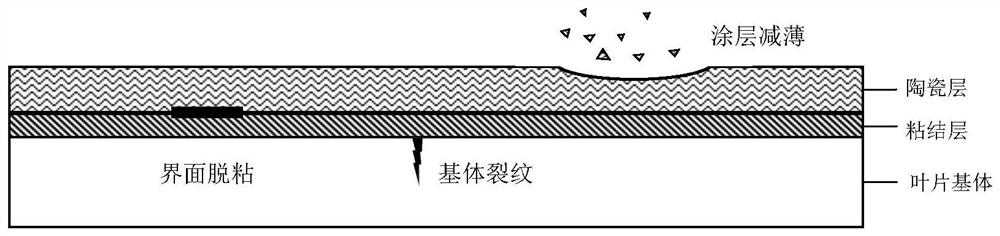

Eddy current infrared integrated detection system and method for typical defects of thermal barrier coating of reignition blade

A technology of thermal barrier coating and detection system, which is applied in the direction of material defect testing, radiation pyrometry, measuring devices, etc., to achieve the effects of improving detection efficiency, enhancing detection effect, and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the accompanying drawings.

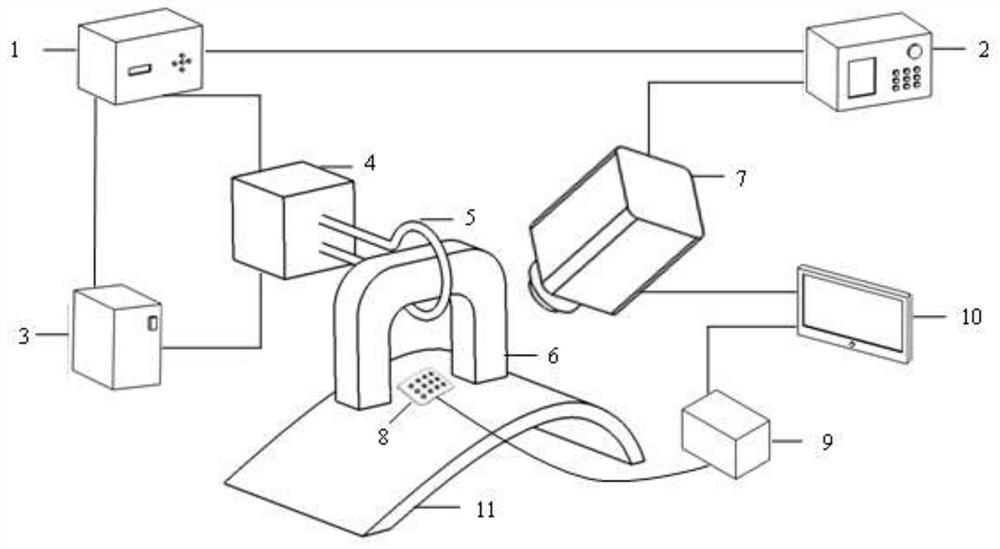

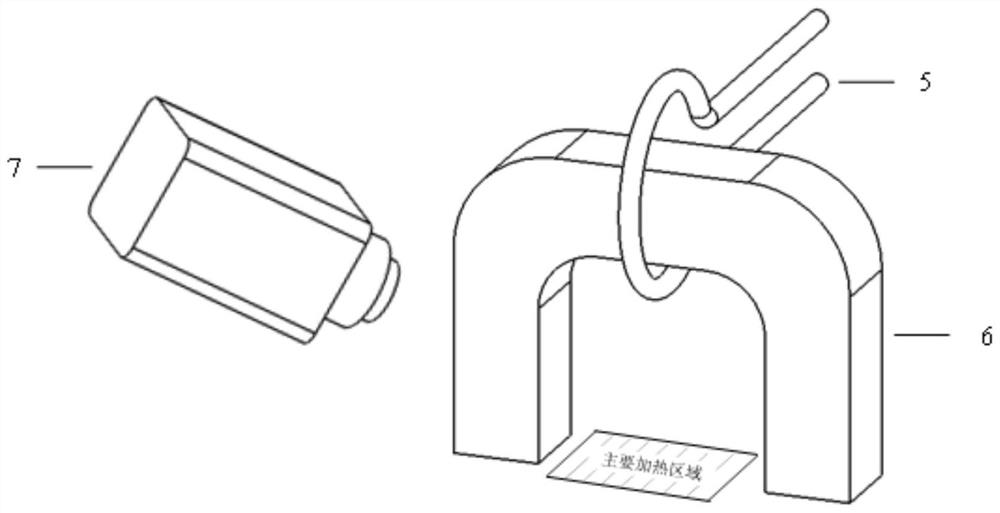

[0027] like figure 1 and figure 2 As shown in the figure, the eddy current infrared integrated detection system for typical defects of thermal barrier coatings of reburned blades provided by the present invention includes a signal excitation device 1, a synchronous trigger device 2, a water cooling device 3, a heating head 4, an excitation coil 5, and a magnetic yoke. 6. Infrared camera 7 , array detection coil 8 , lock-in amplifier 9 , computer 10 and reburning blade 11 . The signal excitation device 1 is connected to the synchronous trigger device 2, and is connected to the excitation coil 5 through the heating head 4; the water cooling device 3 is connected to the excitation coil 5, and the yoke 6 passes through the excitation coil 5 and is placed on the surface of the reburning blade 11; The coil 8 is placed on the surface of the reburning blade 10 adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com