Safe transportation cage for oxygen and acetylene

An oxygen acetylene and safety technology, applied in the field of oxygen acetylene bottle storage equipment, can solve the problems of potential safety hazards, difficulty in positioning and fixing bottles at different heights, etc., to ensure safety, prevent bottle dumping, and ensure the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

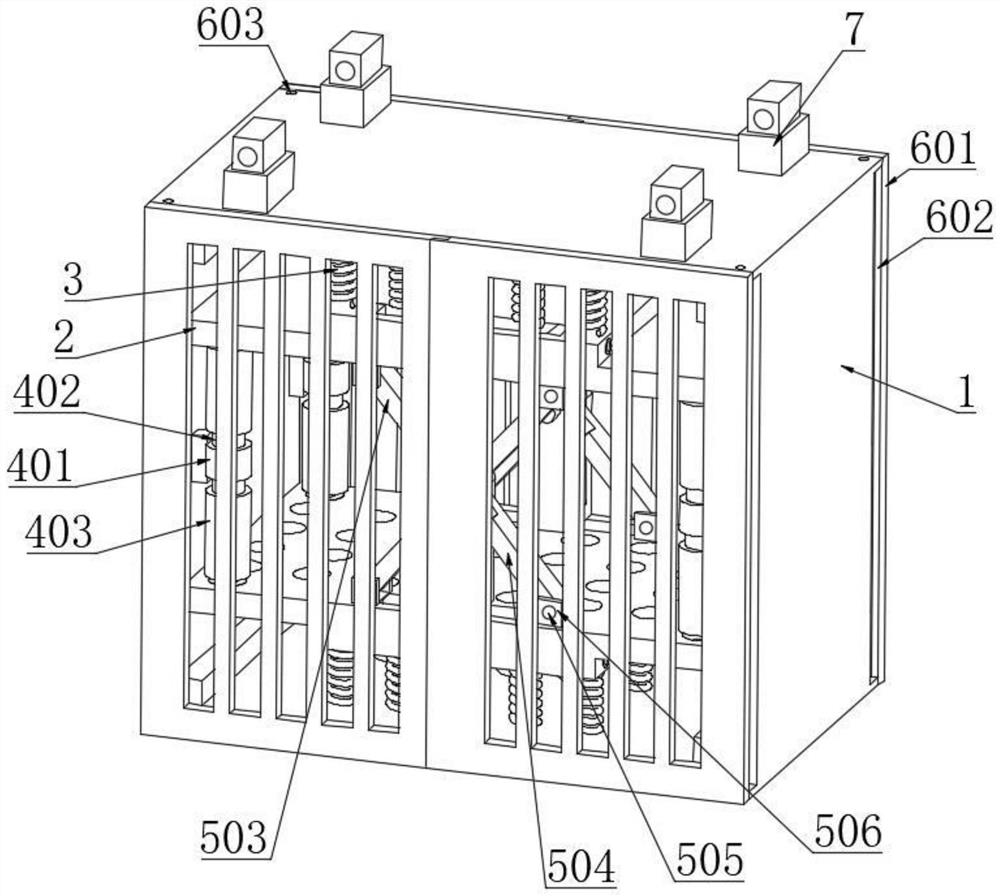

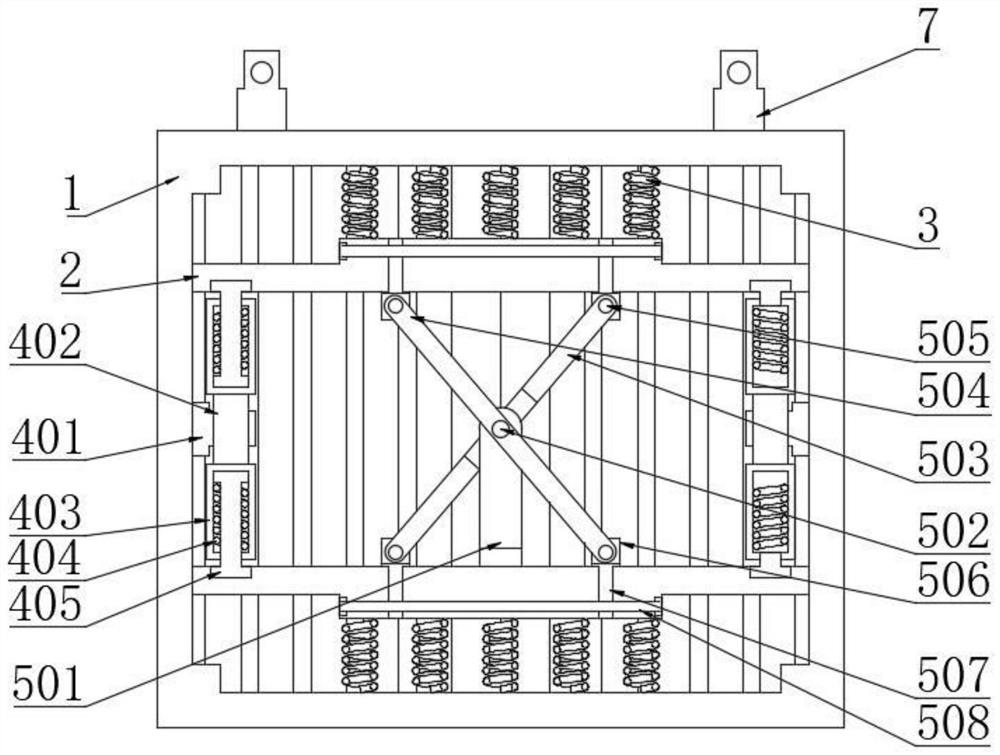

[0039] see Figure 1-7 , an oxygen acetylene safe transport cage, comprising cage 1, and also comprising,

[0040] Two symmetrically arranged limit frames 2: the two limit frames 2 are movably installed inside the cage body 1, and a plurality of compression springs 3 are installed on the outer end face of each limit frame 2; The spacer 2 can achieve the purpose of installing and storing the bottle body, so as to ensure the actual use effect, and under the action of multiple compression springs 3, it can always ensure the purpose of clamping the bottle body by the limiter 2, thereby ensuring the actual use effect. use effect.

[0041]Four limit mechanisms 4: The four limit mechanisms 4 are installed between the two limit frames 2, and the four limit mechanisms 4 are located at the four corners of the limit frame 2, and each limit mechanism 4 includes a fixing piece 401, the inner end surface of the fixing member 401 is connected with a fixing column 402, the two ends of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com