Waste heat recovery system for net part of paper machine

A technology of waste heat recovery system and wire section, which is applied in the direction of paper machine, paper making, dryer section, etc. It can solve the problems of uneven paper, heat can not be recovered in time, achieve good water removal and drying, increase diversity, and increase drying speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

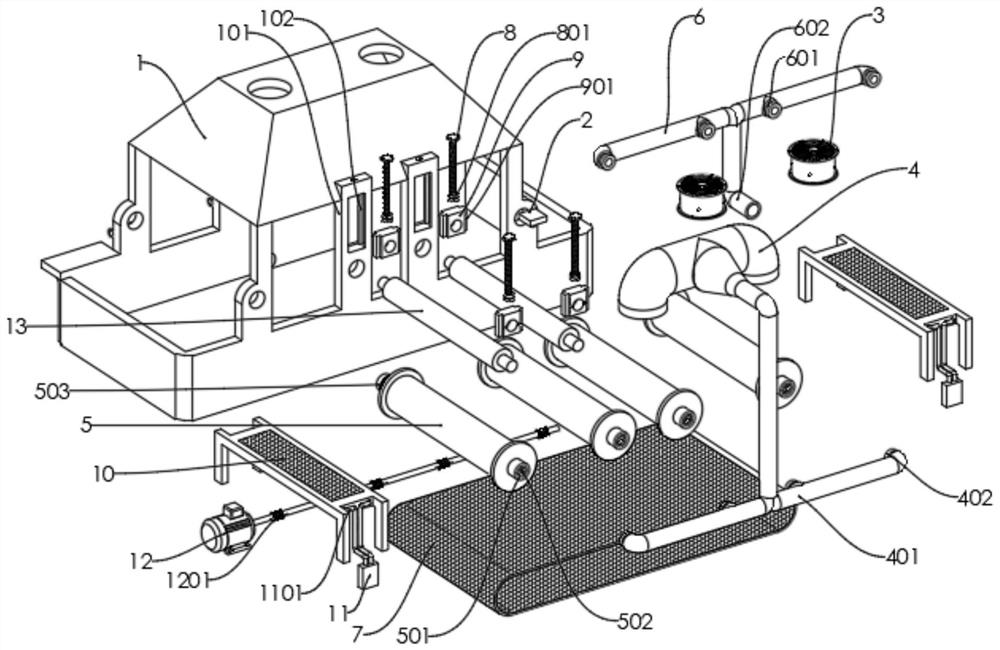

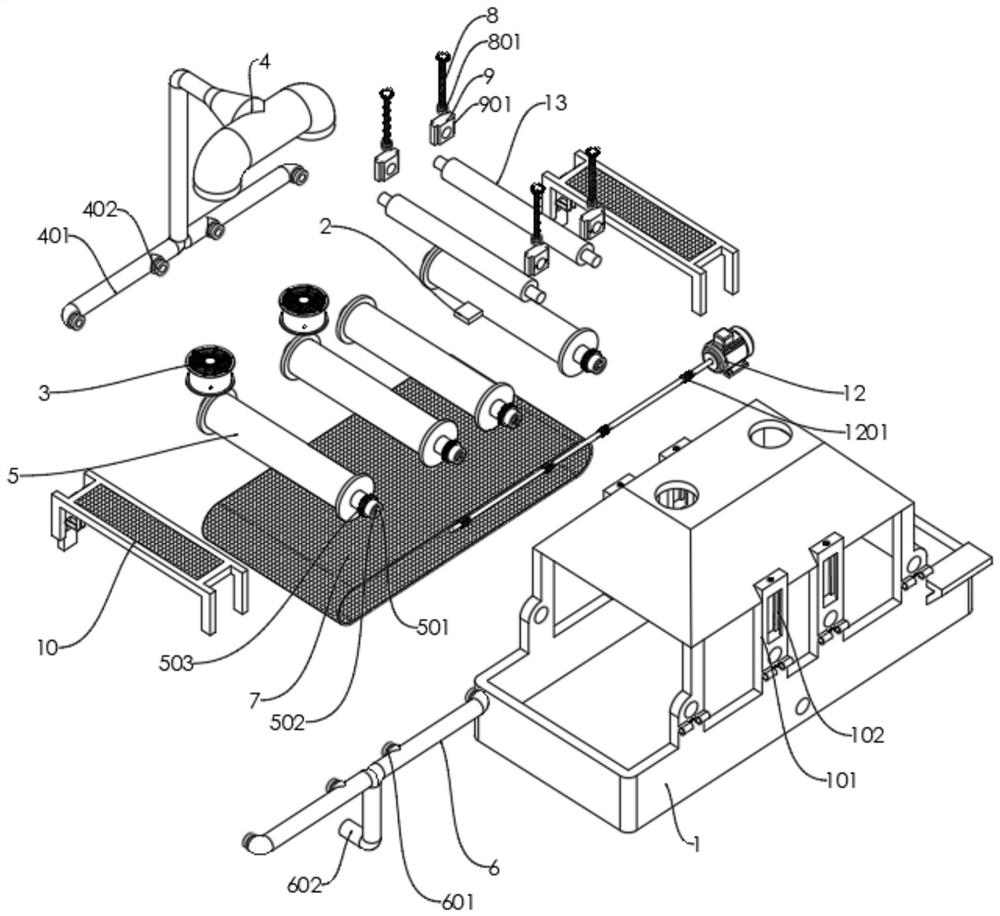

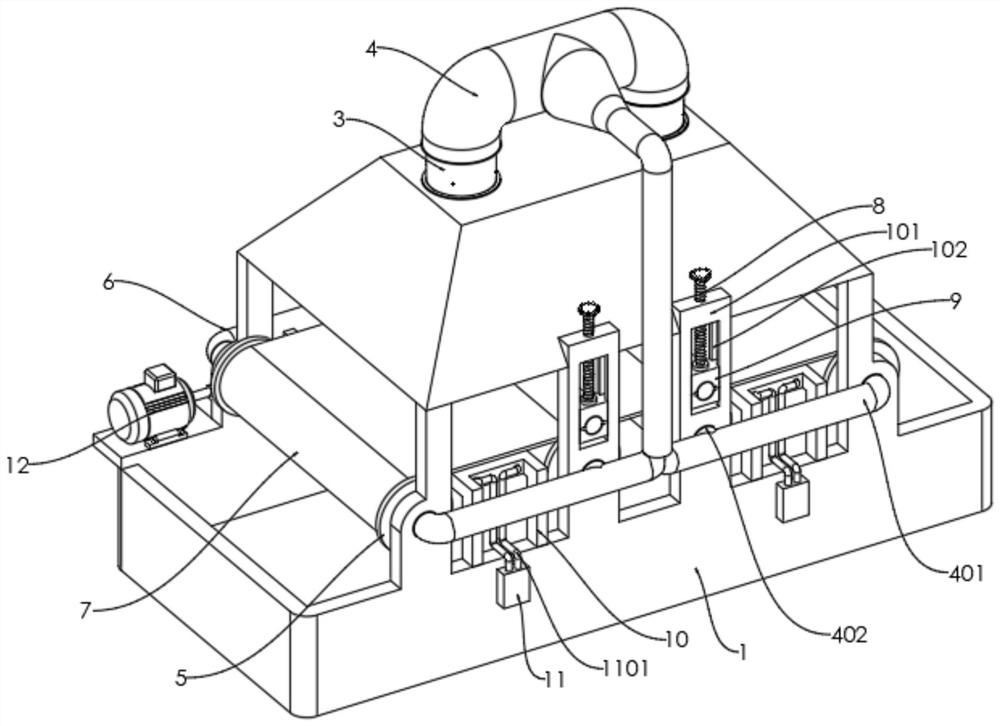

[0034] Example: please refer to Figure 1 to Figure 8 shown:

[0035] The invention provides a waste heat recovery system for the wire part of a paper machine, comprising a frame 1, the bottom of the frame 1 is a rectangular box-like structure with an open top, a trapezoidal cover is arranged on the top of the frame 1, and the top of the trapezoidal cover is installed There is an axial flow fan 3, four driving rollers 5 are rotatably connected in the middle of the frame 1, and a pressing roller 13 is arranged on the top of the two driving rollers 5 in the middle of the frame 1, and both ends of the pressing roller 13 are rotatably connected to the adjusting block 9. Among them, the outside of the drive roller 5 is provided with a mesh conveyor belt 7, the inner left and right ends of the mesh conveyor belt 7 are provided with drying brackets 10, a drive motor 12 is installed on the top of the left rear side of the frame 1, and the rear end of the drive roller 5 is connected wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap