Multi-frequency megasonic coupling wafer cleaning equipment and multi-frequency spraying device

A technology for cleaning equipment and spraying devices, applied in cleaning methods and utensils, cleaning methods using liquids, sustainable manufacturing/processing, etc., can solve the problems of insufficient impact energy of peeling particles, poor cleaning effect, etc., and achieve high cleaning Efficiency and Particle Removal Rate, Yield Improvement, Effect of High Process Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

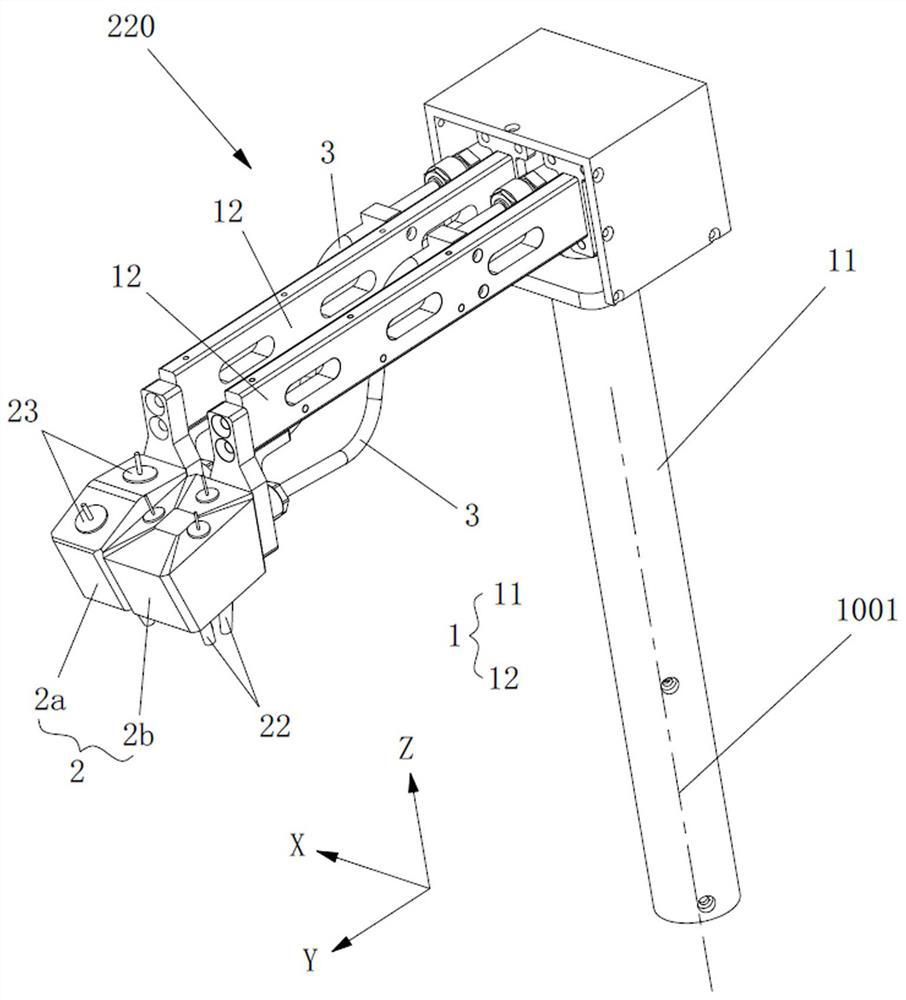

[0042] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

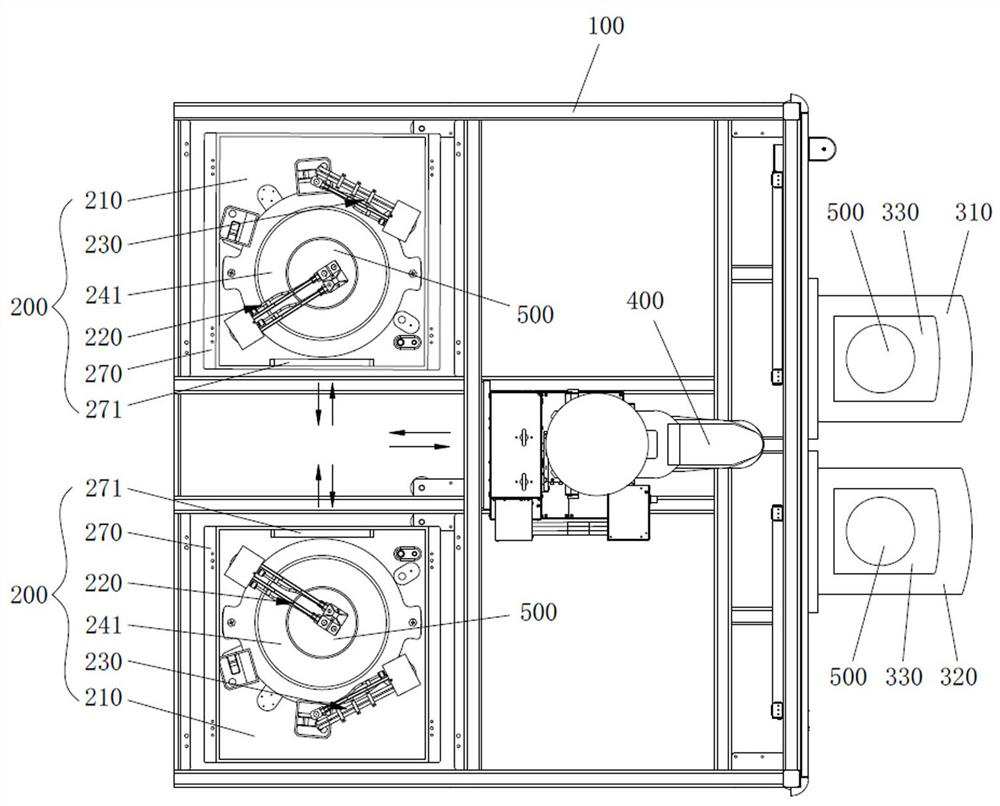

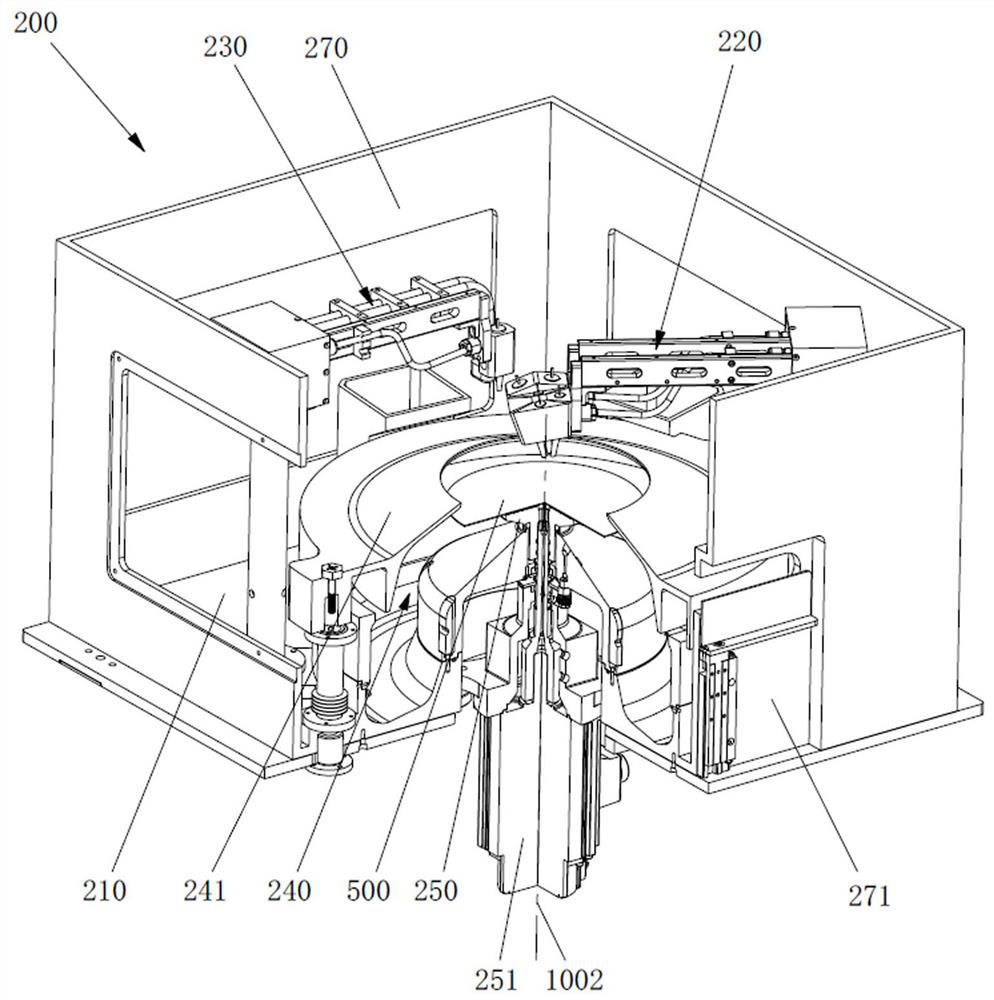

[0043] see figure 1 As shown, a multi-frequency megasonic wave coupled wafer cleaning equipment is used for successively cleaning a single wafer 500 in a semiconductor wet process, and is especially suitable for removing the contamination of tiny particles adhering to the surface of the wafer 500 by the megasonic wave technology thing. The cleaning equipment includes a workshop 100 , a first loading table 310 , a second loading stage 320 located on one side of the workshop 100 , a cleaning module 200 and a transmission device 400 and the like located in the workshop 100 .

[0044] In this embodiment, two groups of cleaning modules 200 capable of cleaning the wafers 500 are provided in the workshop 100 at the same time, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com