Hot waste gas as-fired coal preheating and active coke regenerating device

A technology of activated coke regeneration and hot waste gas, which is applied in the direction of climate sustainability, coke oven, energy input, etc., can solve the problems of affecting the processing of furnace coal and the inability to heat uniformly of furnace coal, and achieve uniform heating, convenient use, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

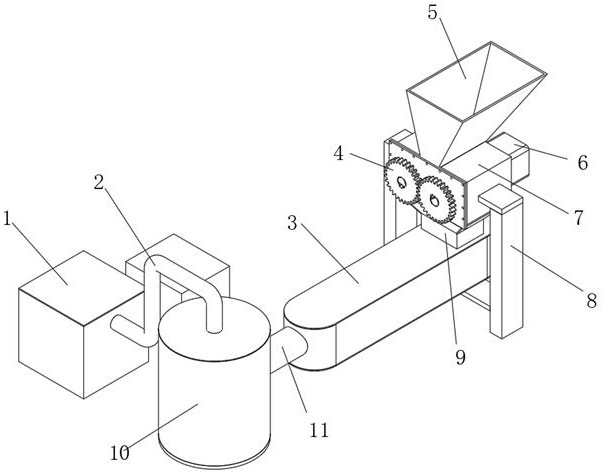

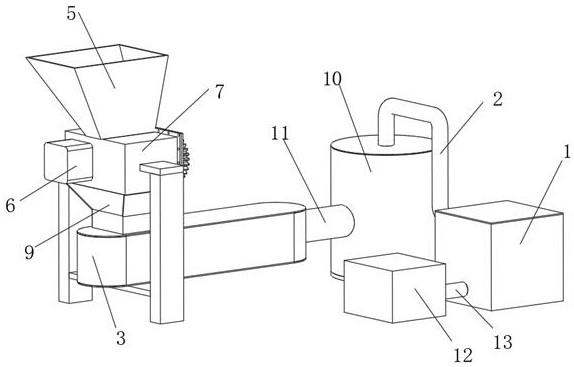

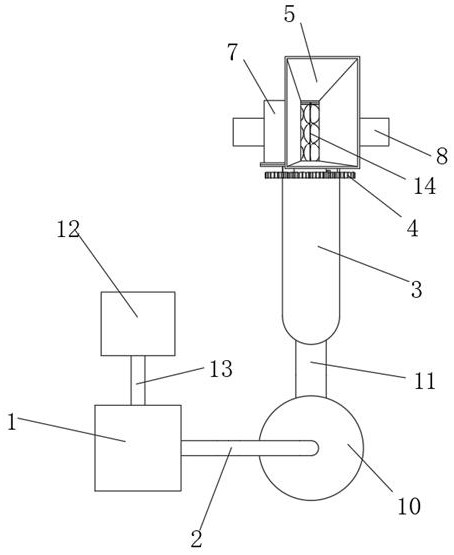

[0022] see Figure 1-Figure 5 , the present invention provides the following technical solutions: a hot waste gas into the furnace coal preheating and active coke regeneration device, including a crusher 7, the top of the crusher 7 is provided with a feeding hopper 5, the interior of the crusher 7 is rotated and provided with a roller 14, the crusher 7 7. A first motor 6 that can rotate the roller 14 is installed on one side, a vibrator 3 is arranged below the crusher 7, a vibrating plate 17 is moved inside the vibrator 3, and the bottom of the vibrating plate 17 has an axial distribution along the vibrating plate 17. The provided spring 16, the bottom of the vibrating plate 17 is installed with a vibrating motor 15 that can make the vibrating plate 17 vibrate. In this embodiment, when in use, turn on and open the power supply components of each part of the device, and then put the furnace coal from the feeding hopper 5. The two rollers 14 inside the crusher 7 are driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com