Cargo grabbing device for industrial robot

A technology of industrial robots and grabbing devices, applied in the direction of conveyor objects, manipulators, manufacturing tools, etc., can solve problems such as falling goods, reduce the probability of falling, ensure installation stability, and improve clamping stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

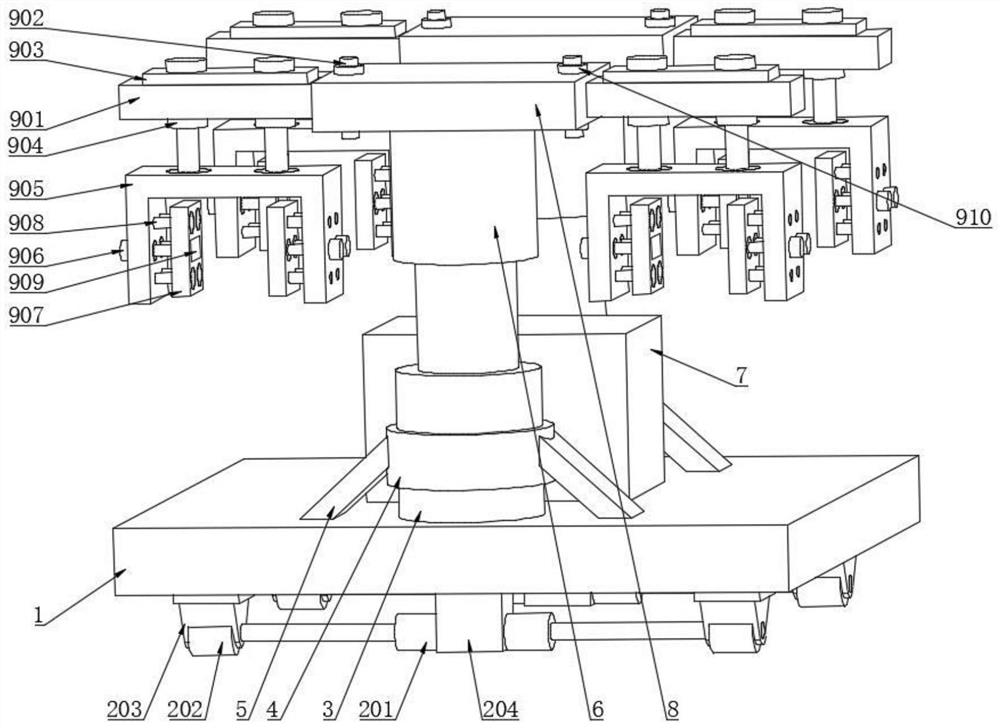

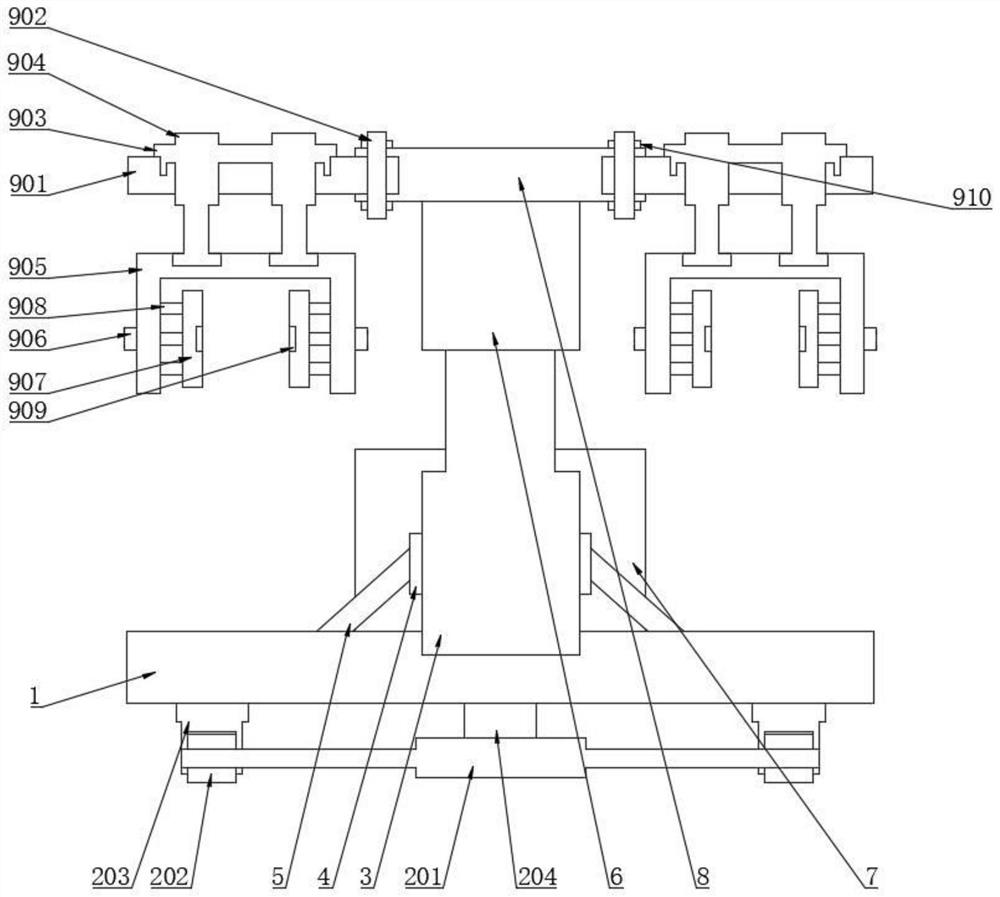

[0037] see Figure 1-5, a cargo grabbing device for industrial robots, including a pallet 1, which can ensure the working stability of the upper and lower parts under the action of the pallet 1, so as to ensure the actual use effect;

[0038] Also includes:

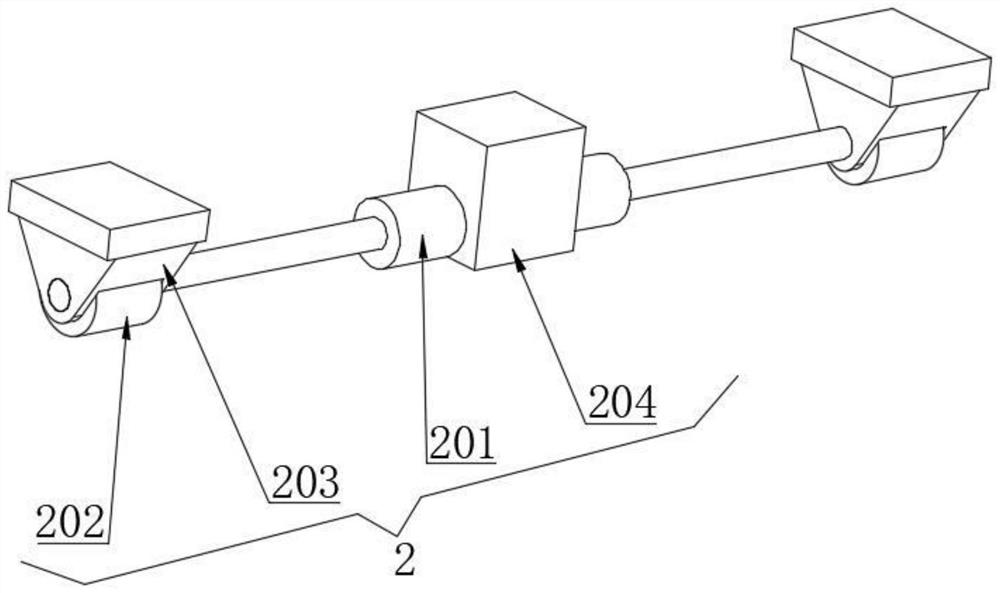

[0039] Two sets of symmetrically arranged moving mechanisms 2: each moving mechanism 2 includes a motor 201, a moving wheel 202 is sleeved on the circumferential surface of the motor shaft at both ends of the motor 201, and a protective frame 203 is provided outside the moving wheel 202; The start and stop of the motor 201 can be realized under the action of the motor 201, and the starter motor 201 can drive the motor shaft to make a circular motion, and can drive the moving wheel 202 to rotate under the action of the motor shaft, thereby realizing the moving purpose of the device.

[0040] Two symmetrically arranged electric push rods 3: the two electric push rods 3 are detachably installed on the upper end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com