Pulverized coal pyrolysis system capable of removing ash through rapping

A rapping ash removal and pyrolysis technology, which is applied in the directions of dissolution, gas dust removal, and climate sustainability, can solve problems such as high-temperature and explosive gas explosions, high safety risks, and temperature rise of cyclone separators, so as to prevent heat dissipation from being insufficient. , Improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical solutions of the present invention, the content of the present invention is further described below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

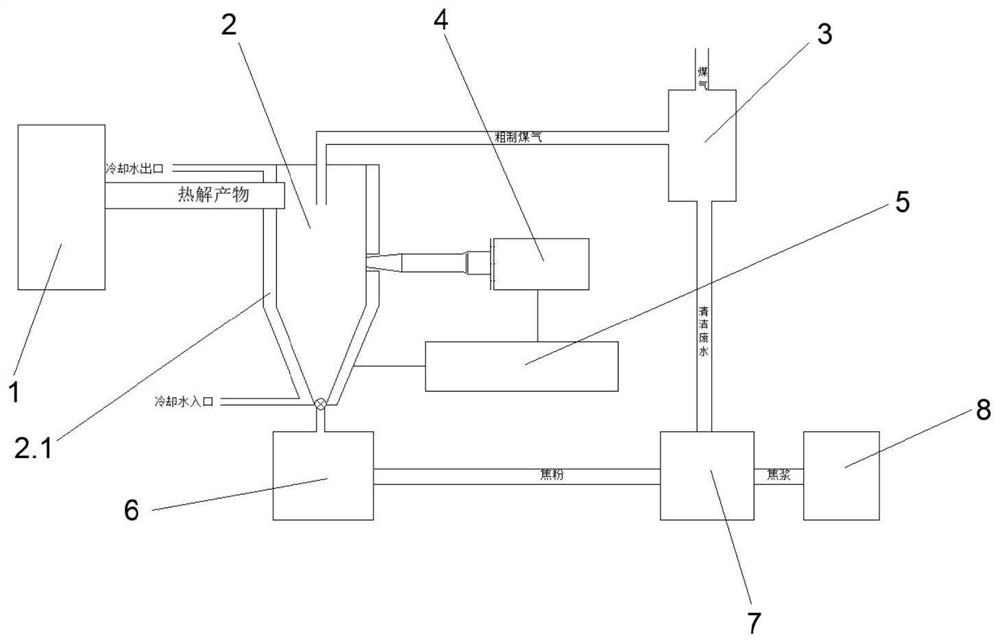

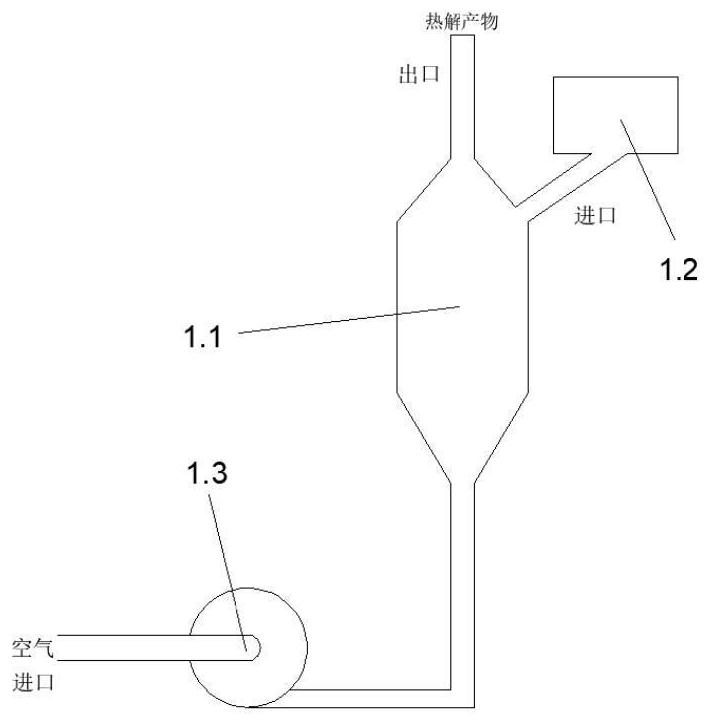

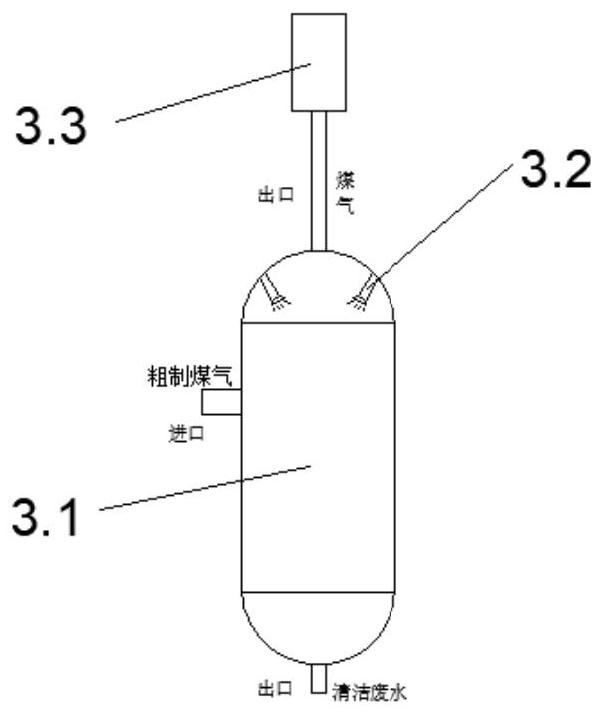

[0021] like figure 1 The shown pulverized coal pyrolysis system that can be vibrated and removed includes a pulverized coal pyrolysis unit 1, a cyclone separator 2, a coke powder pressurization conveying unit 6, a coke powder slurrying unit 7 and a gas cleaning unit 3; the The pyrolysis product outlet of the pulverized coal pyrolysis unit 1 is communicated with the top inlet of the cyclone separator 2 through a pipeline, and the gas outlet at the top of the cyclone separator 2 is communicated with the inlet of the gas cleaning unit 3 through a pipeline. The gas output pipeline is connected; the coke powder outlet at the bottom of the cyclone separator 2 is communicated with the inlet of the coke powder slurrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com