Solid oxide fuel cell (SOFC) glue discharging and sintering integrated furnace

A fuel cell and debinding technology, applied in electric furnace heating, furnace, furnace type, etc., can solve the problems of inconvenient replacement, high temperature in local directions, and inconvenient maintenance, and achieve the effect of improving convenience and heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

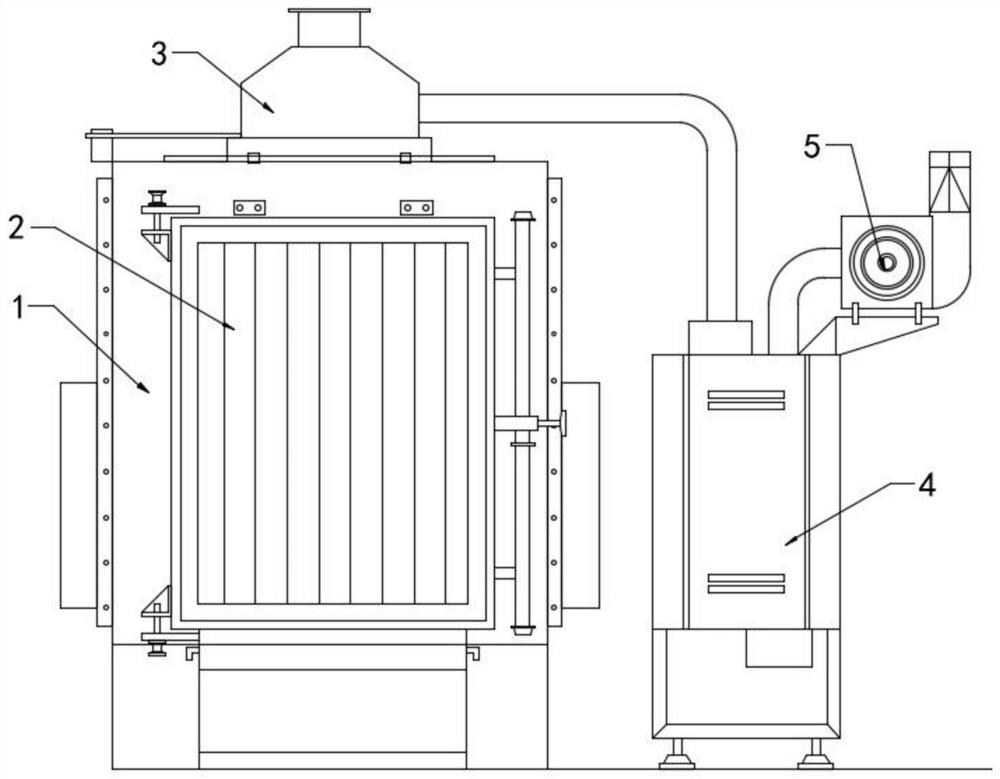

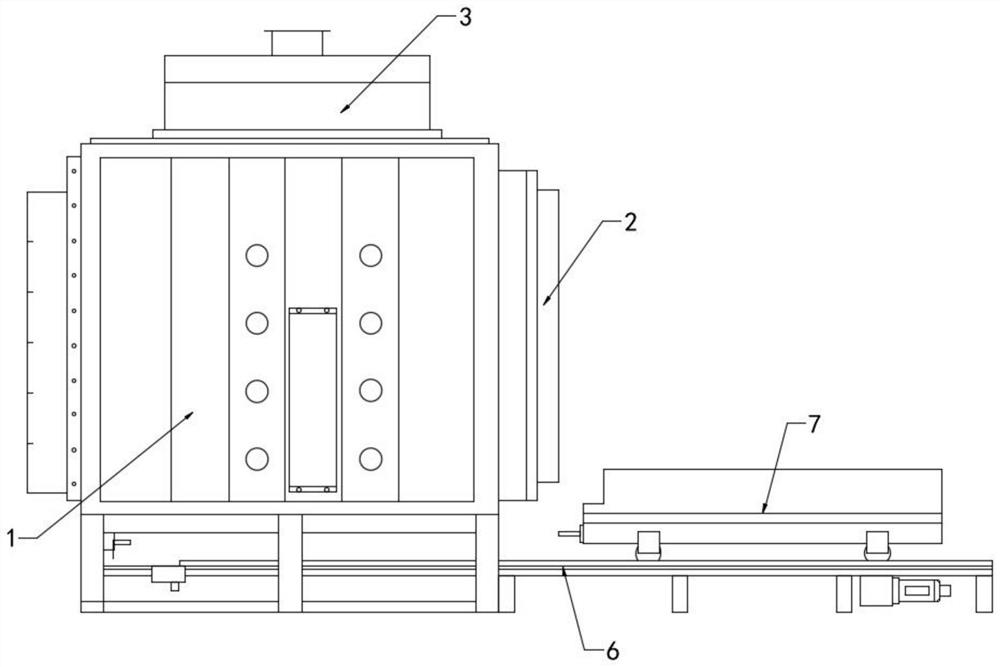

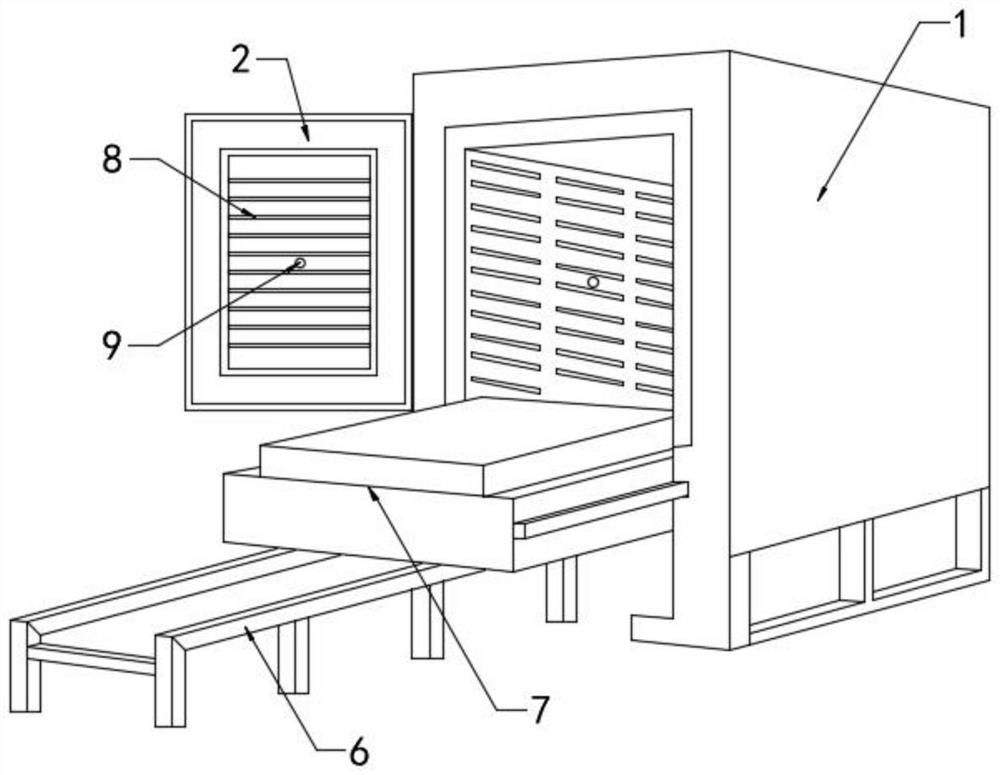

[0023] Attached to the following Figure 1-5 The present invention will be described in further detail.

[0024] The embodiment of the present invention discloses a SOFC solid-state fuel cell debinding and sintering integrated furnace. refer to Figure 1-5 , an SOFC solid-state fuel cell debinding and sintering integrated furnace, comprising a furnace body 1 with a double-layer mechanism, the furnace body 1 of the furnace body is made of lightweight foam bricks, and the heat insulation properties of the lightweight foam bricks are utilized, and the furnace body 1 furnace Cut buckles are reserved on the five inner walls of the furnace body 1. Preferably, the furnace body 1 is located on the outer side of the foam brick and is provided with a steel plate, and the steel plate is a double-layer structure with a ventilation opening at the bottom, thereby reducing the surface temperature of the outer side of the furnace body 1 and increasing the temperature. The safety of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com