Scale inhibition method for boiler

A boiler and scale inhibitor technology, which is applied in the field of boiler scale inhibition to achieve the effects of equipment safety, convenient cleaning and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

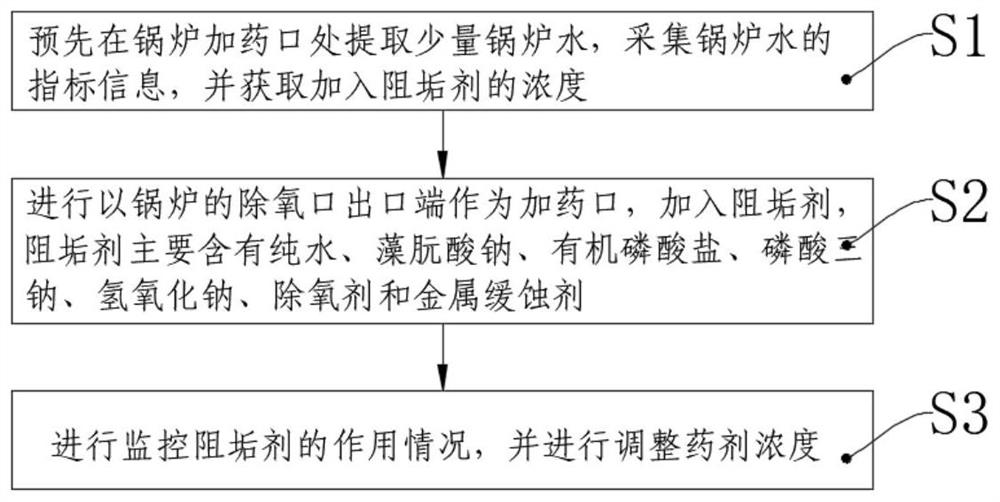

[0034] like figure 1 As shown, the scale inhibition method for a boiler according to an embodiment of the present invention includes the following steps:

[0035] Step S1, extract a small amount of boiler water at the boiler dosing port in advance, collect the index information of the boiler water, and obtain the concentration of the added scale inhibitor;

[0036] In step S2, the outlet of the deaerator port of the boiler is used as the dosing port, and the scale inhibitor is added, and the scale inhibitor mainly contains pure water, sodium alginate, organic phosphate, trisodium phosphate, sodium hydroxide, and oxygen scavenger. and metal corrosion inhibitors;

[0037] Step S3, monitoring the effect of the scale inhibitor, and adjusting the scale inhibitor concentration, including the following steps;

[0038] Step S301, collecting index information and scale inhibitor concentration information of boiler water in a period;

[0039] Step S302, based on the index information...

Embodiment 2

[0046] like figure 1 As shown, the scale inhibition method for a boiler according to an embodiment of the present invention includes the following steps:

[0047] Step S1, extract a small amount of boiler water at the boiler dosing port in advance, collect the index information of the boiler water, and obtain the concentration of the added scale inhibitor;

[0048] In step S2, the outlet of the deaerator port of the boiler is used as the dosing port, and the scale inhibitor is added, and the scale inhibitor mainly contains pure water, sodium alginate, organic phosphate, trisodium phosphate, sodium hydroxide, and oxygen scavenger. and metal corrosion inhibitors;

[0049] Step S3, monitoring the effect of the scale inhibitor, and adjusting the scale inhibitor concentration, including the following steps;

[0050] Step S301, collecting index information and scale inhibitor concentration information of boiler water in a period;

[0051] Step S302, based on the index information...

Embodiment 3

[0058] like figure 1 As shown, the scale inhibition method for a boiler according to an embodiment of the present invention includes the following steps:

[0059] Step S1, extract a small amount of boiler water at the boiler dosing port in advance, collect the index information of the boiler water, and obtain the concentration of the added scale inhibitor;

[0060] In step S2, the outlet of the deaerator port of the boiler is used as the dosing port, and the scale inhibitor is added, and the scale inhibitor mainly contains pure water, sodium alginate, organic phosphate, trisodium phosphate, sodium hydroxide, and oxygen scavenger. and metal corrosion inhibitors;

[0061] Step S3, monitoring the effect of the scale inhibitor, and adjusting the scale inhibitor concentration, including the following steps;

[0062] Step S301, collecting index information and scale inhibitor concentration information of boiler water in a period;

[0063]Step S302, based on the index information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com