Single-edge diamond cutting tool with adjustable outer diameter and replaceable cutting edge

A technology of diamond tools and cutting tools, which is applied to tools for lathes, turning equipment, manufacturing tools, etc., can solve the problems of random distribution, low surface quality of workpieces, easy falling off of abrasive grains, etc., and achieves good processing efficiency. Easy replacement and small cutting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

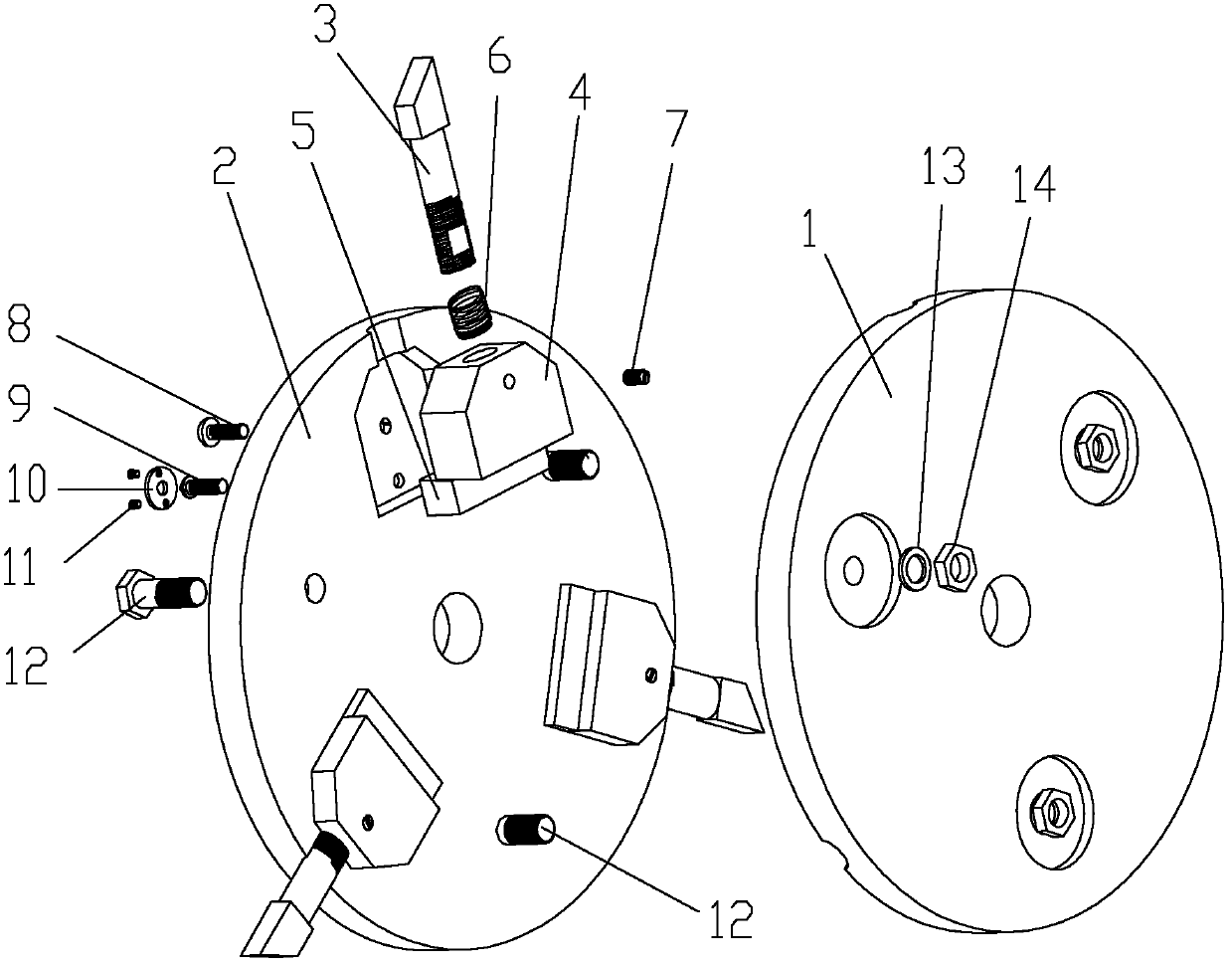

[0013] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

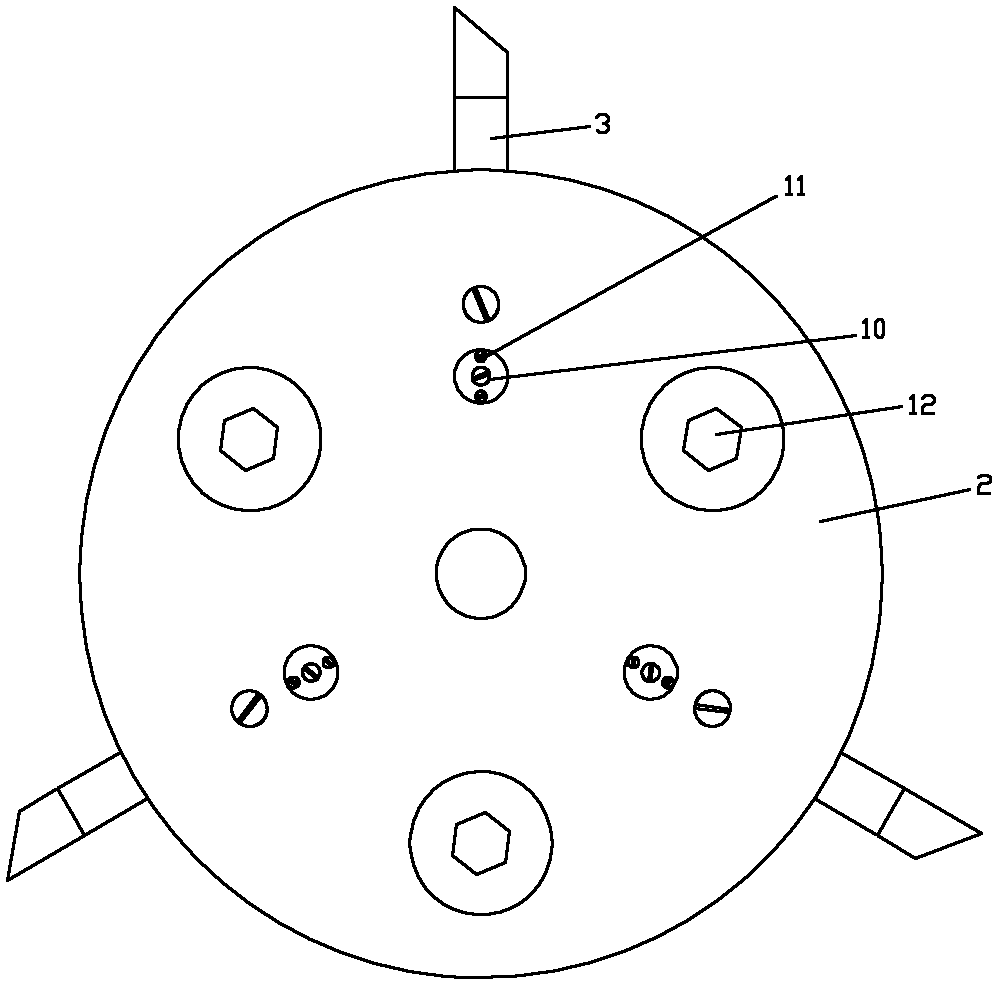

[0014] like figure 1 and 2 As shown, the embodiment of the present invention is provided with a front tool rest body 1, a rear tool rest body 2, a single-edged diamond cutter 3, an inverted trapezoidal tool holder 4, an adjustment pad 5, a spring 6, a small set screw 7, a large set screw Screw 8, block adjusting screw rod 9, retaining ring 10, screw 11, fixing bolt 12, washer 13 and nut 14; the single-edged diamond cutter 3 is threadedly connected with the inverted trapezoidal cutter holder 4 and fixed by the small set screw 7; A spring 6 is arranged between the top of the inverted trapezoidal tool holder 4 and the groove of the rear tool rest body 2; the pad adjusting screw 9 is fixed on the rear tool rest body 2 by a retaining ring 10 and a screw 11, and the pad The end of the block adjusting screw 9 is connected with the knife seat adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com