Automatic production system for reinforced concrete prefabricated cover plate

A reinforced concrete and production system technology, applied in the direction of manufacturing tools, supply devices, grinding machines, etc., can solve the problems affecting production, falling on the conveyor belt, falling concrete blocks, etc., to achieve uniform weight and thickness, improve Improve production efficiency and prevent dust from scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

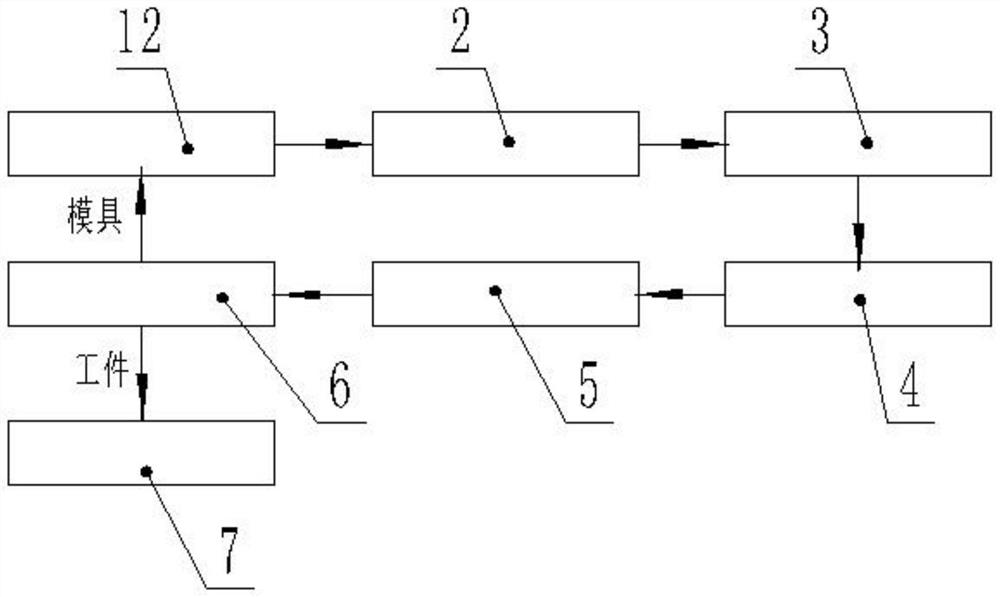

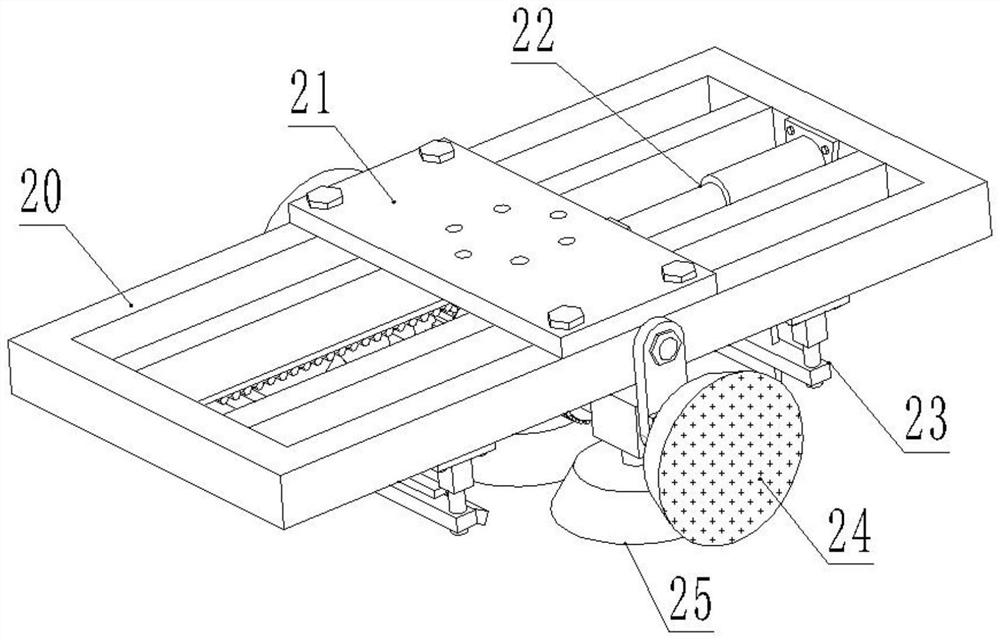

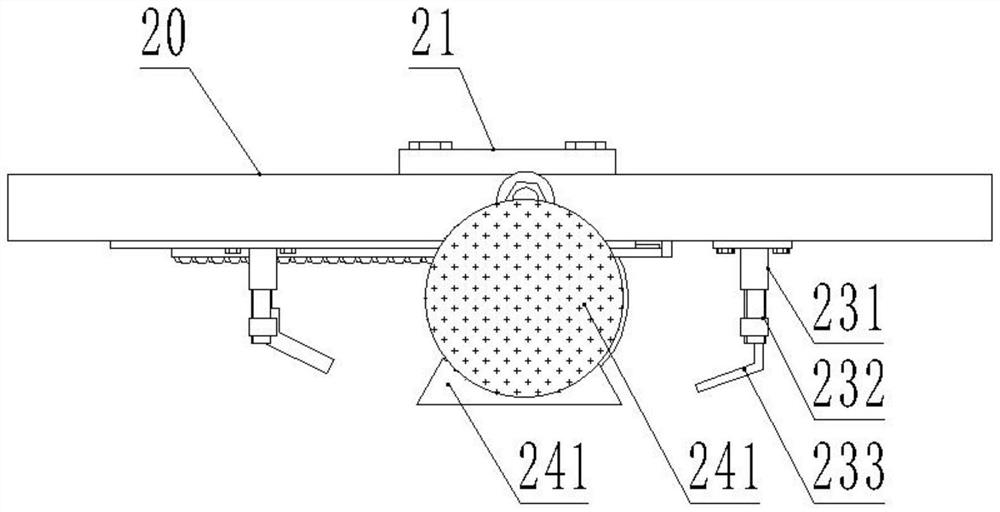

[0063] The invention discloses an automatic production system for reinforced concrete prefabricated cover plates, such as figure 1 As shown, it includes a mold cleaning device 12, a mold release agent automatic spraying device 2, a distribution equipment, a curing furnace 5, a mold release device 6, and an intelligent packaging device 7 arranged in sequence along the workpiece production process. A conveyor belt is arranged between the intelligent packaging devices 7, and a mother car for entering and leaving the kiln is arranged at the 5 place for curing the kiln. The inner wall of the mold is cleaned and dedusted by the mold cleaning device 12, and then the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com