Fitting method applied to sponge cutting file

A sponge cutting and file technology, which is applied in the field of sponge cutting file fitting, can solve problems such as the inability to solve the overall fitting of sponge cutting graphics, and achieve the effect of reducing length, improving speed and fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

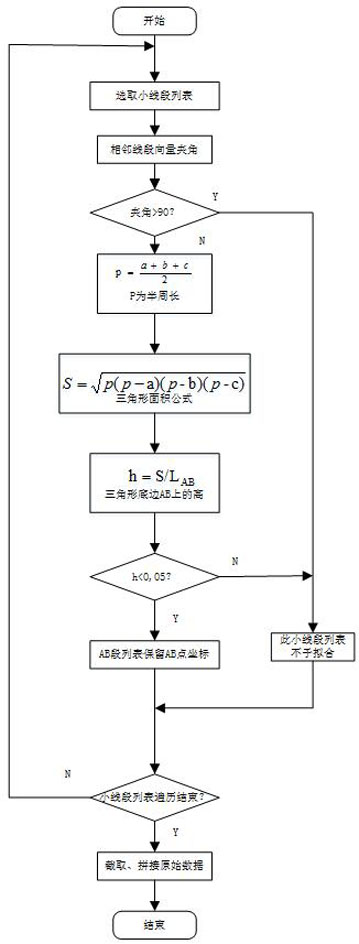

[0045] The fitting method applied to the sponge cutting file of the present invention is specifically realized through the following steps:

[0046] S1 data preprocessing: read the data in the cutting file, convert the data type, convert the string type to floating point type, remove the spaces in the cutting file, rewrite the cutting file into a data list with fixed format characteristics, define after rewriting The list of data is the first list.

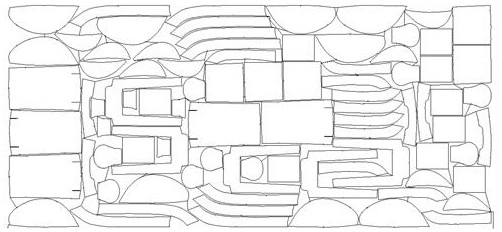

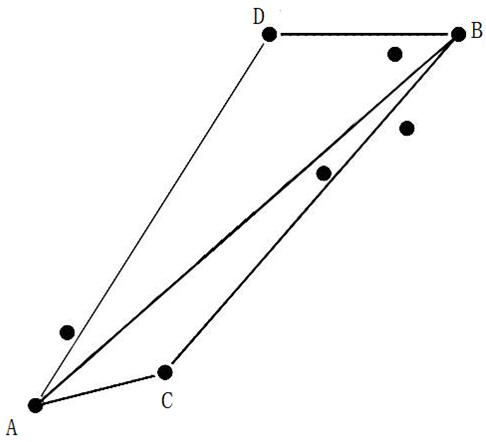

[0047] S2 closed figure split: There are several patterns to be cut on the same sponge. Based on the principle that a single sponge cutting pattern must be a closed figure, the starting point and the end point of the closed figure have the same coordinates, and there will be many more in the first list. Set the coordinates of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com