Intelligent detection equipment using robot for production

An intelligent detection and robot technology, applied in the field of intelligent robots, can solve problems such as inconsistent blade gap angles, easy deformation of blades, and difficulty in maintaining rotational balance, so as to avoid inconsistent gap angles, improve welding quality, and avoid deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

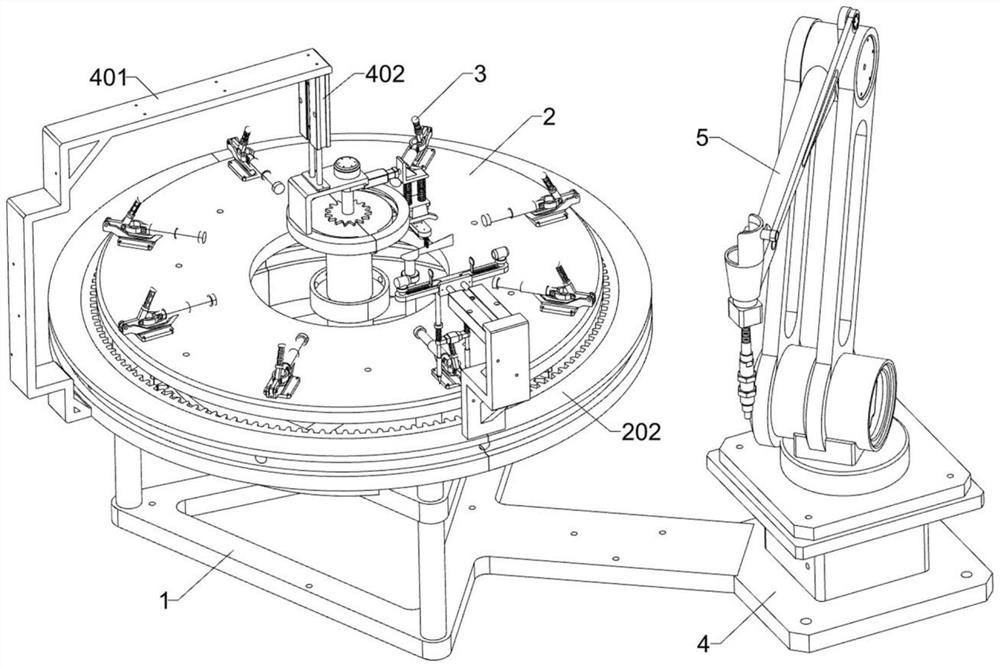

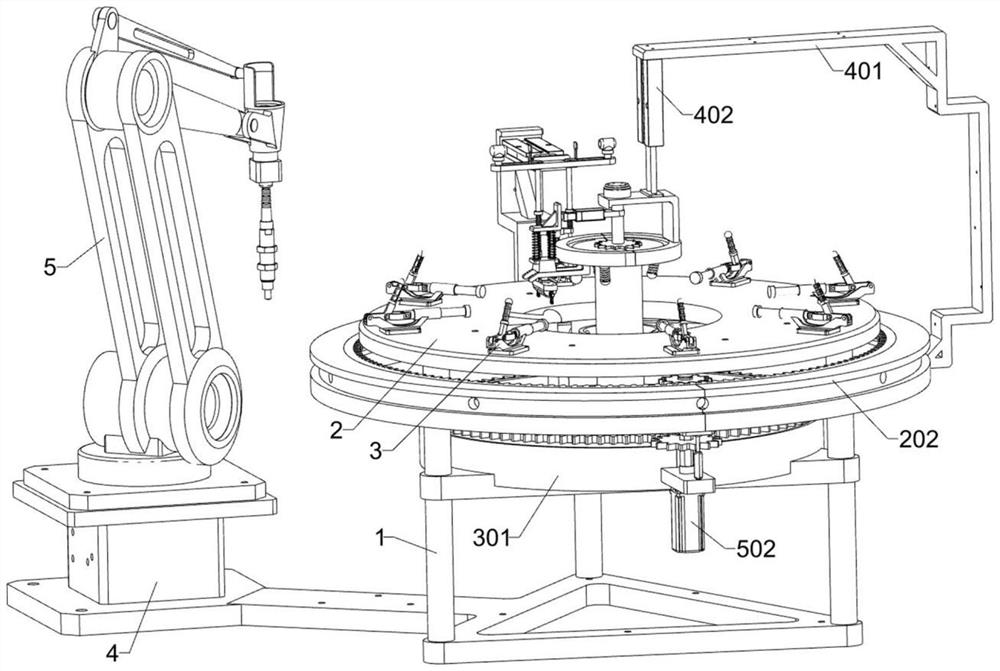

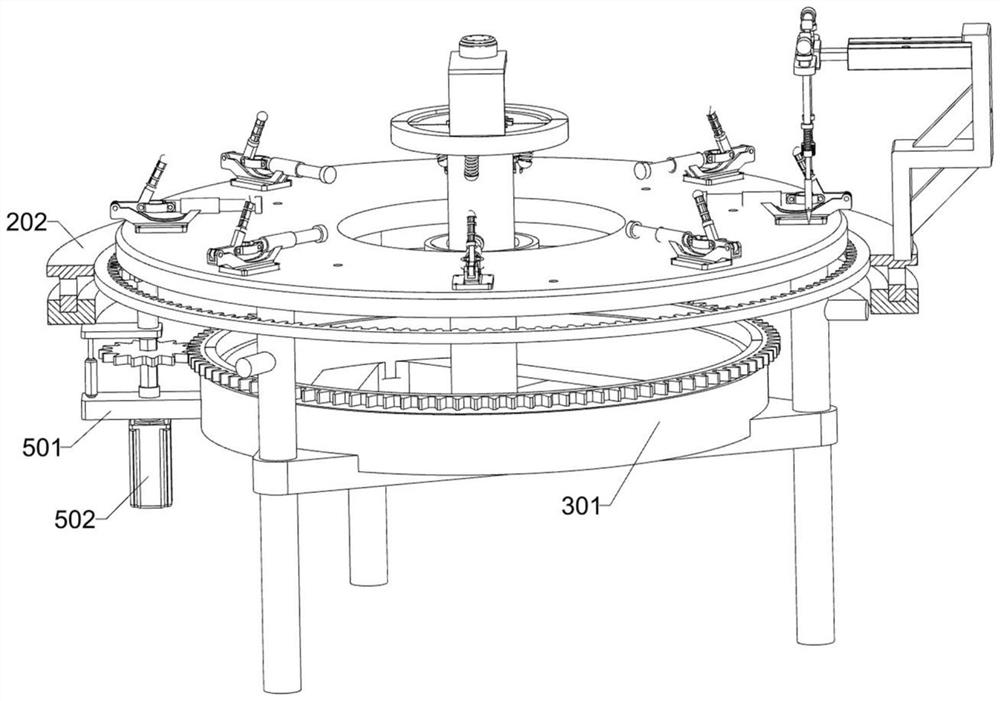

[0036] An intelligent inspection equipment produced by robots, according to Figure 1-2 As shown, it includes a bottom frame 1, a round table 2, a fixture 3, a base 4, a mechanical arm 5, a fixed rod 6 and a support ring 7; the round table 2 is welded on the upper end of the bottom frame 1; the circular equidistant bolts on the upper surface of the round table 2 are connected with A plurality of fixtures 3; a base 4 is welded on the right part of the base frame 1; a robotic arm 5 is bolted on the upper part of the base 4; a fixing rod 6 is welded on the upper part of the base frame 1; 7. The inner side is annularly provided with a plurality of bumps for limiting the position of the base 8 of the fan blade 9;

[0037] It also includes a transmission component, a laser ranging component, a top rod 211, a telescopic plate 212 and a second spring 213; the transmission component is connected with a laser ranging component; the laser ranging component is connected with two top rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com