House building construction concrete flattening device and using method thereof

A technology of concrete and flat rollers, applied in construction, building structure, construction material processing and other directions, can solve the problems of premature freezing of concrete, concrete freezing, affecting the leveling effect of the device, etc., to prevent premature freezing and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

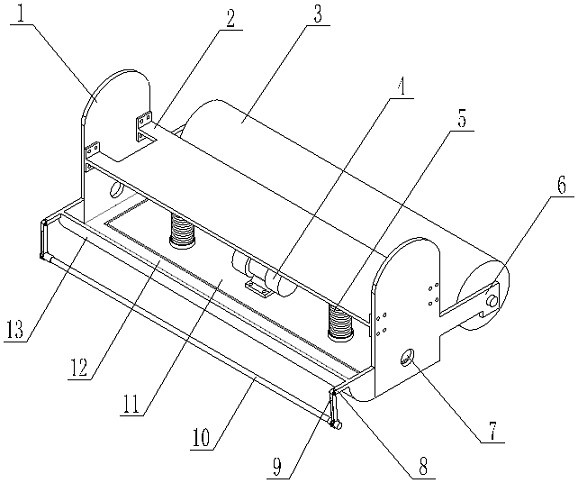

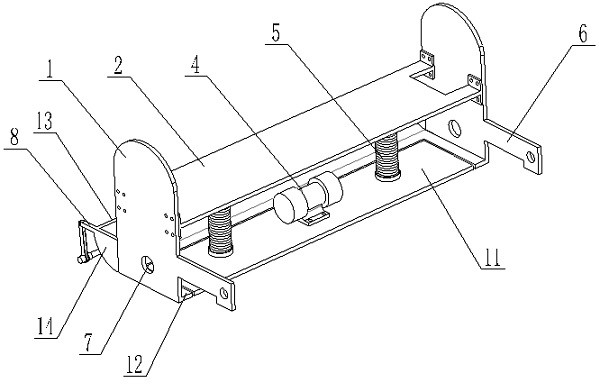

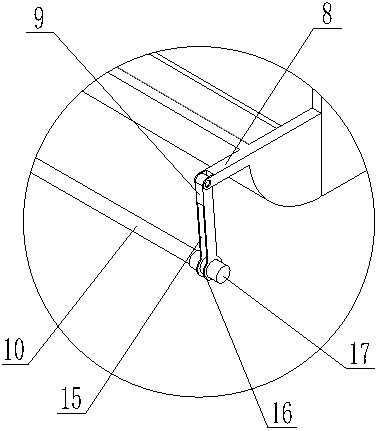

[0061] A concrete leveling device for building construction of the present invention is composed of a main body component, a pounding component and a heating component.

[0062] The main body assembly consists of a support frame (1), a flattening roller (3), a flattening roller mounting plate (6), a reserved traction hole (7), an anti-sinking plate (12), a waterproof baffle (13), a fixed The plate (14) and the pounding groove (18) are composed,

[0063] The two support frames (1) are correspondingly placed at both ends of the anti-sinking plate (12),

[0064] Preferably, the anti-sinking plate (12) has a rectangular structure

[0065] Preferably, one end of the support frame (1) is a rectangular structure, and the other end is a semicircular structure,

[0066] The anti-sinking plate (12) is provided with a pounding groove (18),

[0067] Preferably, the pounding groove (18) is a rectangular structure, and the pounding groove (18) is a through groove,

[0068] There are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com