movement, and the two groups of triangular blocks 5 of the movable block 3 are in a non-fixed fit state. For fixed-point rotation, change the placement state of the movable block 3.

[0044] A connecting line 4 is installed on the back of the base 1;

[0045] Specifically, the connecting wire 4 is used a...

Embodiment 2

[0051] like figure 1 and Figure 5 As shown, a socket 17 is installed at the tail end of the connecting wire 4, a protection ring 18 is installed on the outer surface of the socket 17, an assembly plate 19 is installed on the outer walls of both sides of the protection ring 18, and the front surfaces of the two groups of assembly plates 19 are installed. Both are provided with threaded grooves 20, the inner walls of the two sets of threaded grooves 20 are equipped with collars 21, the inner walls of the two sets of collars 21 are equipped with miniature electric extension rods 22, and the top of the base 1 is equipped with a voice prompt 23 and a controller 24, and the voice prompter 23 and the controller 24 are electrically connected, a vibration sensor is installed on the top of the base 1, and the voice prompter 23 of the vibration sensor is electrically connected.

[0052] Specifically, after the socket 17 is connected to the power socket, the device can be powered on to ...

Embodiment 3

[0054] like figure 1 , Image 6 and Figure 8 As shown, one side outer wall of the two sets of vertical plates 2 is provided with a notch 25, the front wall and the rear wall of the notch 25 are provided with a fitting groove 26, and the inner wall of the two sets of notches 25 is installed with a comprehensive block 27, Long strips 28 are mounted on the front and back of the integrated block 27 , and the outer walls of the long strips 28 are in contact with the inner walls of the fitting grooves 26 .

[0055] Specifically, the height of the slot 25 is greater than the height of the integrated block 27, and the integrated block 27 can move up and down inside the slot 25 under the driving of external force to adjust the corresponding height position, and the long strip 28 can be non-fixedly attached to the The interior of the fitting groove 26 increases the connection between the integrated block 27 and the riser 2 .

[0056] A square plate 29 is installed on one outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com