Double-effect steam turbine power generation system

A power generation system and steam turbine technology, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of increased system energy consumption and large heat energy loss, and achieve the effects of reducing heat energy loss, reducing heat energy loss, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

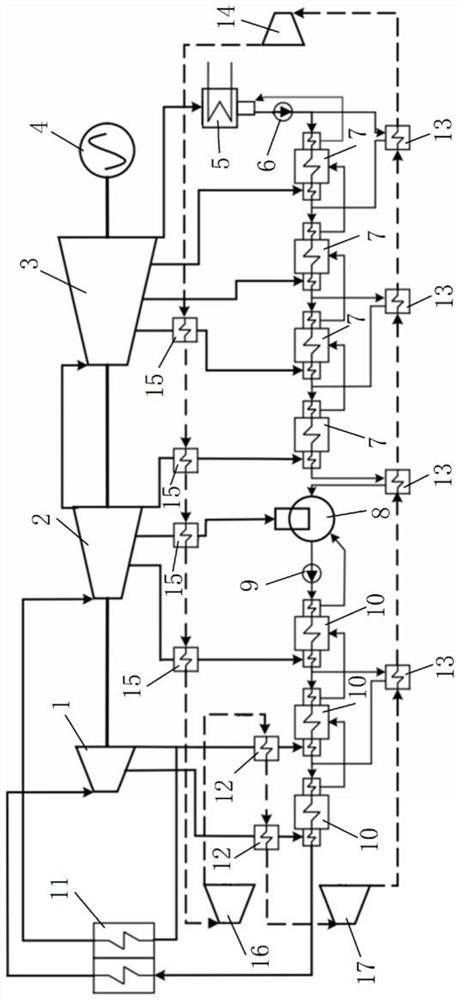

[0032] like figure 1 A dual-effect steam turbine power generation system provided in this embodiment is shown, including: a first circulation pipeline and a second circulation pipeline that are coupled to each other for heat exchange.

[0033] The first circulation pipeline includes a boiler, a steam turbine unit, a condenser 5, a condensate water pump, a multi-stage low-pressure heater 7, a deaerator 8, a feed water pump 9 and a multi-stage high-pressure heater 10 that are circulated and communicated as an evaporator 11. . The second circulation pipeline includes a high-pressure turbine as the first turbine 16, a reheater 12, a low-pressure turbine as the second turbine 17, a condenser body 13, a compressor 14, and a heater in cyclic communication. device body 15. At least one stage low pressure heater 7 and at least one stage high pressure heater 10 are arranged in parallel with the liquid side of the condenser body 13; between the low pressure heater 7 and the steam turbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com