Device and method for testing integrity of cement sheath under simulated prestress effect

A testing device and technology of cement sheath, which are used in surveying, earthmoving, wellbore/well components, etc., can solve the problems of unclear influence mechanism, difficulty in testing shear bond strength, and lack of cement sheath integrity testing. , to achieve the effect of simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

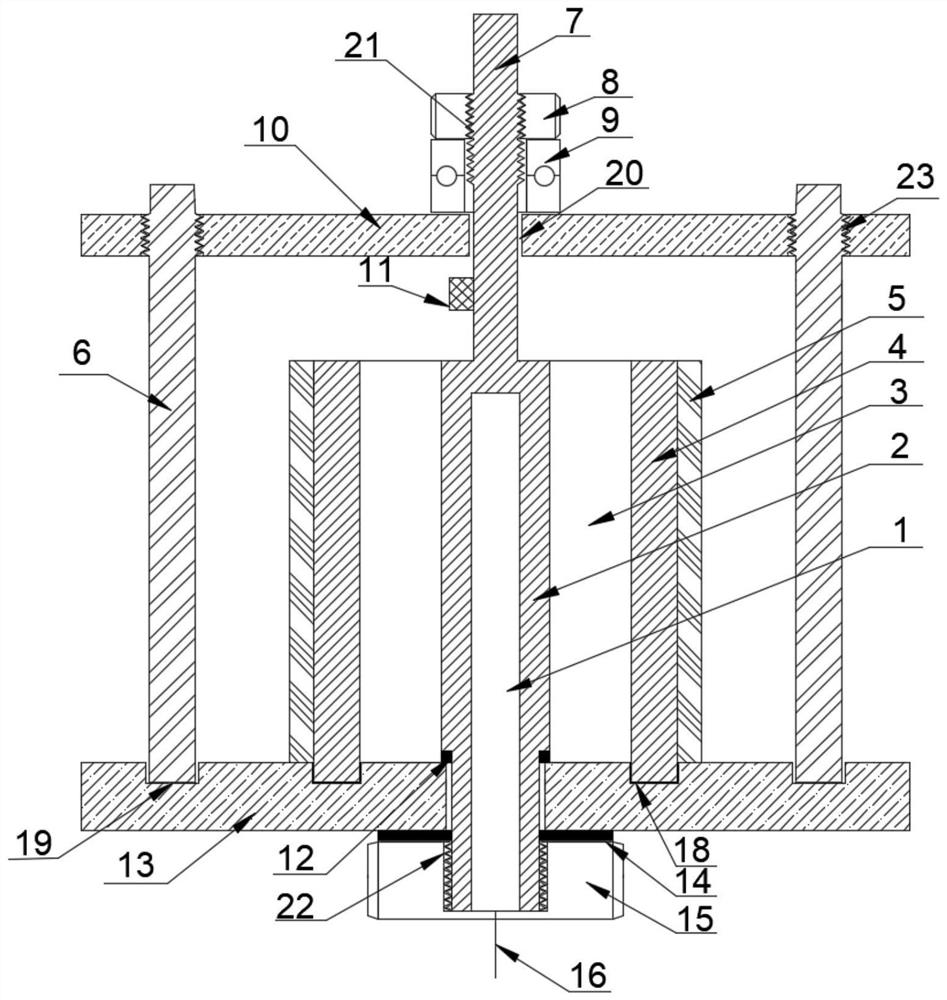

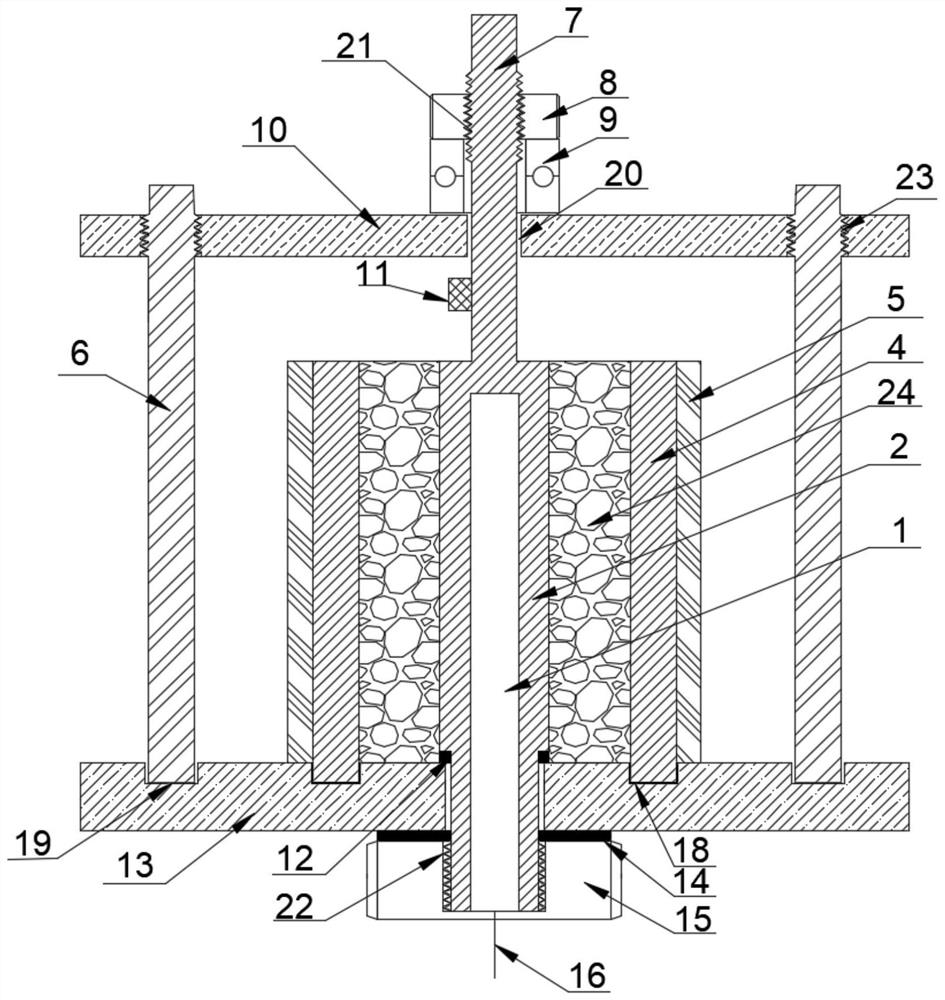

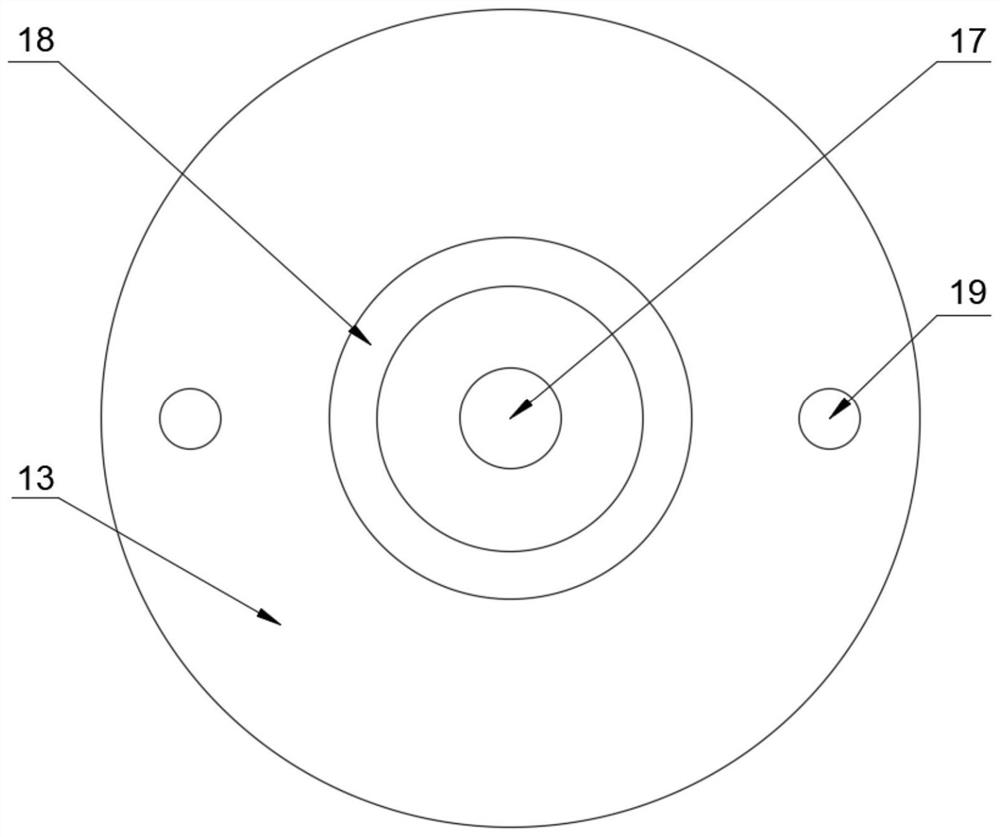

[0021] The present invention provides a cement sheath integrity testing device and method under simulated prestress, characterized in that the device comprises a pressure-bearing chamber 1, an inner blind pipe 2, an annulus 3, an outer casing 4, a heating jacket 5, a first Screw 6, second screw 7, first nut 8, booster bearing 9, square rod 10, stress sensor 11, rubber washer 12, circular plate 13, washer 14, second nut 15, pressure control system 16, first pass Hole 17 , annular groove 18 , circular groove 19 , second through hole 20 , first male thread 21 , second male thread 22 , third male thread 23 , cement ring 24 ; wherein the circular plate 13 includes the first through hole 17 , the ring groove 18 and the circular groove 19 are used to fix the inner blind pipe 2, the outer sleeve 4 and the first screw 6 respectively; the inner blind pipe 2 welded with the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com