Roadside coal body impact risk assessment method based on borehole stress distribution

A stress distribution and coal body technology, applied in earthwork drilling, force/torque/work measuring instruments, instruments, etc., can solve the problems of danger, time-consuming and labor-intensive drilling cuttings holes, failure to impact risk assessment, etc., and achieve the assessment results Effects that are quantifiable, operable, and physically meaningful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

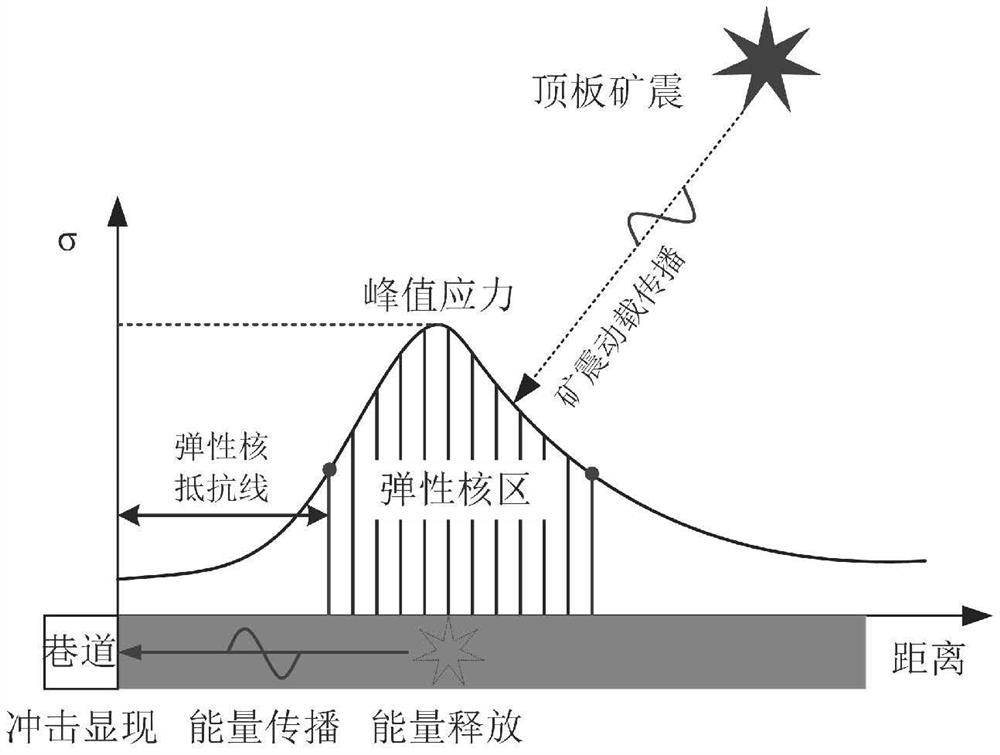

[0035] The present invention utilizes the high stress impact model of the roadway gang coal body under the mine vibration load condition, that is, the pure static load condition is equivalent to the dynamic load of 0MPa:

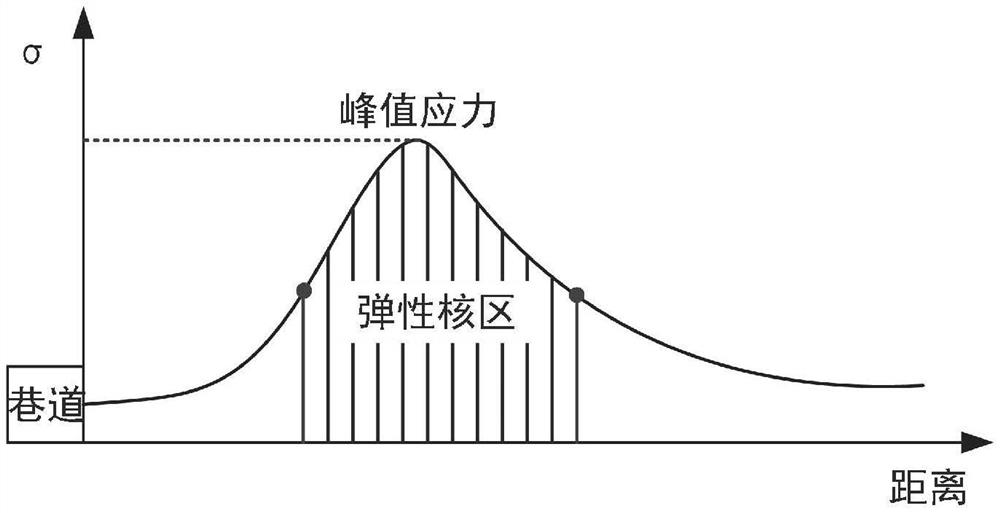

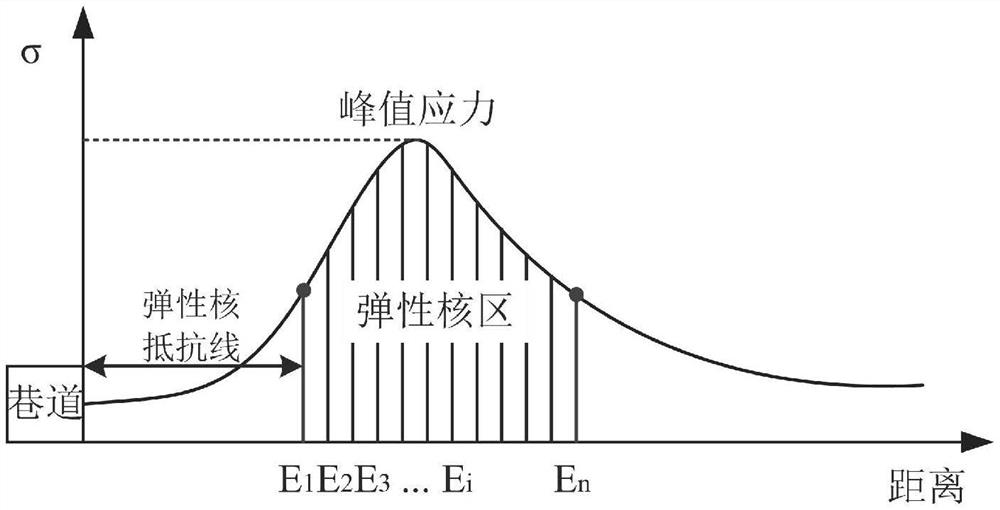

[0036] The stress distribution state of the roadway coal body is as follows: figure 1Shown: From the surface of the coal body in the roadway to the deep part of the coal body, there are the stress-reduced area, the stress-increased area and the original rock stress area. Among them, the greatest threat to the roadway is the stress increase area, especially the area with obvious stress increase, which is called the elastic core area here. Under the superposition of pure static load or surrounding dynamic load, when the stress in the elastic core zone of the coal body in the roadway reaches the level of the coal body failure stress, part of the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com