High-precision weld shape prediction method suitable for myriawatt laser welding

A technology of laser welding and prediction method, which is applied in the direction of instruments, complex mathematical operations, design optimization/simulation, etc., can solve the problem of low prediction accuracy of weld shape, and achieve high pressure calculation accuracy, good physical conservation, and stable calculation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and embodiments.

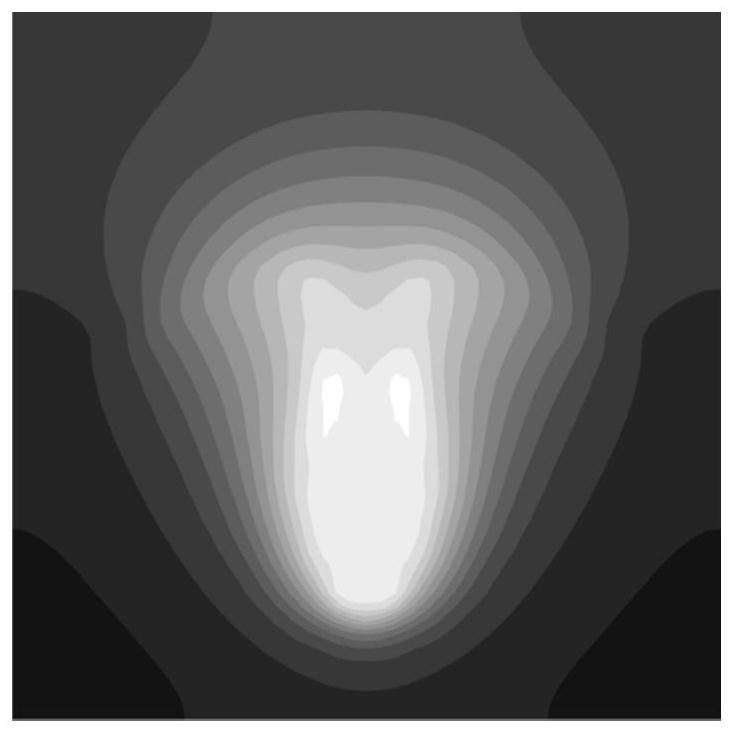

[0042] Aiming at the problem that the existing welding seam morphology prediction method cannot consider the coupling behavior of the molten pool and the plume, which leads to the low prediction accuracy of the 10,000-watt laser welding seam morphology, the present invention adopts the pressure-based compressible two-phase flow numerical calculation method to solve the problem. The coupling behavior of molten pool and plume can realize high-precision prediction of weld seam morphology of 10,000-watt laser welding.

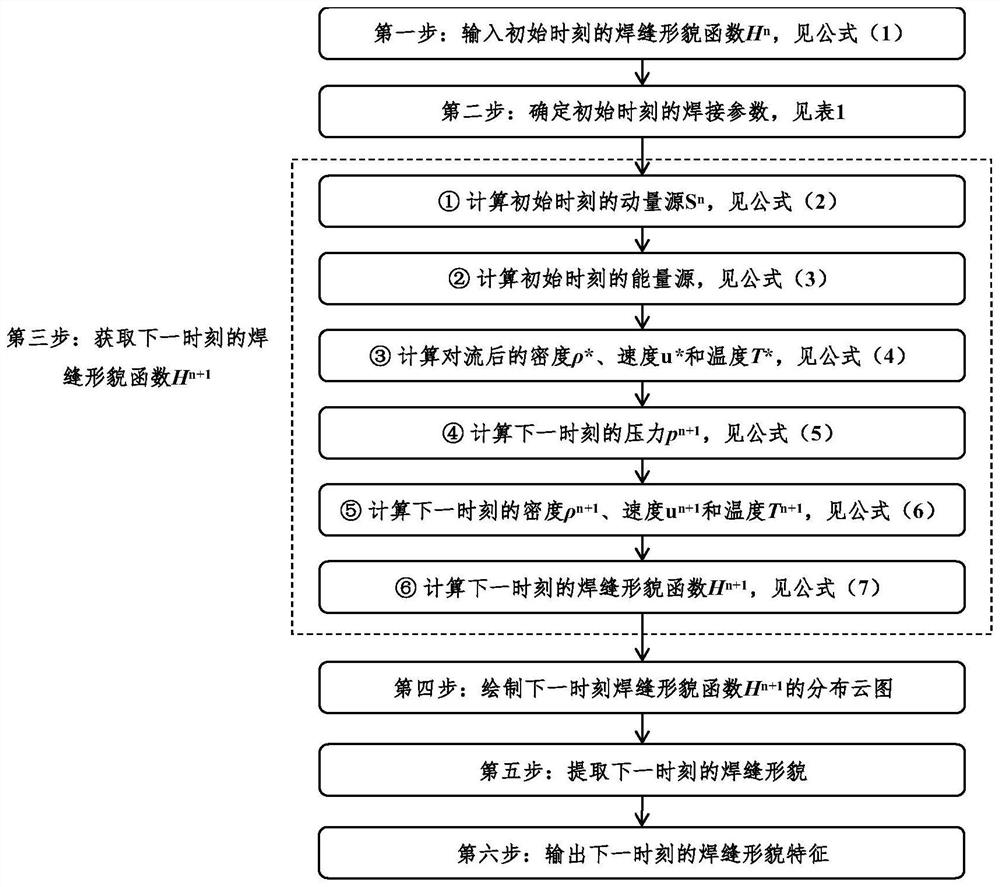

[0043] combine figure 1 , a method for predicting high-precision weld seam morphology suitable for 10,000-watt laser welding according to the present invention, comprising the following steps:

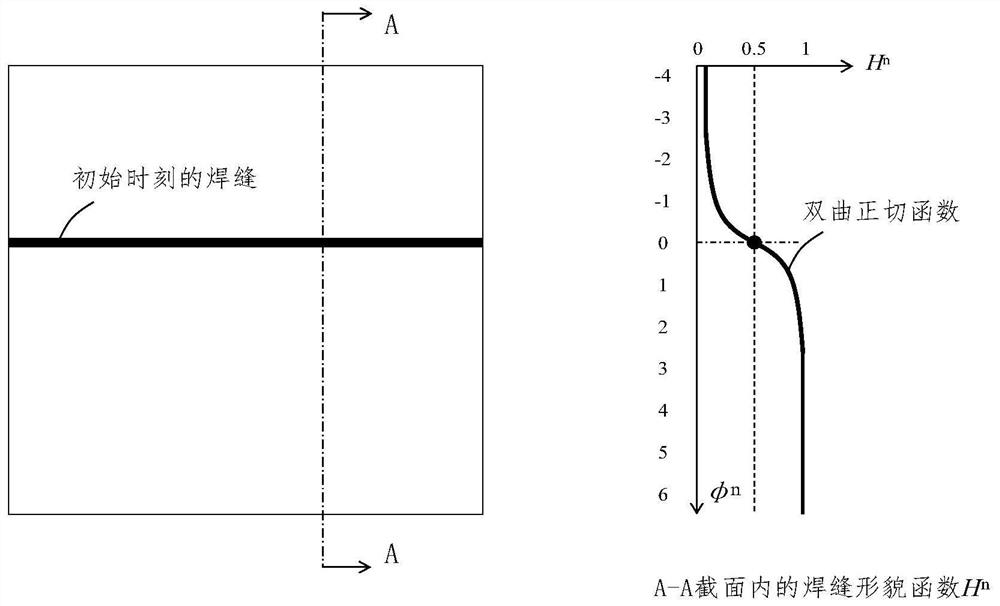

[0044] Step 1: Input the weld profile function at the initial moment

[0045] The present invention uses the hyperbolic tangent function to represen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com