Current and voltage integrated sensor

A technology that integrates sensors, current and voltage, and is used in the measurement of current/voltage, instruments, and electrical variables. problem, to avoid deviation, protect intact, prevent skin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

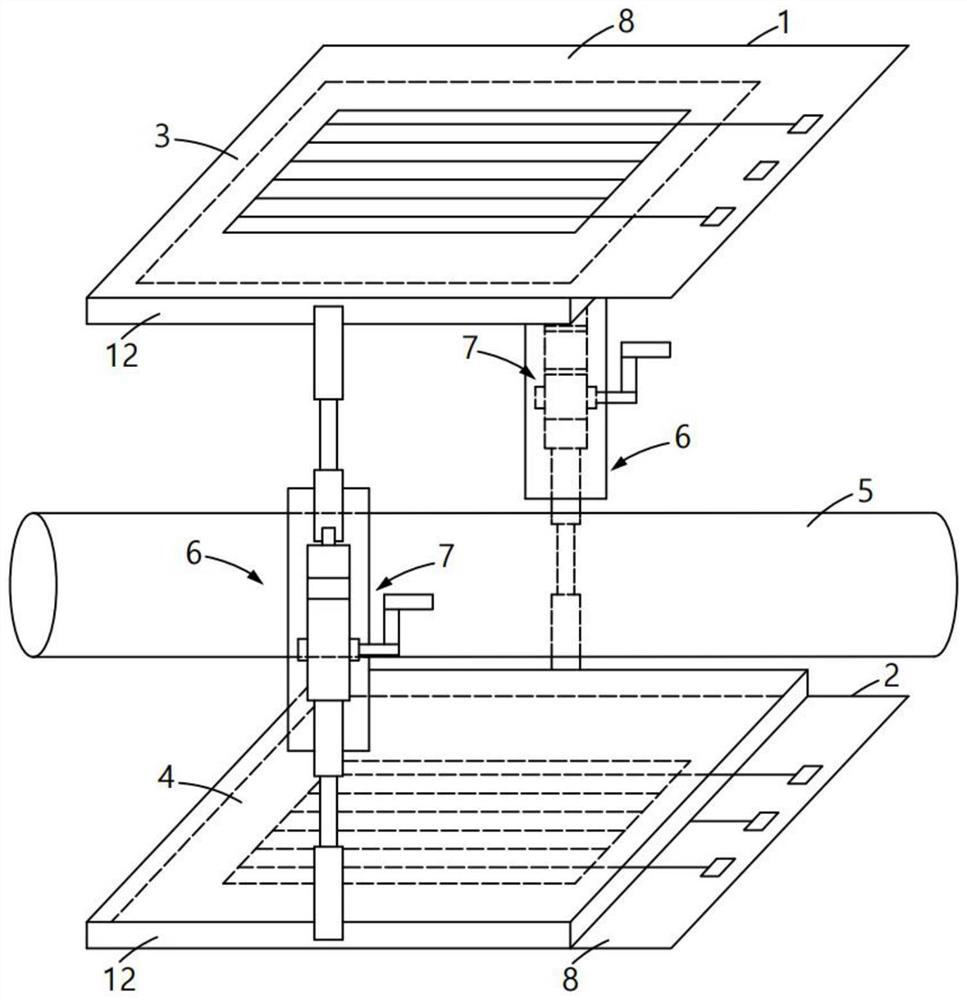

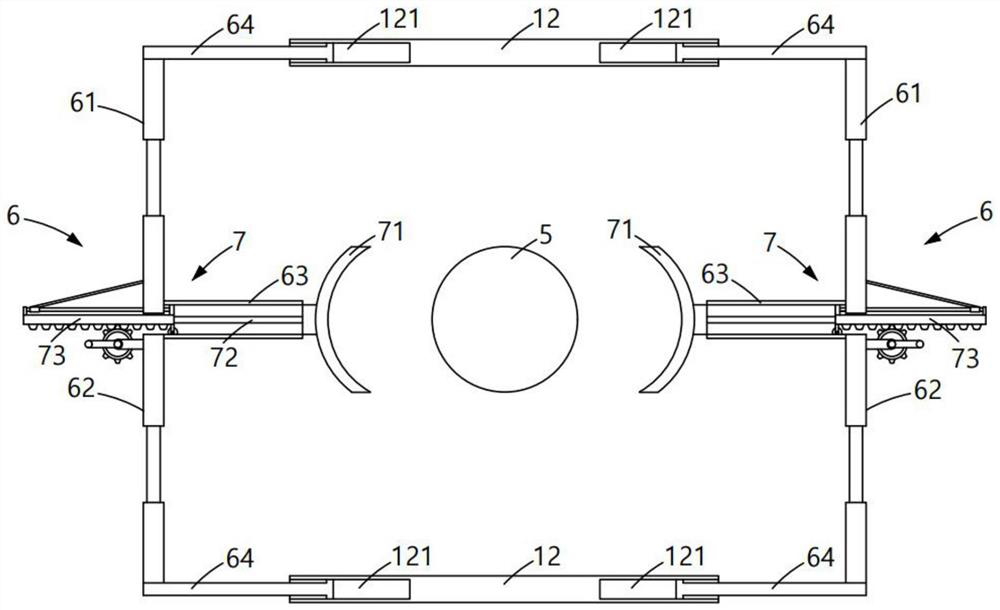

Embodiment 1

[0031]The current and voltage integrated sensor can detect the current signal and voltage signal of the AC distribution network at the same time. Among them, the working principle of the current sensor 3 is Faraday's law of electromagnetic induction. The alternating magnetic field generated by the AC signal in the transmission wire 5 passes through the magnetic core coil 9 to generate an induced electromotive force at both ends of the magnetic core coil 9, and the electromotive force is proportional to the measured current. , the magnitude of the measured current can be obtained through the electromotive force; the working principle of the voltage sensor 4 is the principle of electrostatic induction. The distance between the two metal layers 12 and the transmission wire 5 is different, and the number of induced charges is different. The difference between the induced charges can be used to obtain the alternating electric field generated by the transmission wire 5, and then the ...

Embodiment 2

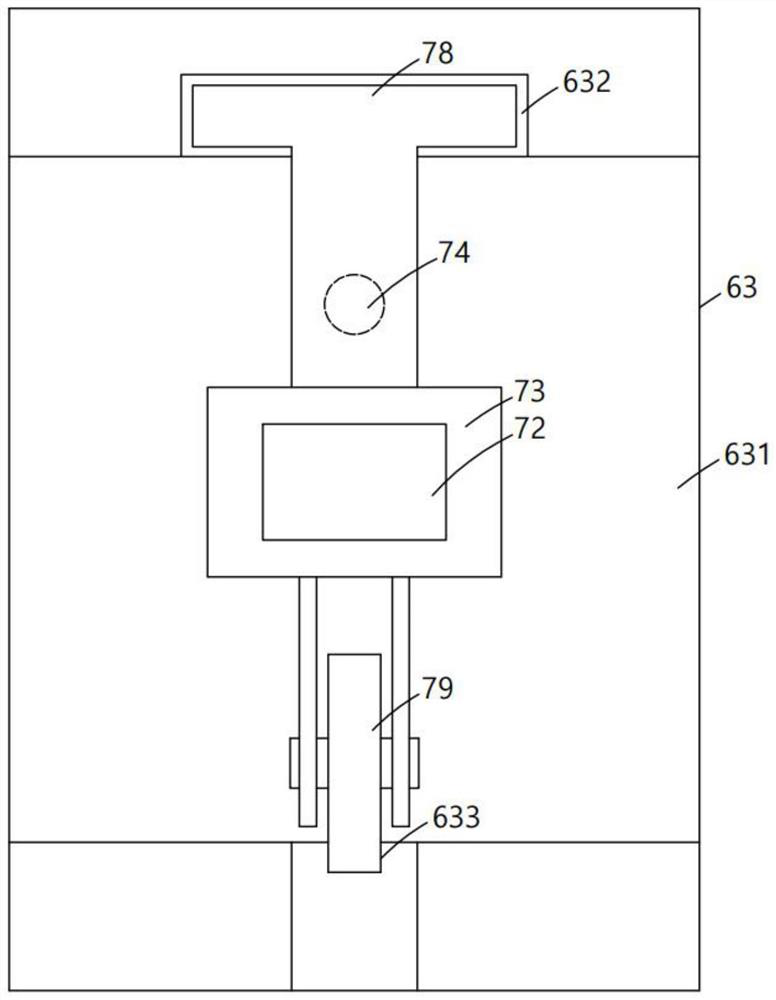

[0041] like Figure 5 As shown in 9 or 10, the difference between the second embodiment and the first embodiment is that the front and rear adjustment mechanisms on both sides of the first sensing part 1 and the second sensing part 2 include a gear adjustment mechanism 7 and a spring adjustment mechanism 13 , and the spring adjustment mechanism 13 includes a third telescopic rod 131, a fourth telescopic rod 132, a second adjusting rod 133 and a second push block 134, the third telescopic rod 131 and the fourth telescopic rod 132 are respectively fixedly installed on the The side wall of the metal layer 12 and the second adjusting rod 133 are fixedly installed on the outer walls of the third telescopic rod 131 and the fourth telescopic rod 132 , and a second space is opened inside the second adjusting rod 133 . The cavity 136, the sliding connection end of the second cavity 136 is provided with the movable rod 137 of the handle 142, one end of the movable rod 137 is elastically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com