Amino silicone oil emulsification reactor

A technology of amino silicone oil and reactor, which is applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc. It can solve the problem of multi-time, reduce the working efficiency of the reactor, occupy the staff, etc. problem, to achieve the effect of increasing work efficiency, saving working time and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

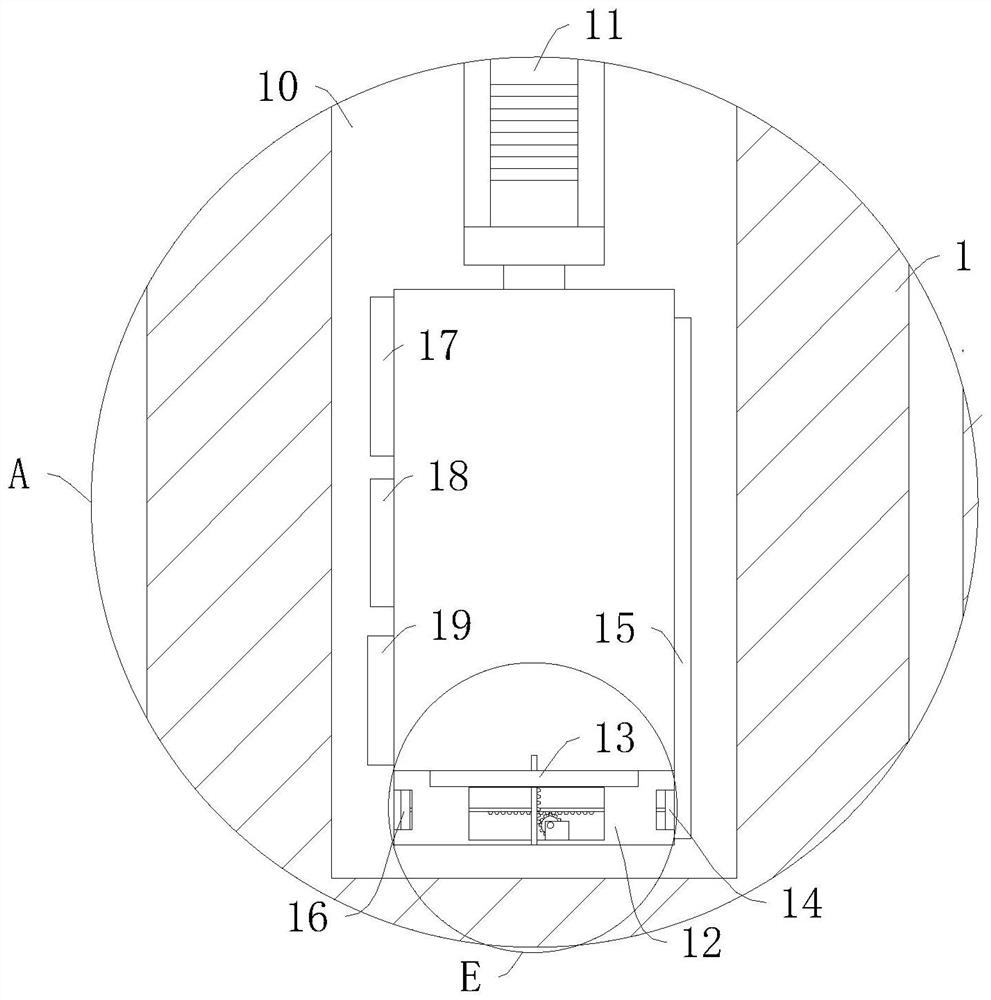

[0066] As an embodiment of the present invention, refer to Image 6 , the control mechanism includes a control shell 23 fixedly installed inside the reactor main body 1, a first moving plate 24 is movably installed inside the control shell 23, a push rod 25 is fixedly installed on one side of the first moving plate 24, and the push rod 25 Extending into the component slot, the first moving plate 24 is elastically connected with the inside of the control housing 23 , a conductive column 26 is fixedly installed on the side of the first moving plate 24 away from the push rod 25 , and the inside of the control housing 23 is movably installed with a conductive column 26 . The two power transmission boards 30 cooperate with the conductive pillars 26 and are electrically connected to the power supply and the energization spring 36 respectively. The inside of the control housing 23 is fixedly installed with a moving component for controlling the movement of the power transmission board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com