Plastic warm air blower pressure chamber plate assembly

A technology for heaters and pressure chambers, applied in the superstructure sub-assemblies, heating/cooling equipment, vehicle parts, etc., can solve the problems of high maintenance cost of mold products, increased assembly complexity, high cost of sheet metal parts, and reduced The number of molds and inspection tools, the effect of improving the endurance and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

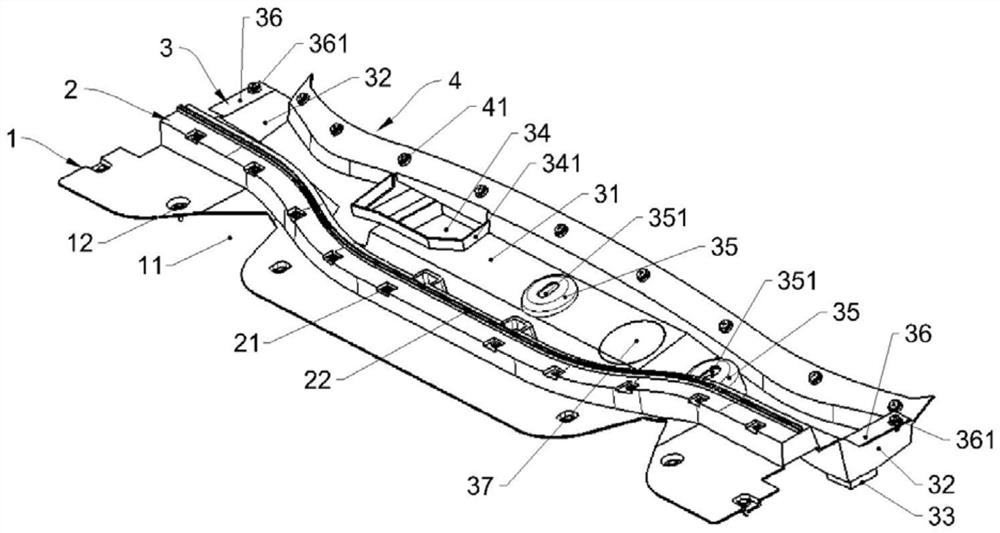

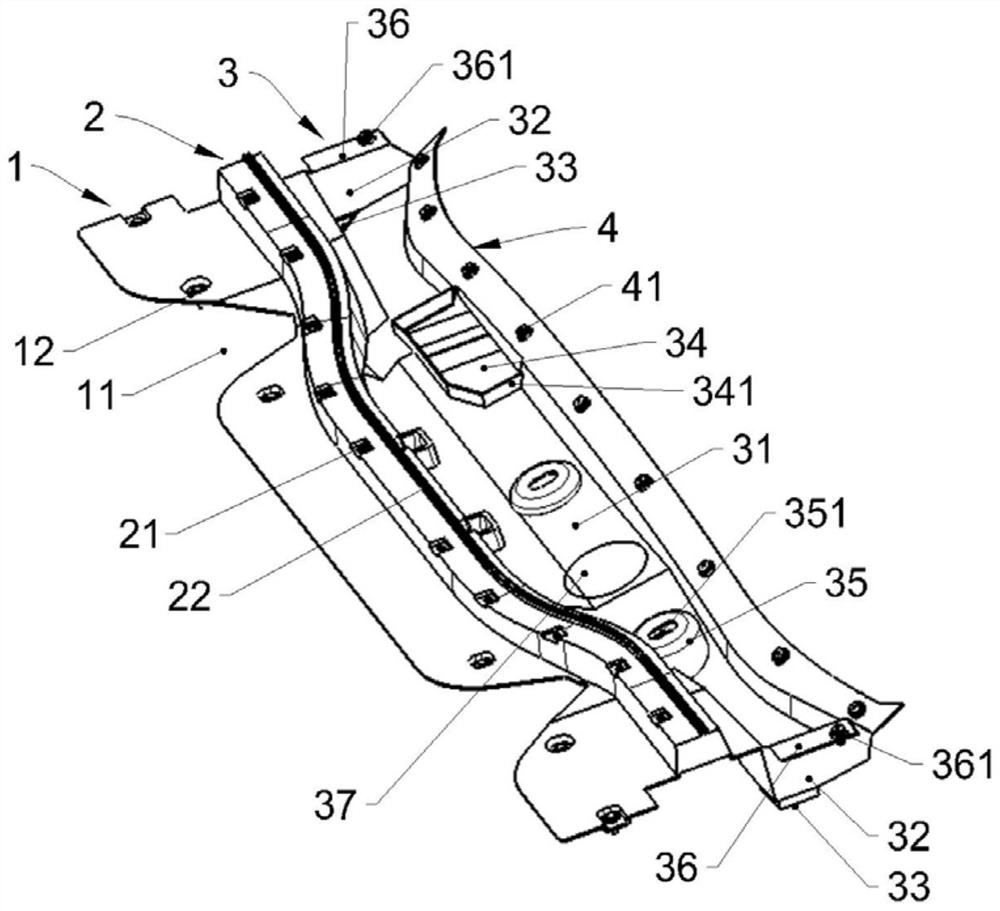

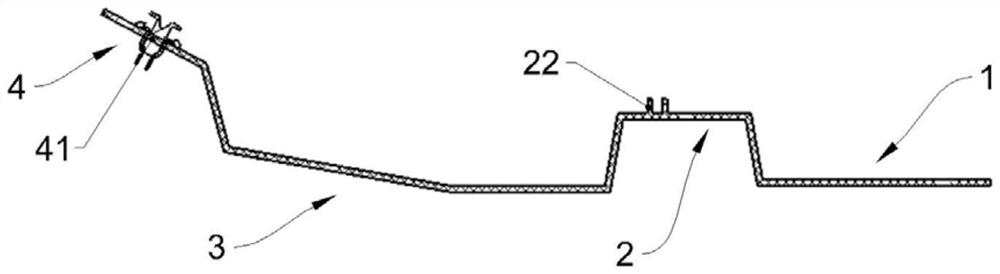

[0031] like Figure 1-Figure 4 As shown in the figure, a plastic heater pressure chamber plate assembly in this embodiment includes a front mounting plate 1, a front cover connecting seat 2, a flow groove 3 and a rear mounting plate 4, which are arranged in sequence from front to back. The front mounting plate 1 , The front cover connecting seat 2, the water tank 3 and the rear mounting plate 4 are all made of plastic, preferably PP+GF30 material, that is, glass fiber reinforced polypropylene; the water tank 3 includes a U-shaped groove main body 31 and two water baffles 32. The main body 31 of the U-shaped groove is recessed downward on the front mounting plate 1 and the front cover connecting seat 2. The two water blocking plates 32 are respectively arranged on the left and right ends of the main body 31 of the U-shaped groove, and the two water blocking plates 32 can be opposite to each other. The left and right ends of the U-shaped groove body 31 are blocked; the U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com