Efficient biogas residue aerobic composting reactor

A composting reactor and aerobic composting technology, applied in the application, organic fertilizer, fertilization device and other directions, can solve the problems of difficult to control fertilizer quality, prone to anaerobic environment, and large secondary pollution of the environment, so as to reduce heat. Loss, simple and efficient operation, easy to collect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to easily understand the technical means, creation features, achievement goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

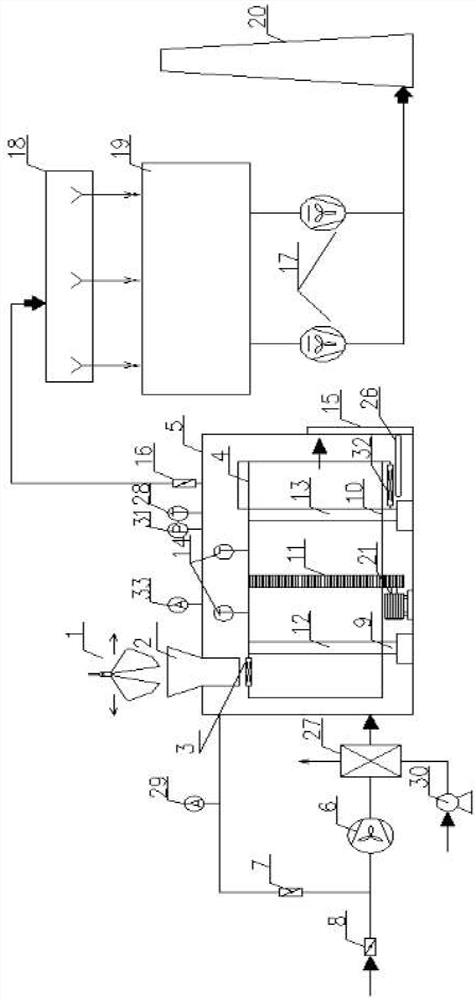

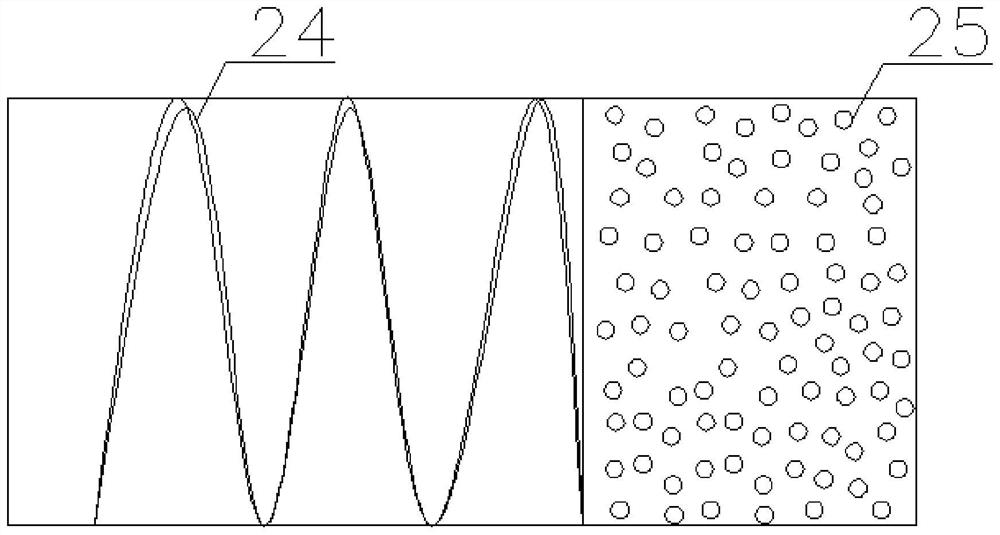

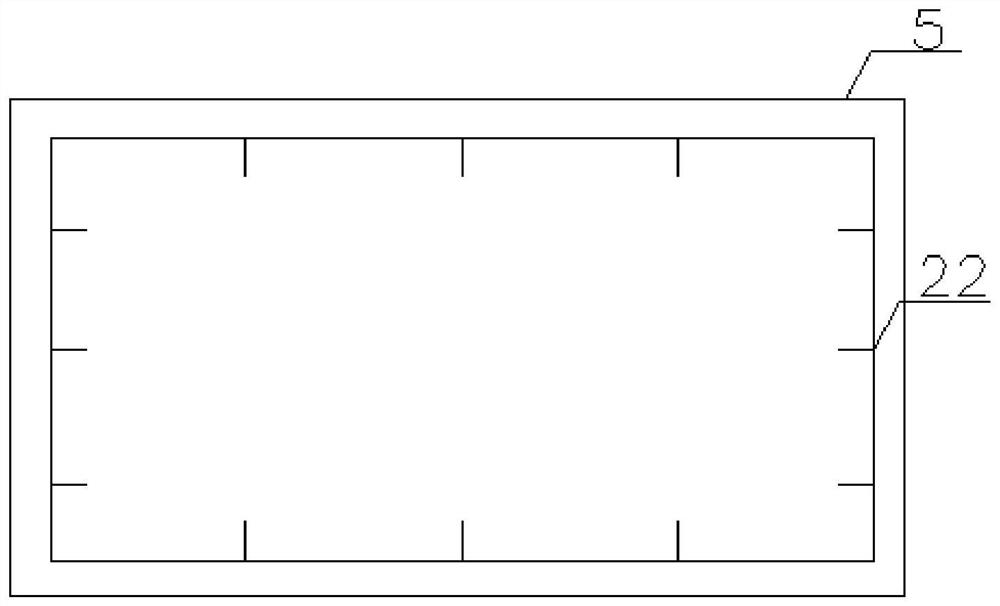

[0025] like Figure 1-4 As shown, a high-efficiency biogas residue aerobic composting reactor includes an outer shell 5 of the reactor and a cylindrical composting reactor body 4, and the outer shell 5 of the reactor is equipped with an oxygen supply component, an odor collection component and a thermal insulation component, The cylindrical composting reactor body 4 is located in the inner cavity of the outer shell 5 of the reactor. The axis of the cylindrical composting reactor body 4 is parallel to the horizontal plane. The cylindrical structure includes a side wall with a circular cross-section of the inner cavity and circular plates at both ends of the side wall. The side wall and the two circular plates on the two end faces form a hollow cylinder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com