Environment-friendly cleaning equipment for solid waste treatment

A cleaning equipment and environmental protection technology, applied in the field of solid waste treatment and environmental protection cleaning equipment, can solve the problems of inability to pulverize solid waste, affect the collection of operators, and affect garbage disposal, so as to reduce unpleasant smell, improve processing efficiency, and facilitate disposal The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

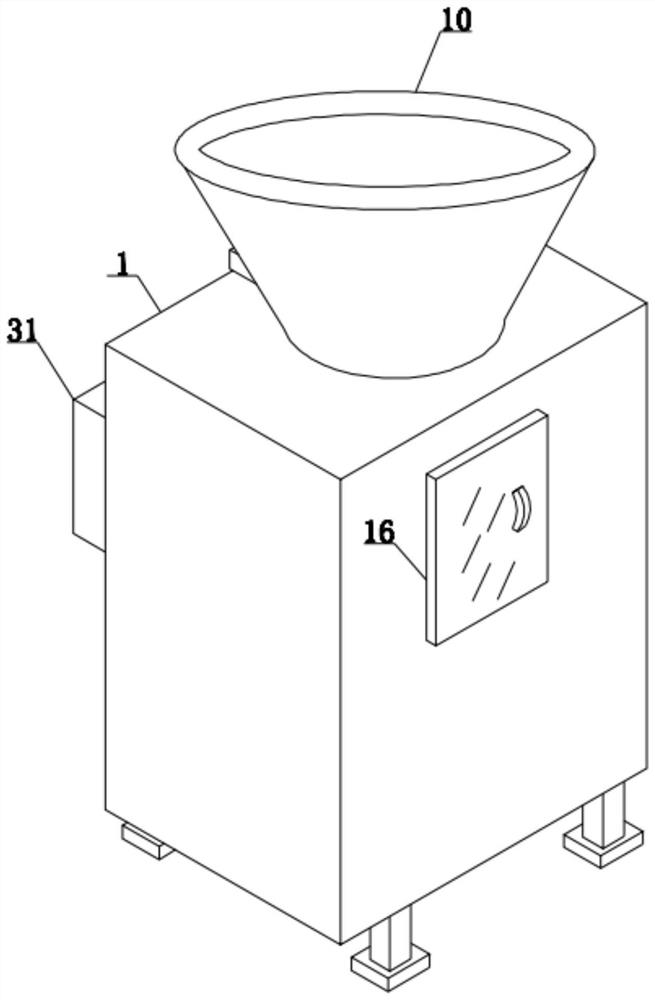

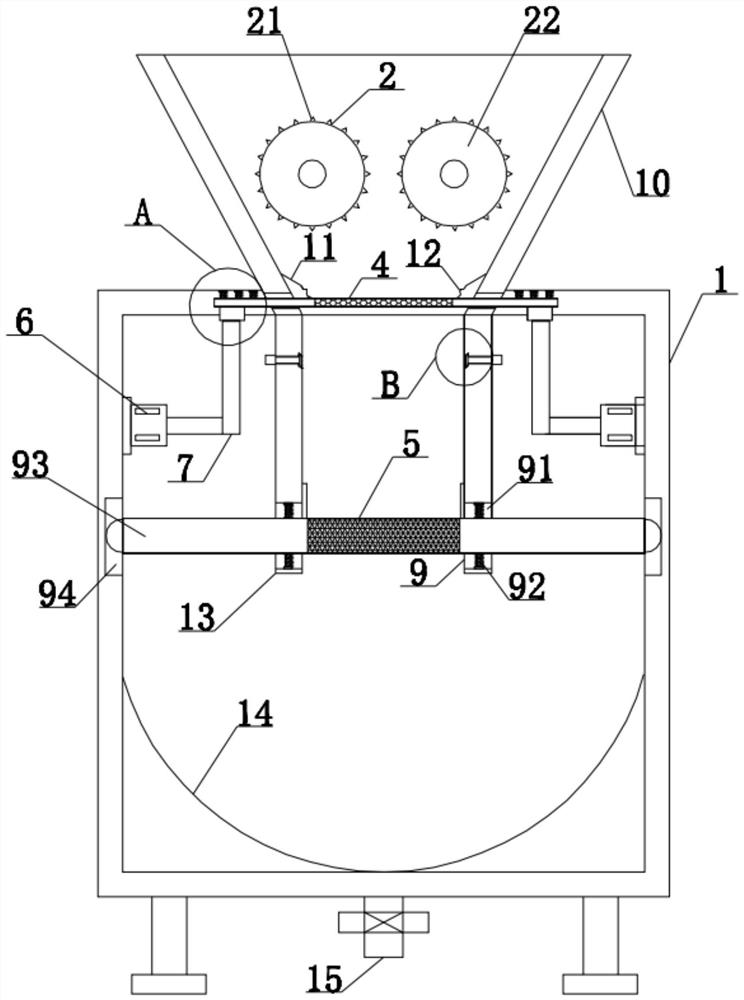

[0037] refer to Figure 1-5, The environmental protection cleaning equipment for solid waste treatment described in this embodiment includes a casing 1, a feeding hopper 10 is fixedly connected to the middle of the upper end of the casing 1, and a pulverizing component 2 is arranged inside the feeding hopper 10. The assembly 2 includes a pulverizing roller 21, which is rotatably connected to the interior of the feeding hopper 10. There are two groups of pulverizing rollers 21. The outer surface of the pulverizing roller 21 is fixedly connected with pulverizing teeth 22. The hopper 10, the rear side of the feeding hopper 10 is equipped with a pulverizing motor, one side of the pulverizing motor and one side of the pulverizing roller 21 are fixed by a coupling, the pulverizing motor is used to drive the pulverizing roller 21 to rotate, and the pulverizing roller 21 drives the pulverizing teeth 22 The garbage in the feeding hopper 10 is crushed. The feeding hopper 10 is movably c...

Embodiment 2

[0039] refer to figure 2 and Figure 4 , on the basis of Embodiment 1, in order to achieve the purpose of making the material guide plate 4 move while making the liquid guide plate 5 move, this embodiment has carried out an innovative design for the first linkage assembly 8 and the second linkage assembly 9, specifically, The first linkage assembly 8 includes a first spring 81. The first spring 81 is fixedly connected to the interior of the upper cavity of the housing 1. The bottom end of the first spring 81 is fixedly connected with a first linkage rod 82. One side passes through the feeding hopper 10 and is fixedly connected to one end of the guide plate 4, the lower end side of the first linkage rod 82 is fixedly connected to the driving block 83, and the cam plate 7 is movably connected to one side of the driving block 83 through the driving motor 6 , the second linkage assembly 9 includes a through hole 91, the through hole 91 is opened inside the left and right sides o...

Embodiment 3

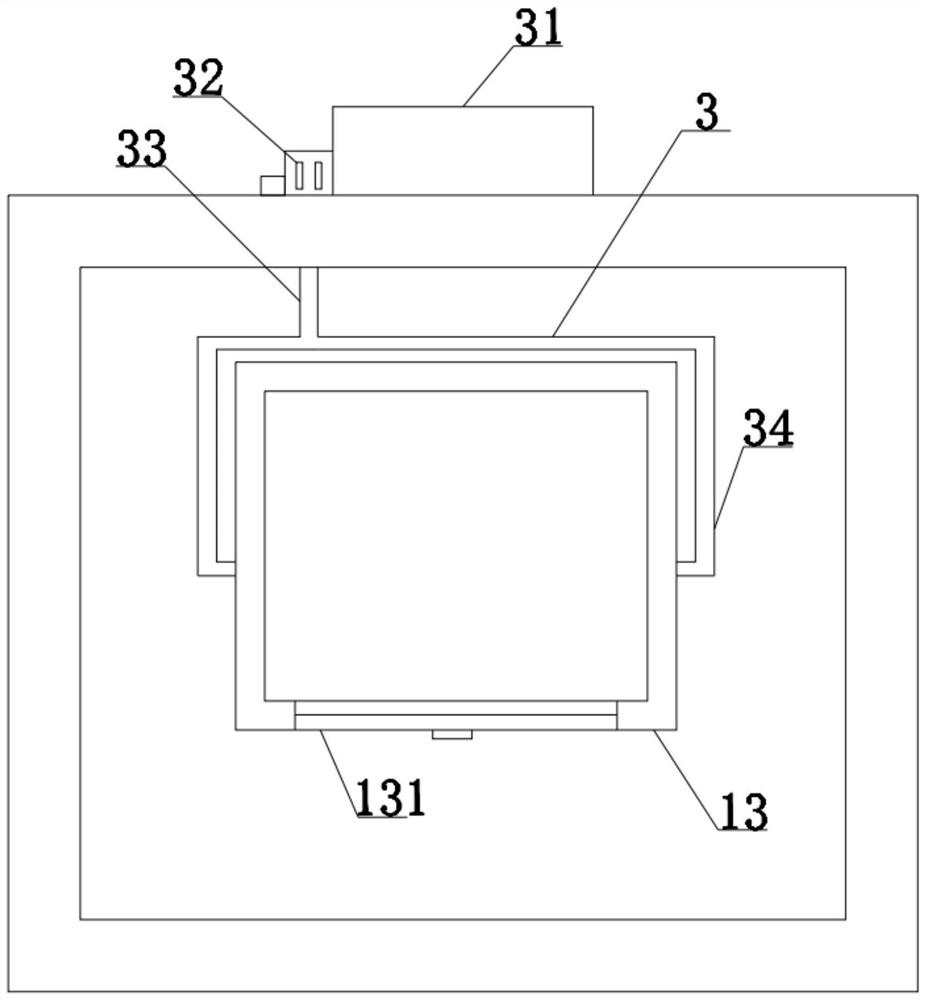

[0042] refer to image 3 In this embodiment, on the basis of Embodiment 1, in order to achieve the purpose of flushing garbage, this embodiment has carried out an innovative design for the cleaning assembly 3. Specifically, the cleaning assembly 3 includes a water storage tank 31, and the water storage tank 31 is fixedly connected On the rear side of the casing 1, the back side of the casing 1 is located on the side of the water storage tank 31, and a water pump 32 is fixedly connected. A first water outlet pipe 33 is fixedly connected to the water pipe, and a second water outlet pipe 34 is fixedly connected to one side of the first water outlet pipe 33 through the casing 1 . One end of the water pipe 34 is fixedly connected with a spray head 35, the spray head 35 is installed obliquely inside the housing 1, and the inner side of the spray head 35 is fixedly connected with a blocking net 36; The cleaning liquid is pumped into the first water outlet pipe 33, and flows to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com