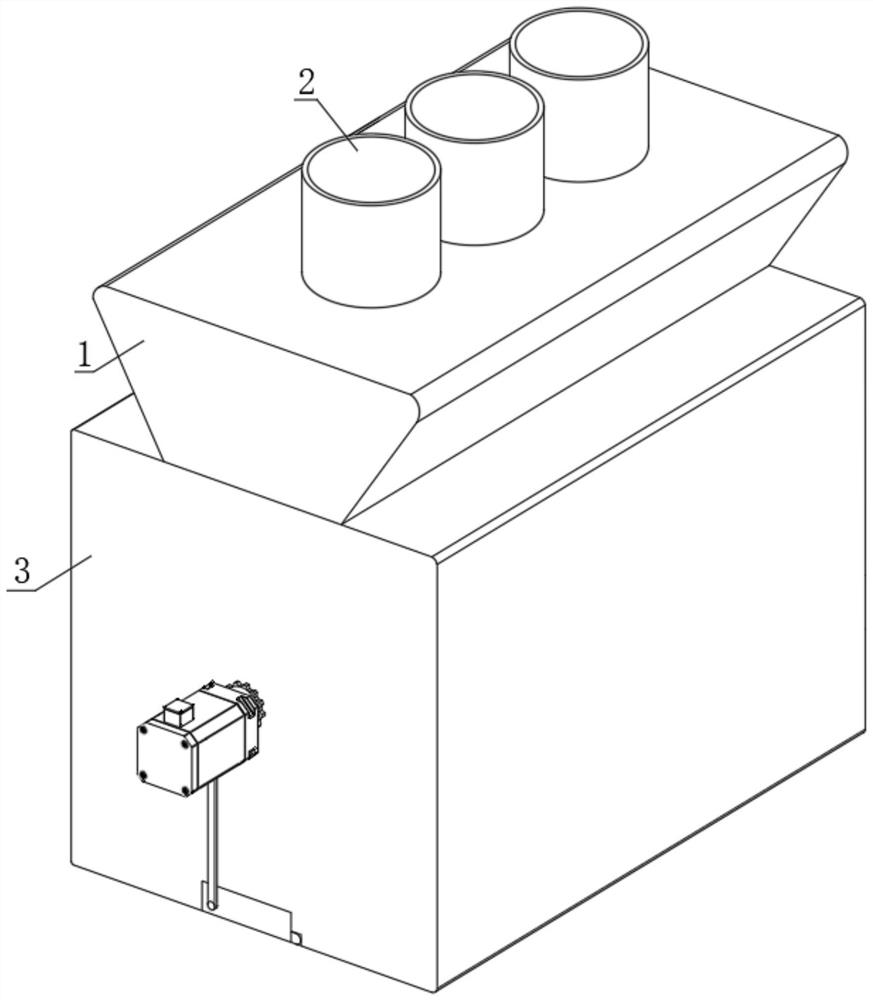

Device and method for preparing bi-component modified silicone sealant for prefabricated building

A silicone sealant, two-component modification technology, applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problem of high adhesion, large retention, and difficult discharge Clean and other problems, to achieve the effect of improving the mixing effect and improving the mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0060] Another technical solution proposed by the present invention: providing an implementation method of a two-component modified silicone sealant preparation device for prefabricated buildings, comprising the following steps:

[0061] Step 1: push the traction member 54, so that the driving gear 414 and the driven gear 51 are staggered, and the two cannot be driven, and then the secondary mixing mechanism 4 is activated;

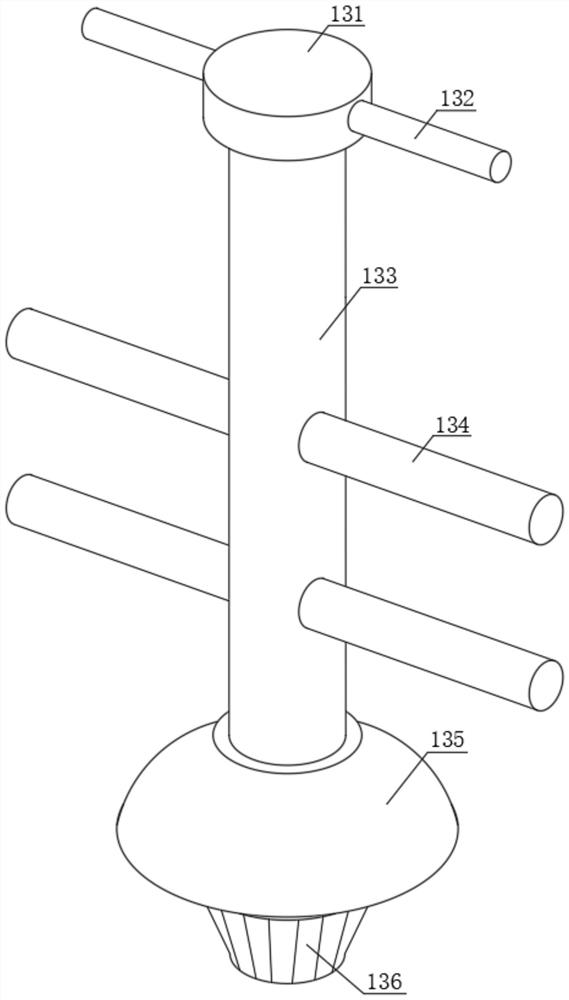

[0062] Step 2: Squeeze the mixing assembly 41, and then drive the first transmission belt 42 to rotate, the first transmission belt 42 further drives the transmission rod 44 to rotate, the transmission rod 44 further drives the middle active conical tooth 45 to rotate, and the active conical tooth 45 further drives the slave The movable bevel gear 136 rotates, and the driven bevel gear 136 then drives the auxiliary stirring rod 134 to rotate. At this time, the auxiliary stirring rod 134 will transport a variety of raw materials for preliminary mixing. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap