Medical degradable liquid-absorbing leakage-proof protection pad and manufacturing method thereof

A manufacturing method and technology for pads, which are applied in the fields of absorbent pads, applications, medical science, etc., can solve the problems of liquid exudation and weak adhesion, etc., so as to improve the reliability of use, improve the anti-leakage ability, and connect firmly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

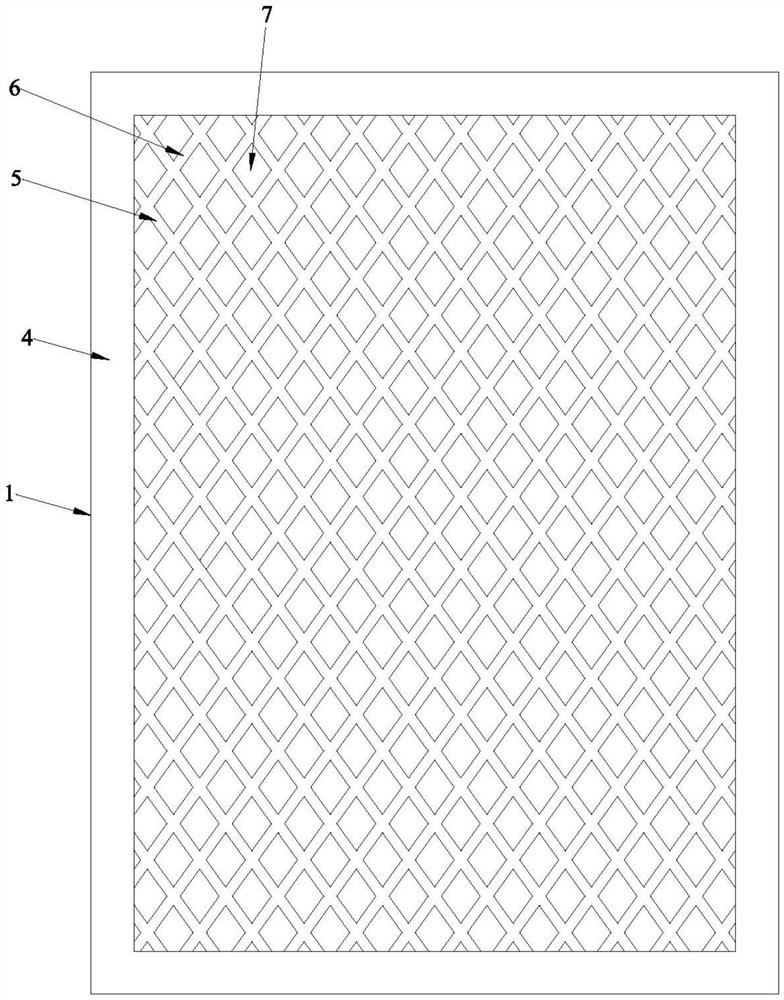

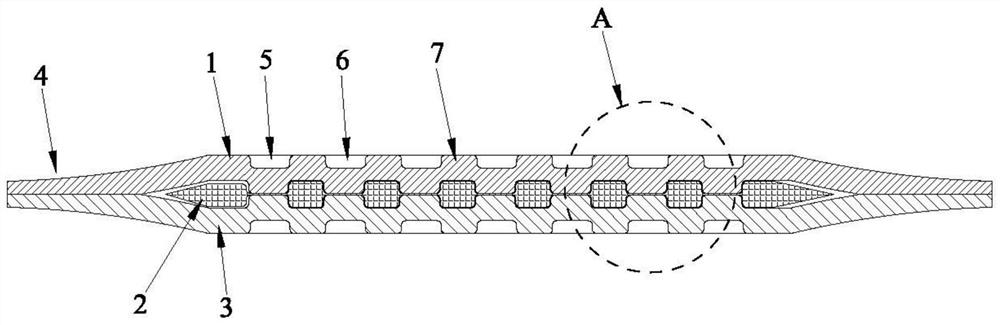

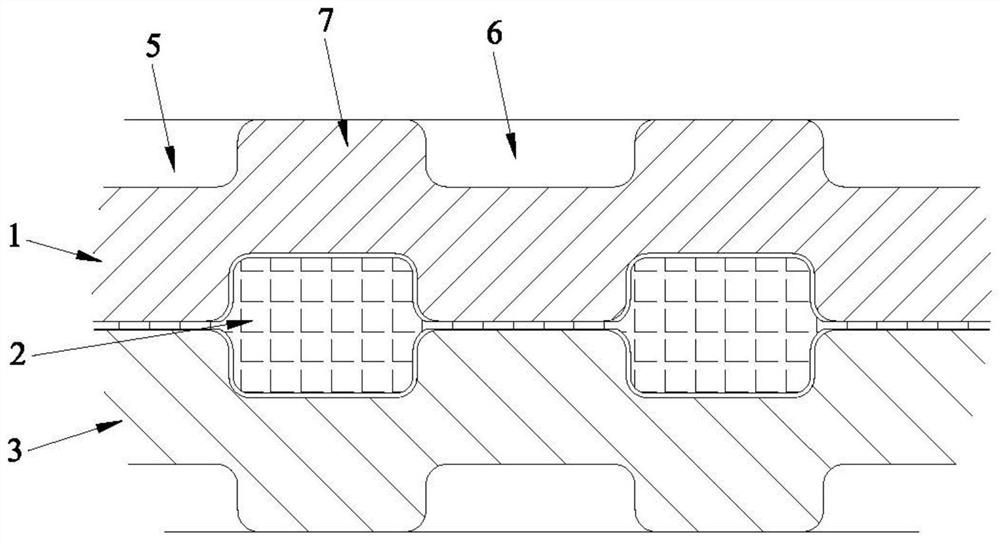

[0035] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of a preferred embodiment of the present invention, which is a medical degradable liquid-absorbing and leak-proof pad, including a water-permeable layer 1 , a water-absorbing layer 2 and a waterproof layer 3 .

[0036] Before explaining the embodiments of the present application in detail, the application scenarios of the embodiments of the present application are described first.

[0037] There are usually two ways for traditional medical pads. The first is to laminate the water permeable layer, the water absorption layer and the waterproof layer, and glue each two layers to bond them together. The pads manufactured by this production process, Due to the coating of glue, users who have allergic reactions to chemicals cannot use it, and a large amount of glue is used, which is not environmentally friendly; Press-melt with the edge of the waterproof layer to connect the edges of the water-pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com