Efficient freezing vacuum system for fatty acid processing

A vacuum system, fatty acid technology, applied in lighting and heating equipment, machine operation, machines using refrigerant evaporation, etc., can solve the problems of high energy consumption, large steam consumption, etc., to increase the amount of liquefaction, reduce The output volume, the effect of the equipment drainage response is sensitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

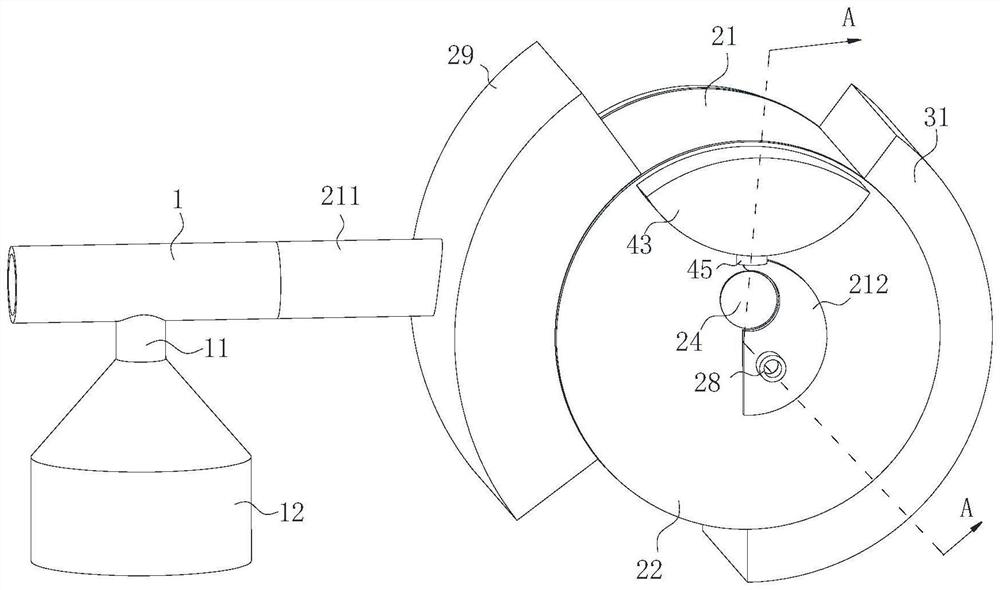

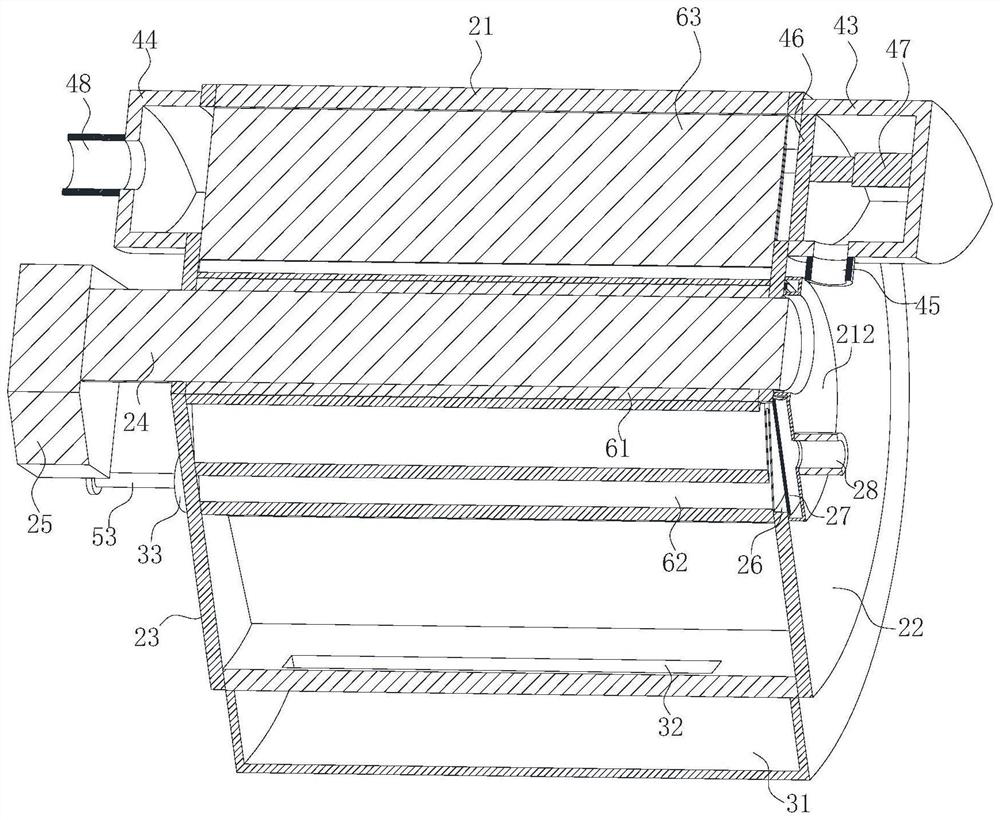

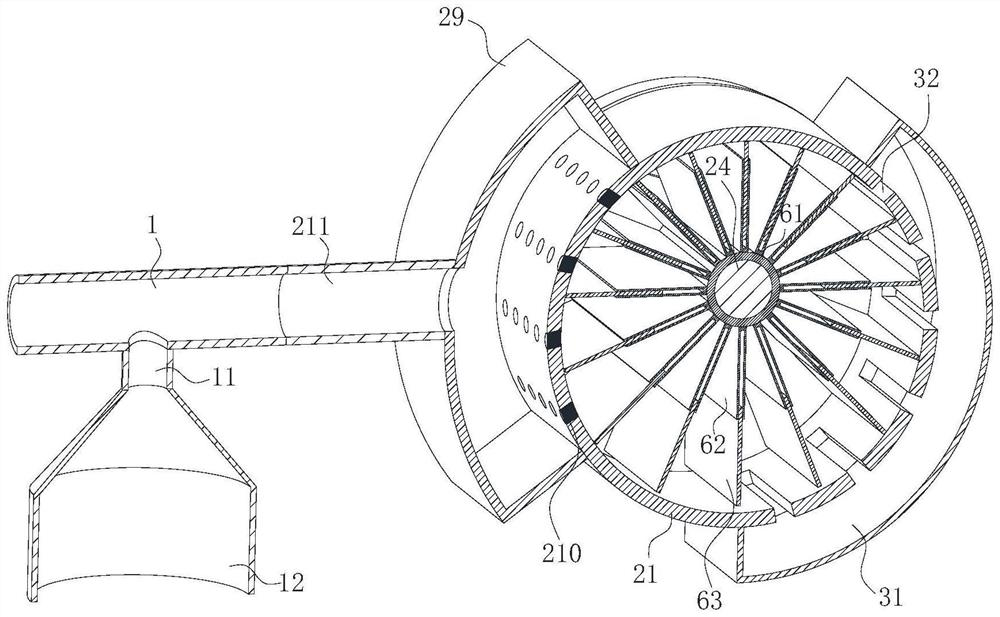

[0028] see Figure 1-8 , the present invention provides a technical solution: a high-efficiency freezing vacuum system for fatty acid processing, comprising a first pipeline 1, an external reaction kettle, an external power steam source and a water ring vacuum pump, the left end of the first pipeline 1 is connected to the power steam The right end of the first pipeline 1 is connected to the intake end of the water ring vacuum pump, the lower side wall of the first pipeline 1 is connected to the reactor, and the water ring vacuum pump can continuously replace the liquid in the pump with low temperature liquid.

[0029]During operation, the power steam source flows at high speed in the first pipeline 1 from left to right, and drives the gas in the reaction kettle to flow at a high speed in the process of circulation, and then forms a suction effect on the reaction kettle, so that the pressure in the reaction kettle drops, The boiling point in the reaction kettle is lowered. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com