Apparatus and method for producing an improved laser beam

A technology of laser beams and optical components, used in lasers, laser welding equipment, laser parts and other directions, can solve the problems of small beam area, non-uniform power distribution, insufficient processing rate, etc., to improve surface quality, improve power distribution, The effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

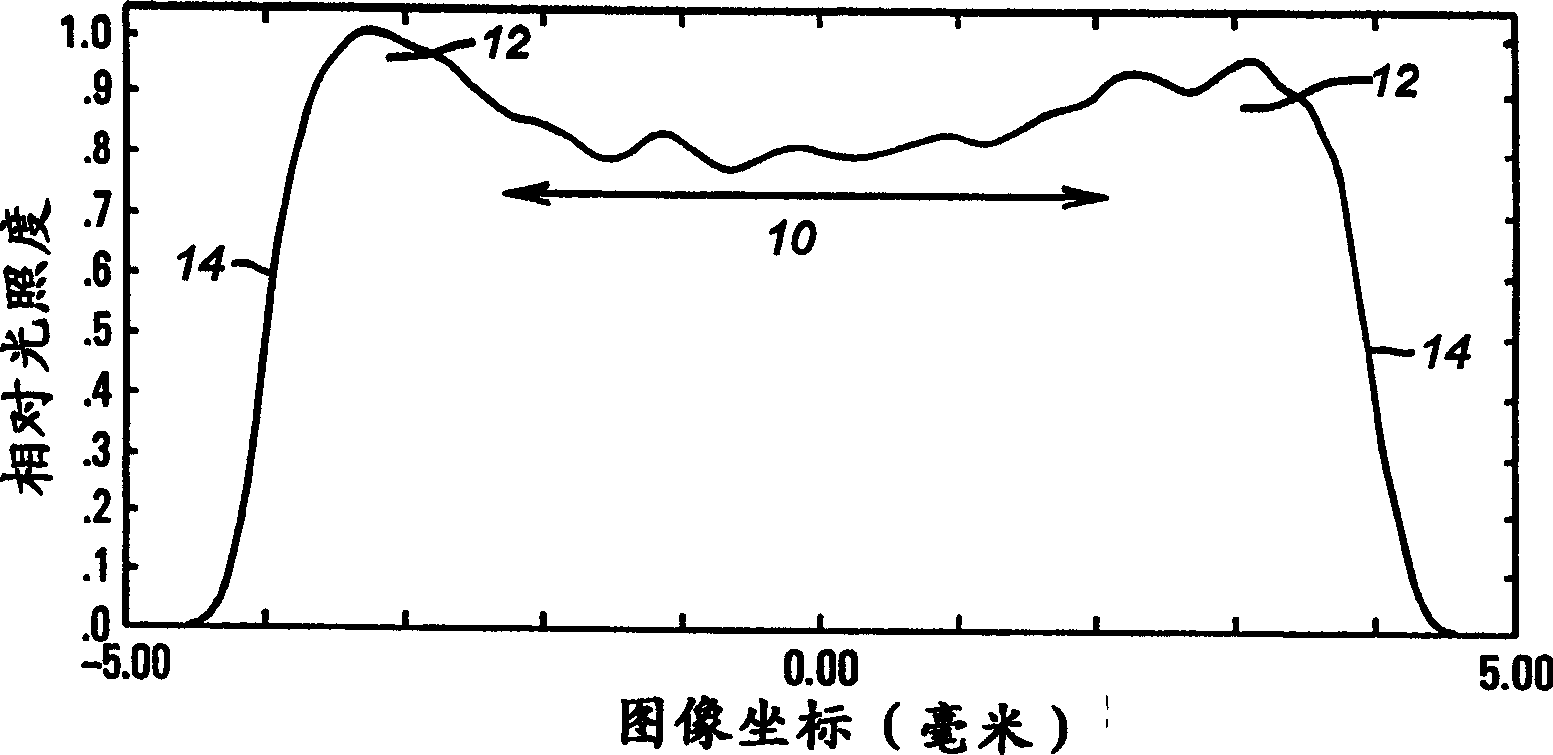

[0030] In a preferred embodiment, as attached Figure 2C As shown, the laser beam of the present invention has a rectangular cross-section 20 with a width dimension 22 and a length dimension 24 . In preferred embodiments, the width dimension of said bundle is at least 8 times the length dimension of said bundle. The ratio of the width dimension to the length dimension measured at the position of half the maximum intensity is hereinafter referred to as the "aspect ratio".

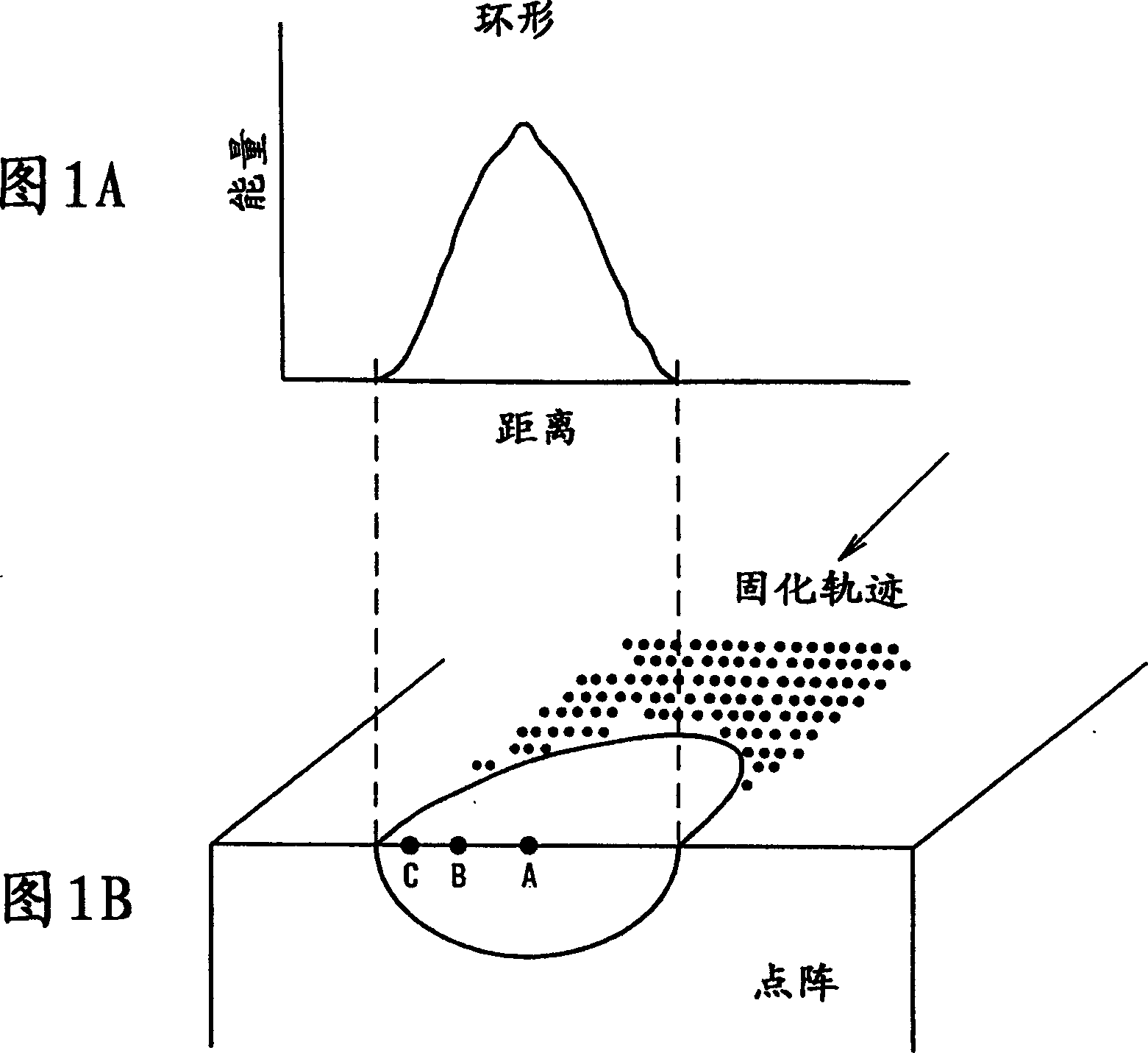

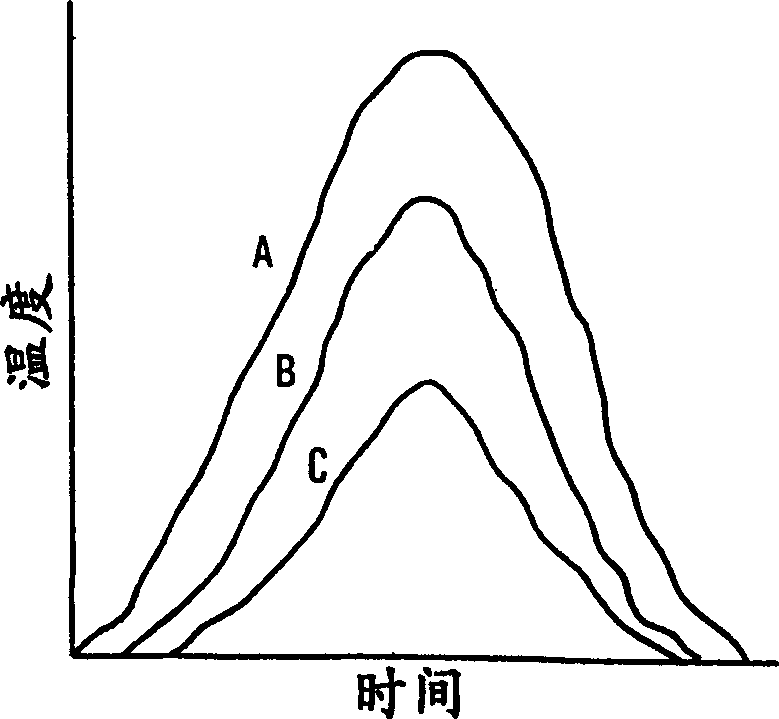

[0031] as attached Figure 2A As shown in , the laser beam of the present invention includes such a power distribution on the width dimension, that is, the power distribution is substantially constant in the central region 10, increases in the outer region 12, and substantially steps in the end regions 14 of its width dimension. function way down. The ratio of the intensity or magnitude of the power distribution in the outer zone to the intensity or magnitude in the central zone is greater than or equal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com