Copper piece alignment device for power strip processing

A technology for aligning devices and copper parts, applied in the assembly/disassembly of contact parts, electrical components, conveyor objects, etc., can solve problems affecting connection stability, etc., and achieve the effect of complete process and accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

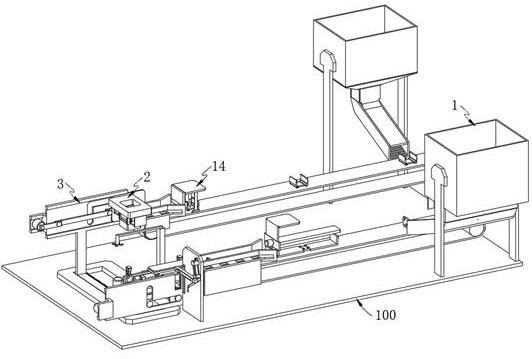

[0072] like Figure 1-2 As shown, an alignment device for copper parts for socket and row processing includes a workbench 100, and further includes:

[0073] A blanking unit 1, the blanking unit 1 for sequentially transporting the copper sheets downward is arranged at one end of the workbench 100;

[0074] The alignment unit 2 is used to connect the alignment unit 2 for aligning the position of the transmitted copper sheet with the blanking unit 1, and is located in the middle of the workbench 100;

[0075] The alignment unit 2 includes:

[0076] The alignment column assembly 21, which is used for locating the position of the copper sheet with the protrusions, is connected to the blanking unit 1, and is arranged on one side of the workbench 100; and

[0077] The hole alignment assembly 22, which is used for locating the position of the copper sheet with blind holes, is connected to the blanking unit 1, and is arranged on the other side of the workbench 100;

[0078] The doc...

Embodiment 2

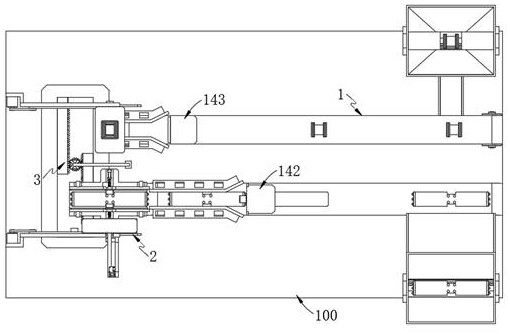

[0146] like Figure 3-4 , Image 6 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0147] further, as Figure 3-4 As shown, the first screening unit 142 includes:

[0148] a first mounting seat 1421, the first mounting seat 1421 is arranged on the workbench 100;

[0149] an intercepting plate 1422, the intercepting plate 1422 is arranged on the first installation;

[0150] an adsorption plate 1423, the adsorption plate 1423 is connected with the intercepting plate 1422, and is arranged on one side of the first mounting seat 1421;

[0151] When the intercepting plate 1422 blocks the copper sheet from falling into the conveyor belt 13 from the lower hopper 11, the side is placed on the conveyor...

Embodiment 3

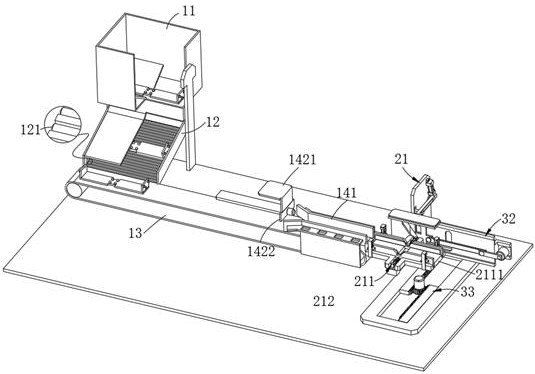

[0162] like Figure 4 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the first embodiment and the first embodiment is:

[0163] The first fixing mechanism 212 includes:

[0164] a first clamping plate 2121, the first clamping plate 2121 is elastically arranged on both sides of the first receiving plate 2111;

[0165] a first pressing plate 2122, the first pressing plate 2122 is slidably connected to the first clamping plate 2121;

[0166] The pushing device pushes forward, and drives the elastic piece elastically connected between the first clamping plate 2121 and the pushing device to squeeze the copper sheet. The outer part of the first clamping plate 2121 after the position is fixed is provided with a casing, which is pushed by the pushing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com