Two-phase thixotropic agent and preparation method thereof

A thixotropic agent and solvent technology, which is applied in the field of two-phase thixotropic agent and its preparation, can solve the problems such as the inability to use multiple thixotropic agents in one agent, the large gap in suspension performance, and the inability to be used in general, and achieve the effect of good suspension effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] To prepare the thixotropic agent for two-phase use, the required raw materials are shown in Table 1.

[0059] Table 1 Example 1 raw material table

[0060]

[0061]

[0062] It should be noted that in 49 parts of polymer powder (containing negatively charged microorganisms), microorganisms accounted for 2%; in 1.5 parts of modified montmorillonite (containing nutrients), nutrients accounted for 30%.

[0063] The preparation method of the two-phase thixotropic agent: put the white oil into the reaction vessel, control the stirring rate at 300r / min, add cationic surfactant and anionic surfactant in sequence, stir for 10 minutes after the addition, and then adjust the stirring rate To 5000r / min, add modified montmorillonite and stir for 20 minutes.

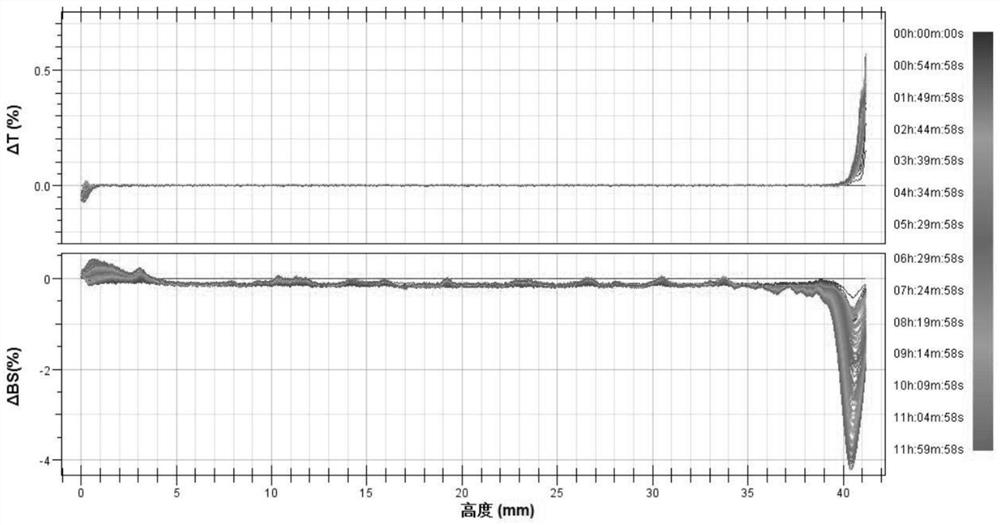

[0064] Preparation of Suspension System: Adjust the stirring speed of the two phases to 300 r / min with a thixotropic agent, add polymer powder, and stir for 30 minutes to complete the preparation of the suspension syste...

Embodiment 2

[0067] To prepare a thixotropic agent for two-phase use, the required raw material table is shown in Table 2.

[0068] Table 2 Example 2 raw material table

[0069]

[0070] It should be noted that in 28 parts of biocolloid powder (containing negatively charged microorganisms), microorganisms accounted for 2%; in 1.5 parts of modified montmorillonite (containing nutrients), nutrients accounted for 30%.

[0071] The preparation method of two-phase thixotropic agent:

[0072] Put kerosene into the reaction vessel, control the stirring speed at 200r / min, add cationic surfactant and anionic surfactant in turn, stir for 10 minutes after the addition, adjust the stirring speed to 4000r / min, add modified montmorillonite , stir for 20 minutes.

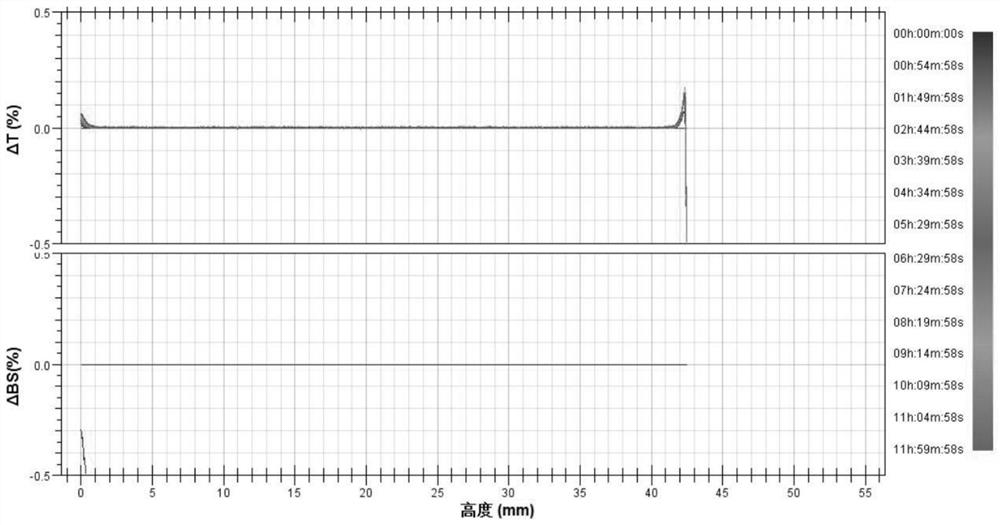

[0073] Preparation of Suspension System: Adjust the stirring speed of the two phases to 200 r / min with a thixotropic agent, add polymer powder, and stir for 30 minutes to complete the preparation of the suspension system.

Embodiment 3

[0075] To prepare the thixotropic agent for two-phase use, the required raw material table is shown in Table 3.

[0076] Table 3 Example 3 raw material table

[0077]

[0078] It should be noted that in 32 parts of polymer powder (containing negatively charged microorganisms), microorganisms accounted for 2%; in 1.5 parts of modified montmorillonite (containing nutrients), nutrients accounted for 30%.

[0079] The preparation method of the two-phase thixotropic agent: put polyethylene glycol 200 into the reaction vessel, control the stirring speed at 500r / min, add cationic surfactant and anionic surfactant in turn, stir for 10 minutes after the addition, and then Adjust the stirring speed to 6000r / min, add modified montmorillonite, and stir for 20 minutes.

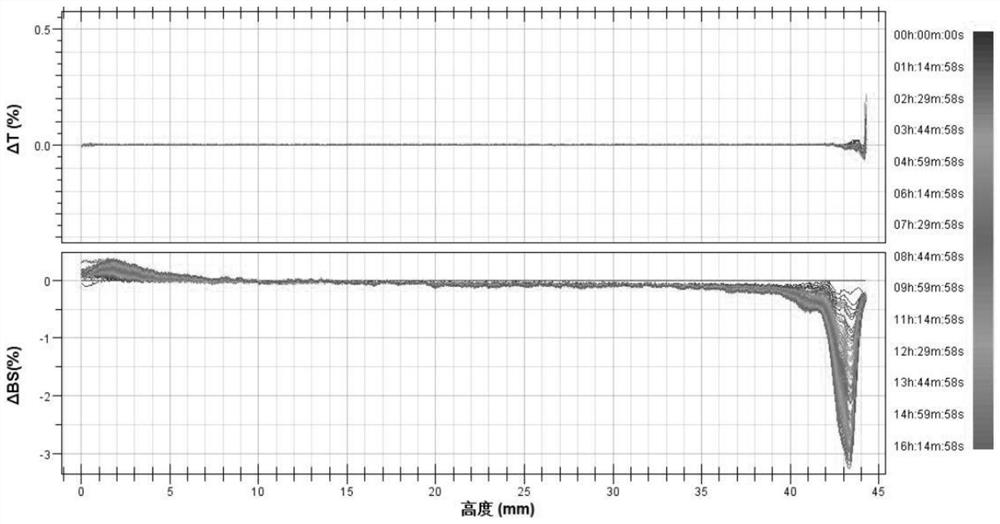

[0080] Preparation of Suspension System: Adjust the stirring speed of the two phases to 400 r / min with a thixotropic agent, add polymer powder, and stir for 30 minutes to complete the preparation of the suspension syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com