Method for preparing 3-fluorobenzotrifluoride based on diazotization of dinitrogen trioxide

A technology of dinitrogen trioxide and fluorobenzotrifluoride, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, disproportionation separation/purification of halogenated hydrocarbons, etc., can solve problems such as long reaction routes, environmental pollution, and complicated processes, Achieve the effect of high production efficiency, energy saving and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

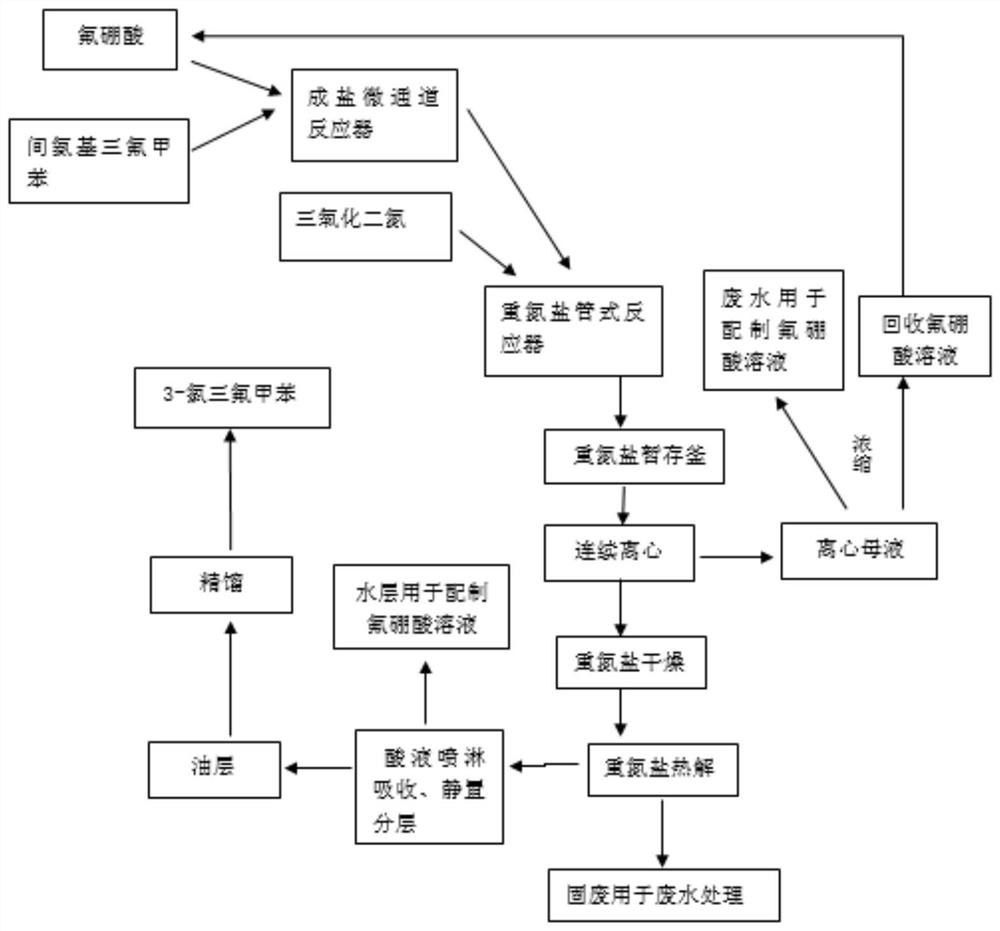

Image

Examples

Embodiment 1

[0027] (1) be that the fluoroboric acid solution of 25% by mass concentration and m-amino trifluorotoluene are pumped into the salt-forming microchannel reactor with the flow velocity of 9g / min, 1.5g / min respectively and carry out the salt-forming reaction at 15 ℃, After the salt is formed, it enters the diazonium salt tubular reactor;

[0028] (2) Introduce dinitrogen trioxide into the diazonium salt tubular reactor at a flow rate of 0.35g / min and carry out the diazotization reaction at -5°C, and the diazonium salt solution and the acid solution generated by the reaction enter the diazonium salt solution and the acid solution. The nitrogen salt is temporarily stored in the kettle, and subjected to continuous centrifugal treatment, the diazonium salt obtained by centrifugation is dried, and the dried diazonium salt is subjected to thermal decomposition treatment at 600 ° C, and the thermal decomposition rate is controlled to 2g / min; The mother liquor is concentrated, the mass ...

Embodiment 2

[0031] (1) be that the fluoroboric acid solution of 25% by mass concentration and m-amino trifluorotoluene are pumped into the salt-forming microchannel reactor with the flow velocity of 10g / min, 1.55g / min respectively and carry out the salt-forming reaction at 10 DEG C, After the salt is formed, it enters the diazonium salt tubular reactor;

[0032] (2) Introduce dinitrogen trioxide into the diazonium salt tubular reactor at a flow rate of 0.4 g / min and carry out the diazotization reaction at -5°C, and the diazonium salt solution and the acid solution generated by the reaction enter the diazonium salt solution and the acid solution. The nitrogen salt is temporarily stored in the kettle, and subjected to continuous centrifugal treatment, the diazonium salt obtained by centrifugation is dried, and the dried diazonium salt is subjected to thermal decomposition treatment at 700 ° C, and the thermal decomposition rate is controlled to 3g / min; The mother liquor is concentrated, the...

Embodiment 3

[0035] (1) be that the fluoroboric acid solution of 25% by mass concentration and m-amino trifluorotoluene are pumped into the salt-forming microchannel reactor with the flow velocity of 10g / min, 1.65g / min respectively and carry out the salt-forming reaction at 10 ℃, After the salt is formed, it enters the diazonium salt tubular reactor;

[0036] (2) Introduce dinitrogen trioxide into the diazonium salt tubular reactor at a flow rate of 0.5 g / min and carry out the diazotization reaction at -5°C, and the diazonium salt solution and the acid solution generated by the reaction enter the diazonium salt solution and the acid solution. The nitrogen salt is temporarily stored in the kettle, and subjected to continuous centrifugal treatment, the diazonium salt obtained by centrifugation is dried, and the dried diazonium salt is subjected to thermal decomposition treatment at 650 ° C, and the thermal decomposition rate is controlled to 2-3 g / min; centrifugal treatment The rear mother l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com