Gear grinding machine and indexing compensation method for gear machining

A compensation method and gear grinding machine technology, applied in the indexing compensation of gear processing, gear grinding machine field, can solve the problems of deviation, time-consuming and laborious, affecting the accuracy of indexing error compensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0040] Without loss of generality, this paper takes the gear grinding machine for machining spiral bevel gears and the indexing compensation method for machining spiral bevel gears as examples. For other types of gears, the core scheme can also be used for reference. Specifically, it can be adjusted adaptively according to different types of gears, and will not be described one by one.

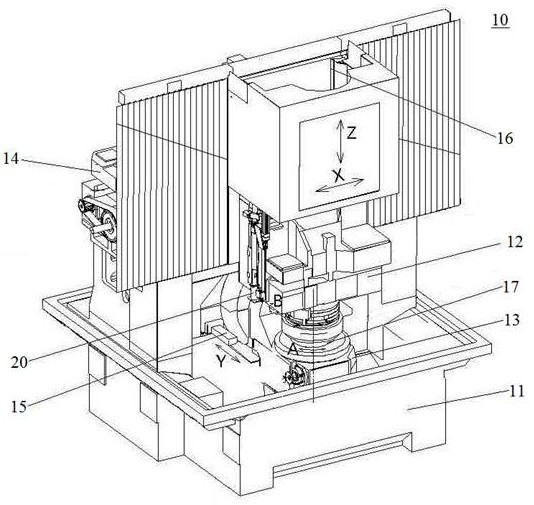

[0041] like figure 1 shown, figure 1 The gear grinding machine in the figure is of a vertical layout structure. The gear grinding machine 10 includes a bed 11, a workpiece box 13 mounted on the bed 11, a grinding wheel box 12, a rotary shaft box, an X-axis slide table 14, a Y-axis slide The axis slide table and the Z-axis guide rail 16, wherein the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com