Tower drum fatigue load accumulation method and system based on wind direction frequency distribution

A technology of fatigue load and wind direction frequency, which is applied in the monitoring of wind turbines, the configuration of installing/supporting wind turbines, wind turbines, etc., can solve unconsidered problems, reduce fatigue damage, reduce equivalent fatigue loads, and lower towers Effect of Barrel Weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

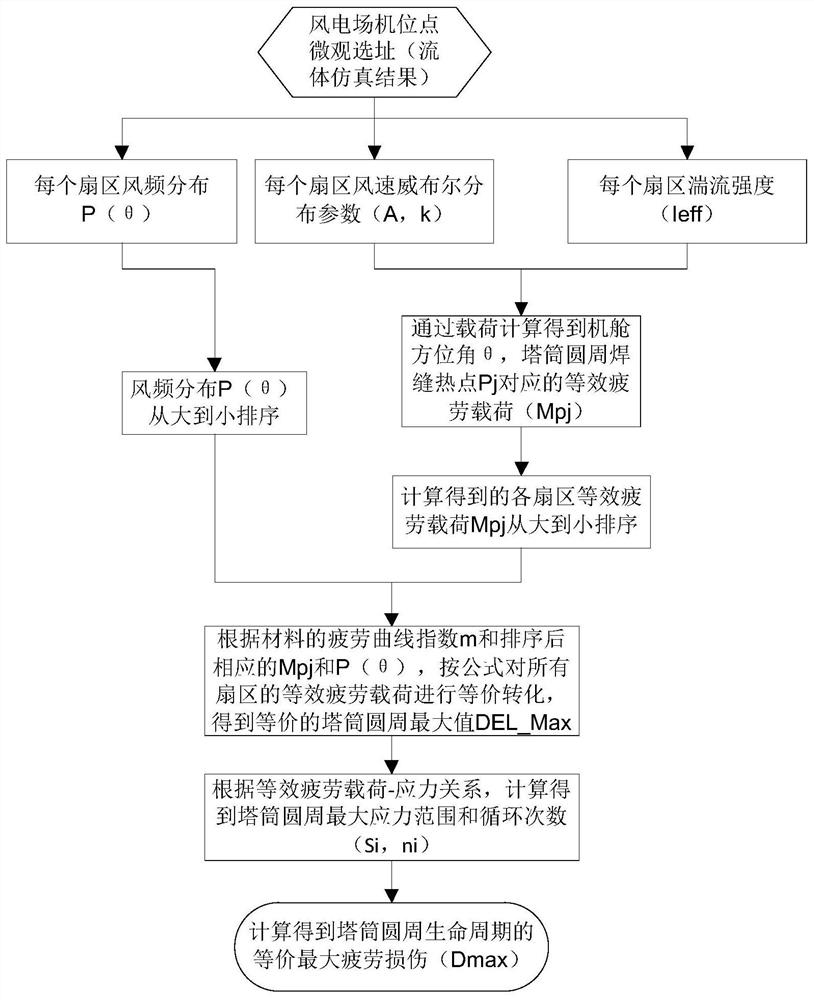

[0031] like figure 2 As shown, the tower fatigue load accumulation method based on the wind direction frequency distribution of this embodiment includes the steps:

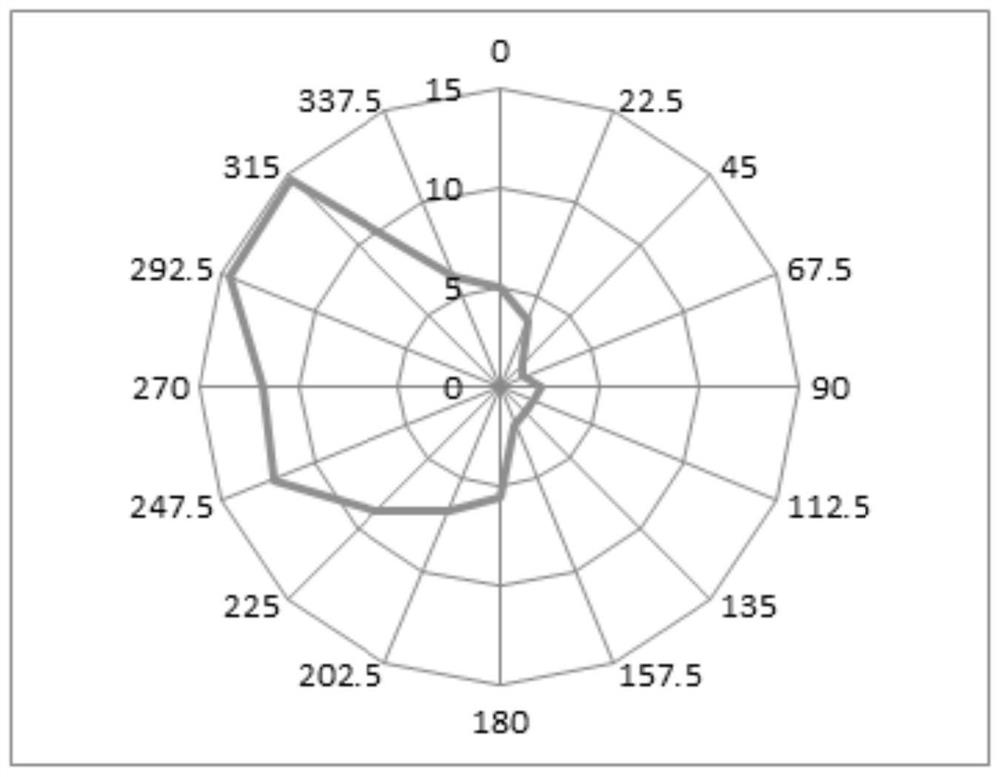

[0032] S1. Obtain the wind frequency distribution P(θ) of each sector of the specific site site, the Weibull distribution parameters (A, k) of each sector, and the effective turbulence intensity Ieff of each sector;

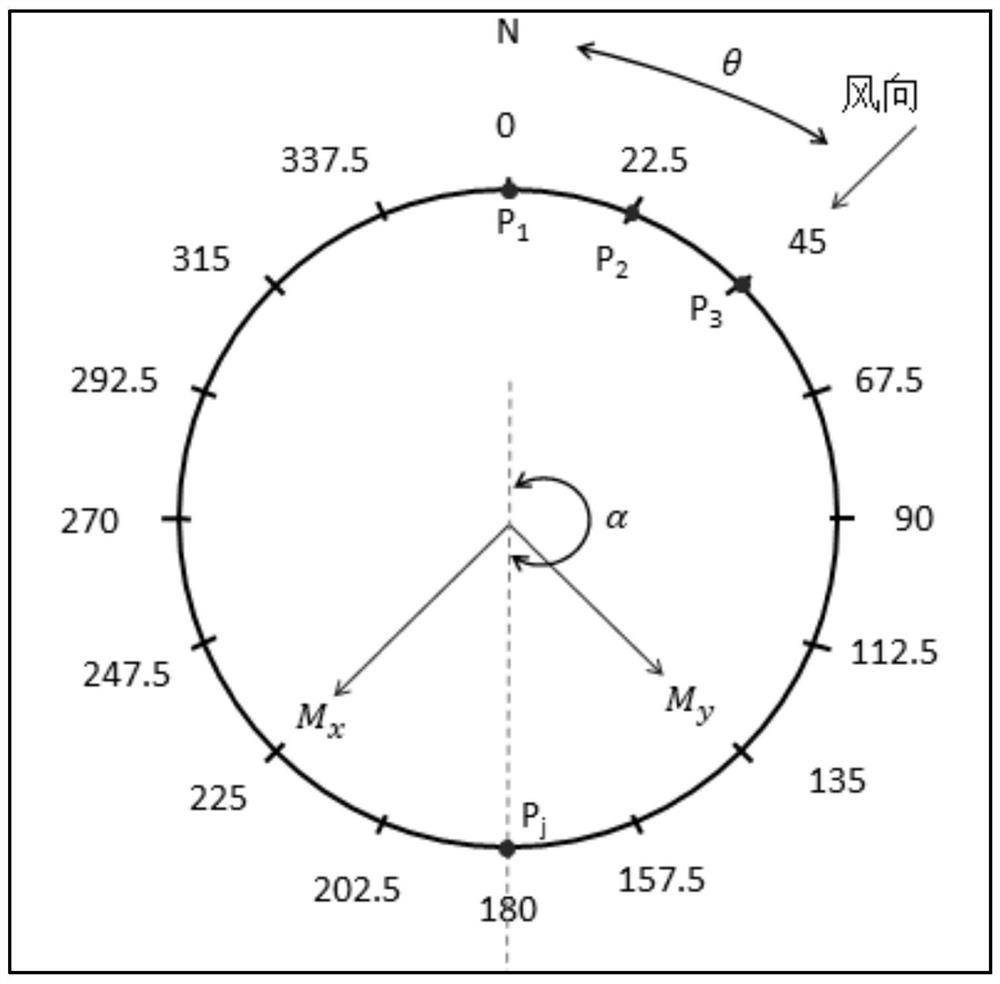

[0033] S2. Through the load calculation, the azimuth angle θ of the engine room and the hot spot P of the circumferential weld of the tower are obtained. j Corresponding equivalent fatigue load M pj (θ);

[0034] S3. Sort the wind frequency distribution P(θ) of each sector; the hot spot P of the circumferential weld of the tower j Corresponding equivalent fatigue load M pj (θ) Sorting; according to the fatigue curve index m of the material and the corresponding M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com