Oriented fiber UHPC (Ultra High Performance Concrete) bridge deck slab for hogging moment area of steel-concrete composite beam and preparation and construction method

A technology of steel-concrete composite beams and negative moment areas, which is applied in the manufacture of tools, bridges, bridge parts, etc., can solve the problems of high cost and waste of fiber materials, and achieve environmental protection of materials, reduction of consumption, and good continuity of structural strength and rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The oriented fiber UHPC bridge deck in the negative bending moment area of a steel-concrete composite beam according to the present invention, its construction method can be carried out according to the following steps:

[0062] 1) According to the calculation and analysis results of the bridge and the actual situation of the project, determine the arrangement length and thickness distribution of the directional fiber UHPC bridge deck 1 of the stepped longitudinal bridge in the negative bending moment area, and determine the arrangement of ordinary steel bars and U-shaped connecting steel bars;

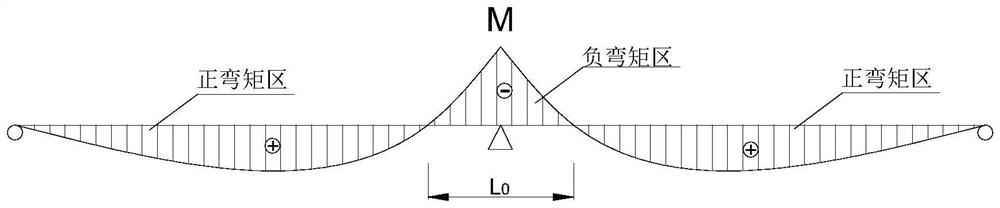

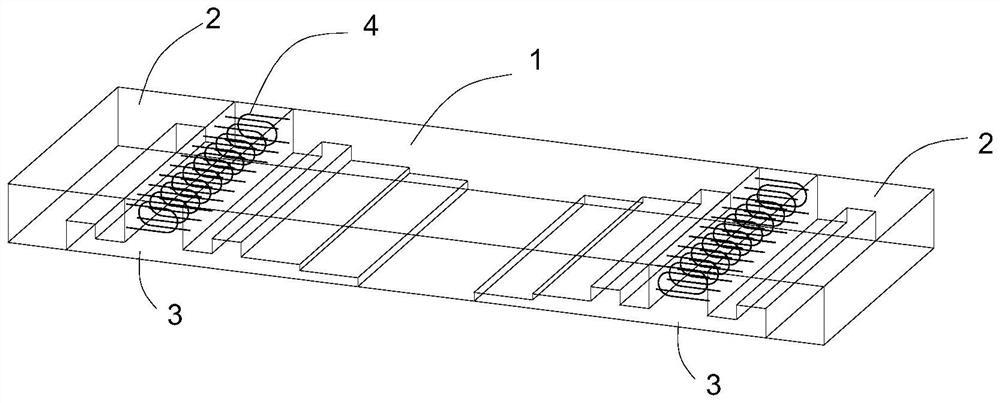

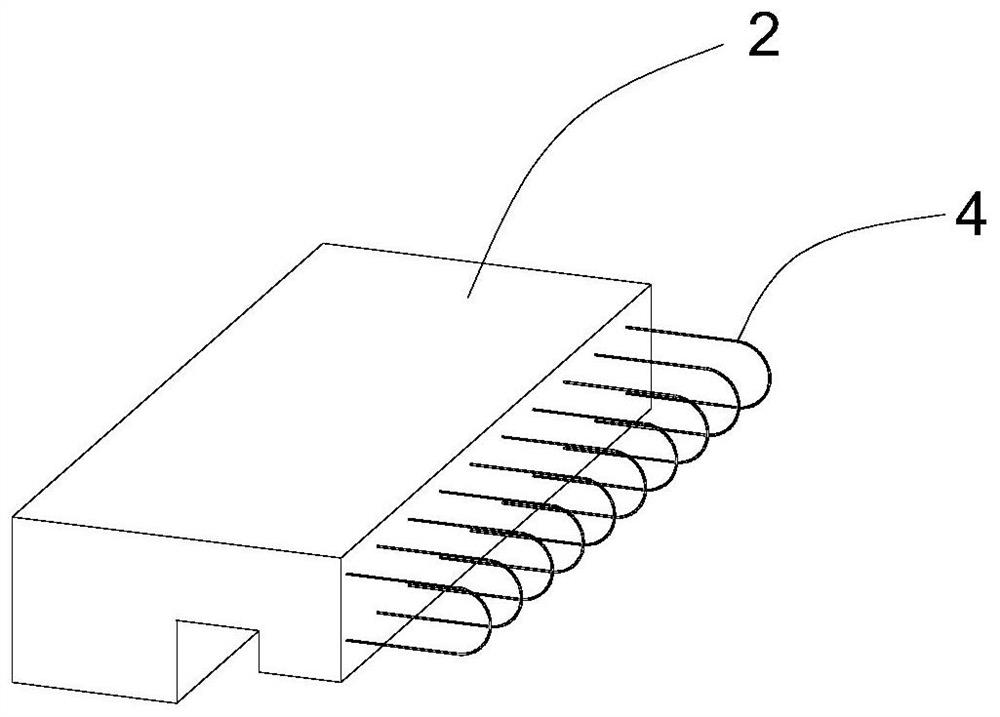

[0063] 2) as Image 6 As shown, it is a schematic structural diagram of a bridge deck provided by an embodiment of the present invention. according to figure 1 For the force conditions shown, the entire negative moment length is L 0 , the total height of the bridge deck is h 0 , the maximum negative bending moment is M, and the size of the oriented fiber UHPC bridge deck i...

Embodiment 2

[0068] The oriented fiber UHPC bridge deck in the negative bending moment area of the steel-concrete composite beam of the present invention, its construction method can be carried out according to the following steps:

[0069] Step 1. Determine the range of different negative bending moments in the bridge, determine the central thickness of the directional fiber UHPC bridge deck 1 in the negative bending moment area and the longitudinal thickness of the plate body; determine the width and depth of the grooves at both ends of the longitudinal direction;

[0070] Step 2, forming a pouring mold based on the size of the oriented fiber UHPC bridge deck (1) in the bending moment zone determined in step 1;

[0071] The preparation parameters of the mold are as follows: figure 1 and Image 6 The entire negative bending moment length shown is L 0 , the total height of the bridge deck is h 0 , the maximum negative bending moment is M, and the size of the oriented fiber UHPC bridge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com