UV aluminum wire enameled wire production system

A production system and enameled wire technology, applied in the field of enameled wire, can solve the problems of affecting the quality of finished products and the cooling effect is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

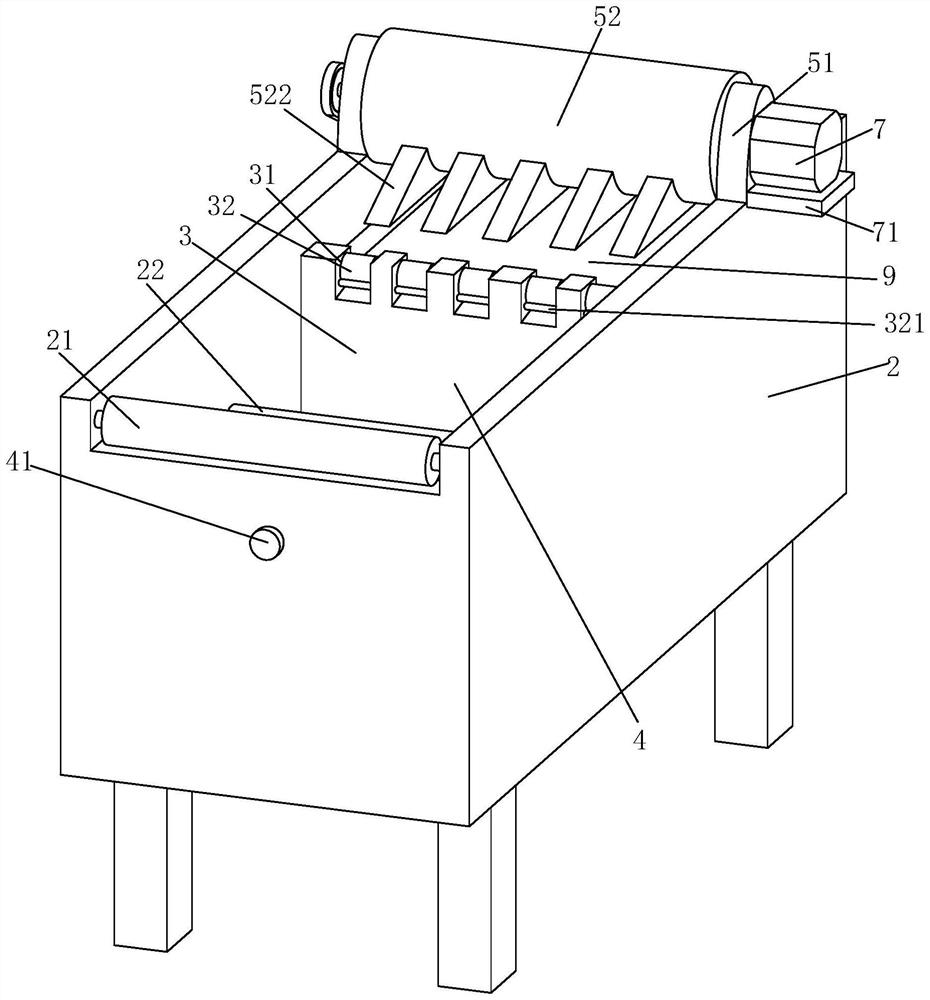

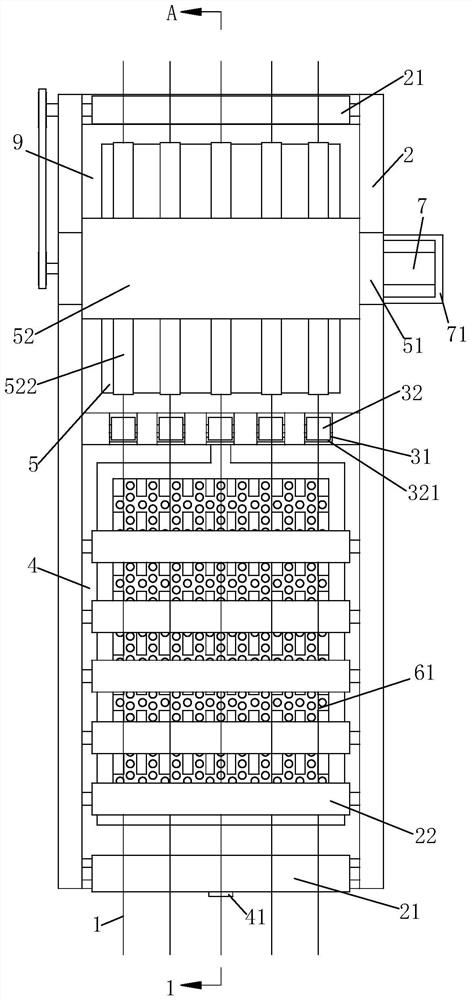

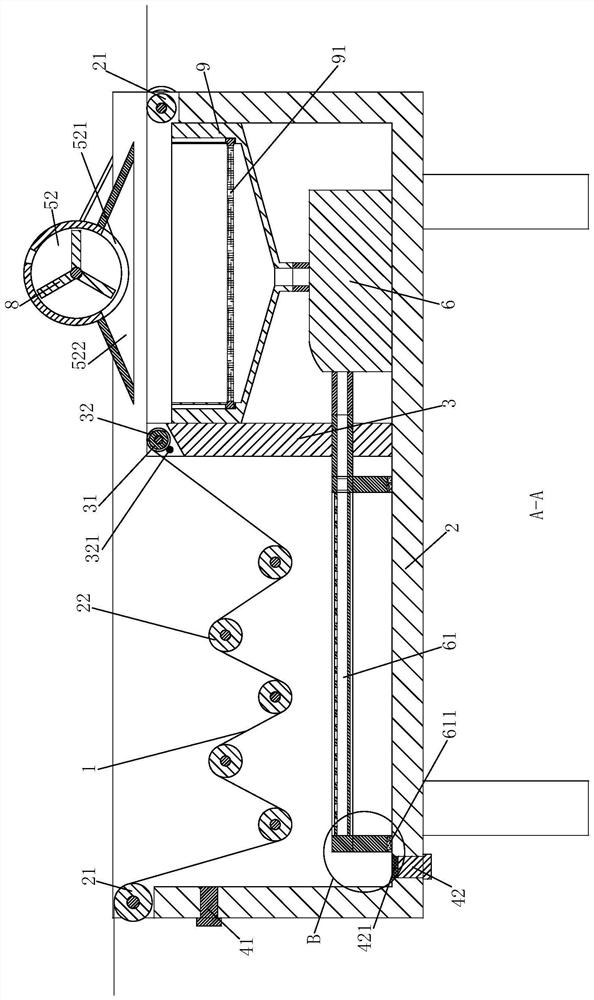

[0046] As a specific embodiment of the present invention, the heat dissipation assembly includes:

[0047] The partition plate 3 is located at the rear of the last pressing roller 22 inside the tank body 2, and is fixedly connected with the two side walls of the tank body 2;

[0048] The tank body 2 is divided into a heat dissipation tank 4 and a dehumidification tank 5 in turn with the partition plate 3 as the boundary;

[0049] A fixed pulley 31 is connected to the corresponding position of the upper end wall of the partition plate 3 and the aluminum wire enameled wire 1;

[0050] The blower 6 is installed on the inner surface of the lower end of the dehumidification tank 5, and the air outlet is facing the partition plate 3, and the air inlet is facing the top of the tank body 2;

[0051] The air exhaust frame 61 is located at the bottom of the heat dissipation slot 4, and is provided with a cavity inside, and one end of the air inlet pipe is connected to the air outlet of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap