Thin microcapsule magnetic flowing display panel and its using method

A technology of microcapsules and display panels, applied in the directions of microcapsule preparations, microsphere preparation, static indicators, etc., can solve problems such as obstacles in use and lack of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

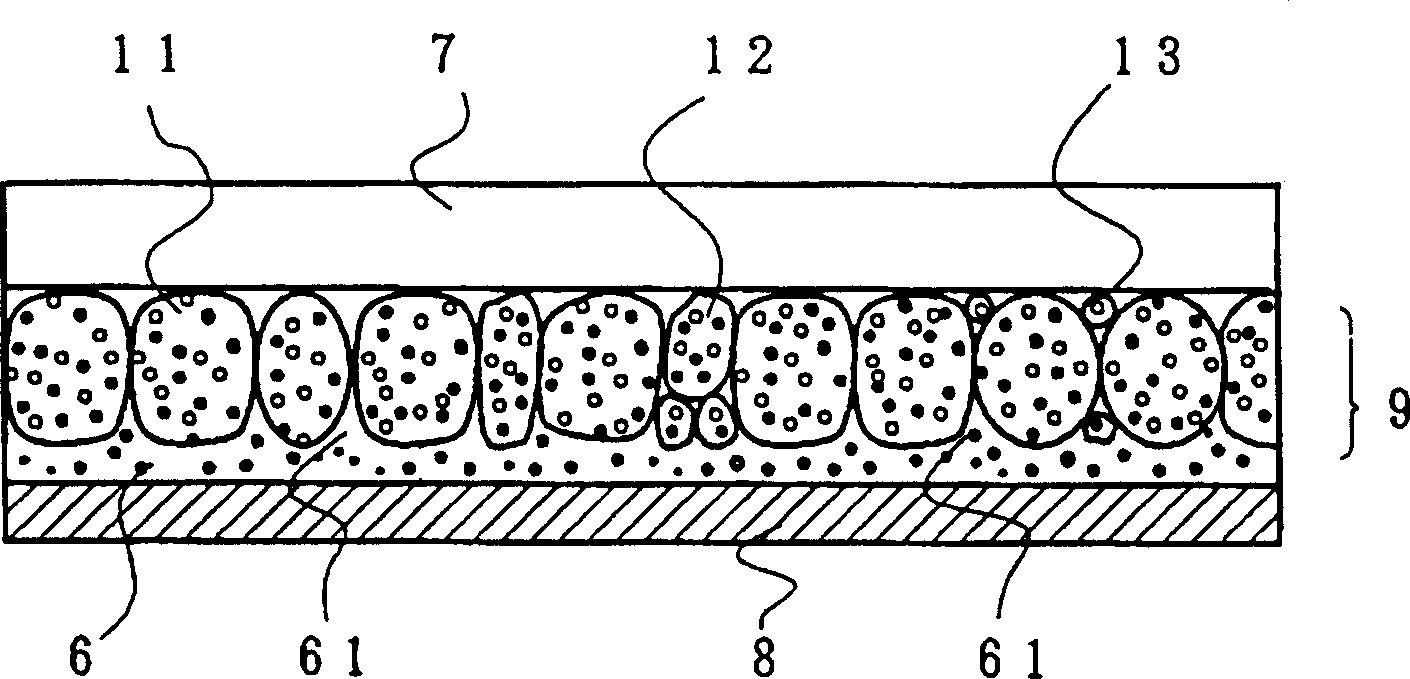

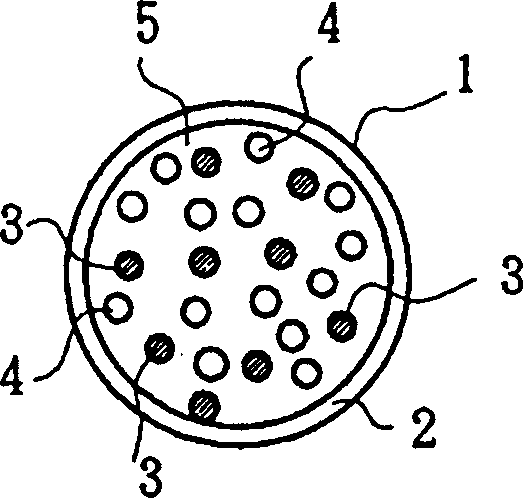

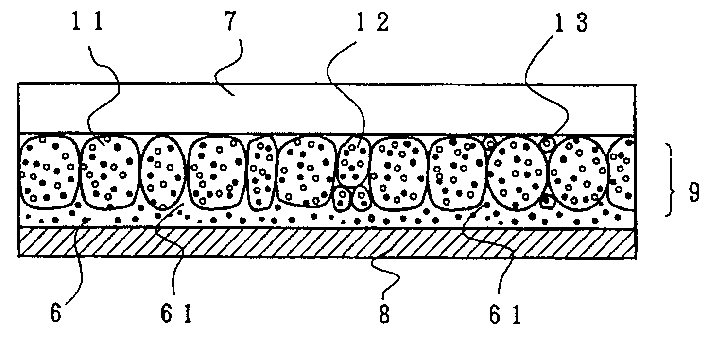

[0073] figure 1 is a sectional view of the microcapsule magnetic display panel of the present invention, in addition, the microcapsule of the present invention has figure 2 The sectional view shown. figure 2 The microcapsule 1 shown in is formed by encapsulating magnetic particles 3 and non-magnetic particles 4 dispersed in a dispersant 5 in a gelatin coating 2 . Such microcapsules are produced as follows. As the magnetic particles 3, ferrite powder particles with an average particle size of 0.3 μm (trade name Talaus Kusi (Clocks) BL-50, a product manufactured by Titanium Industry Co., Ltd.) were pulverized to obtain 2% by weight and as For non-magnetic particles 4, 40% by weight of dibutyl phthalate as a high boiling point solvent was added to 11.6% by weight of white titanium oxide powder (trade name R-820, manufactured by Ishihara Sangyo Co., Ltd.) with an average particle diameter of 0.26 μm. To the mixed solvent after mixing 45% by weight of toluene as a low boiling ...

Embodiment 2

[0079] For the microcapsule magnetic display panel produced in Example 1, the type of erasing magnet was changed, and the erasing state was investigated. When using a one-sided multi-pole magnet for erasing work (moving on the surface where the characters are recorded), the writing can be erased, but streaks are generated on the surface of the board, and it cannot be erased in a uniform state. In addition, when erasing was performed using an erasing magnet with a surface magnetic flux density of 1100 Gauss, a dark surface was obtained, which was not very good. On the other hand, in the present invention, when erasing is performed using an erasing magnet having a surface magnetic flux density of 250 gauss, notes can be erased cleanly, and the surface is white and clean without unevenness. In addition, in this example, the magnet is moved on the character recording surface for erasing. In the present invention, of course, it is also possible to move the magnet inside the display...

Embodiment 3

[0081] According to the method of Example 1, respectively manufacture (1) microcapsules with an average particle diameter less than 10 μm; (2) microcapsules with an average particle diameter of 30 μm; (3) microcapsules with an average particle diameter of 100 μm; (4) with an average particle diameter of 150 μm microcapsules and (5) microcapsules with an average particle diameter of 250 μm, and further make a microcapsule magnetic display panel in the same manner as in Example 1, and observe the note state and the elimination state respectively. In (1) of the prior art, the entire surface is a blackened notebook without contrast. In addition, the elimination state is also dark. In (5) of the present invention, since the elimination becomes slightly darker, a black-and-white contrast is formed, and there is no obstacle in practical use. Particularly preferred are (2) to (4) in the present invention, each of which has a good erasing state, is white, and has a large contrast with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com