Harmless treatment method for chlorinated organic compounds in soil

A technology for the harmless treatment of chlorinated organic compounds, which is applied in the field of soil remediation and the harmless treatment of chlorinated organic compounds in soil. The effects of high chlorine efficiency, increased degradation rate, and improved treatment degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

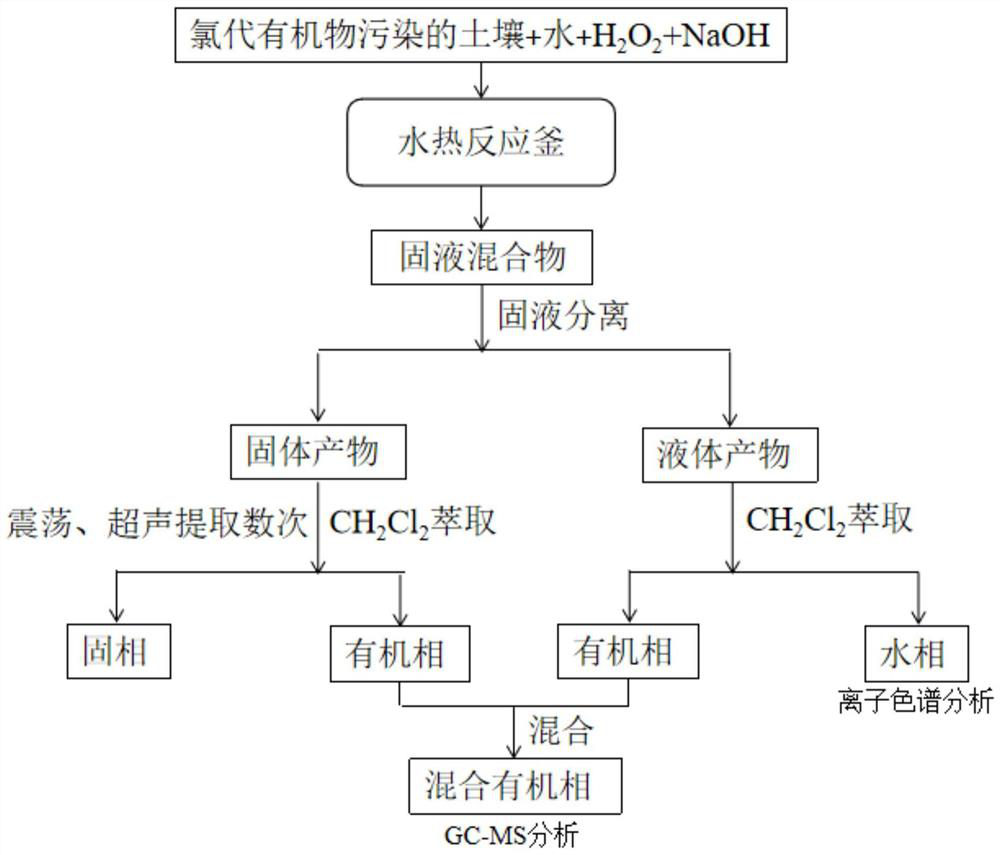

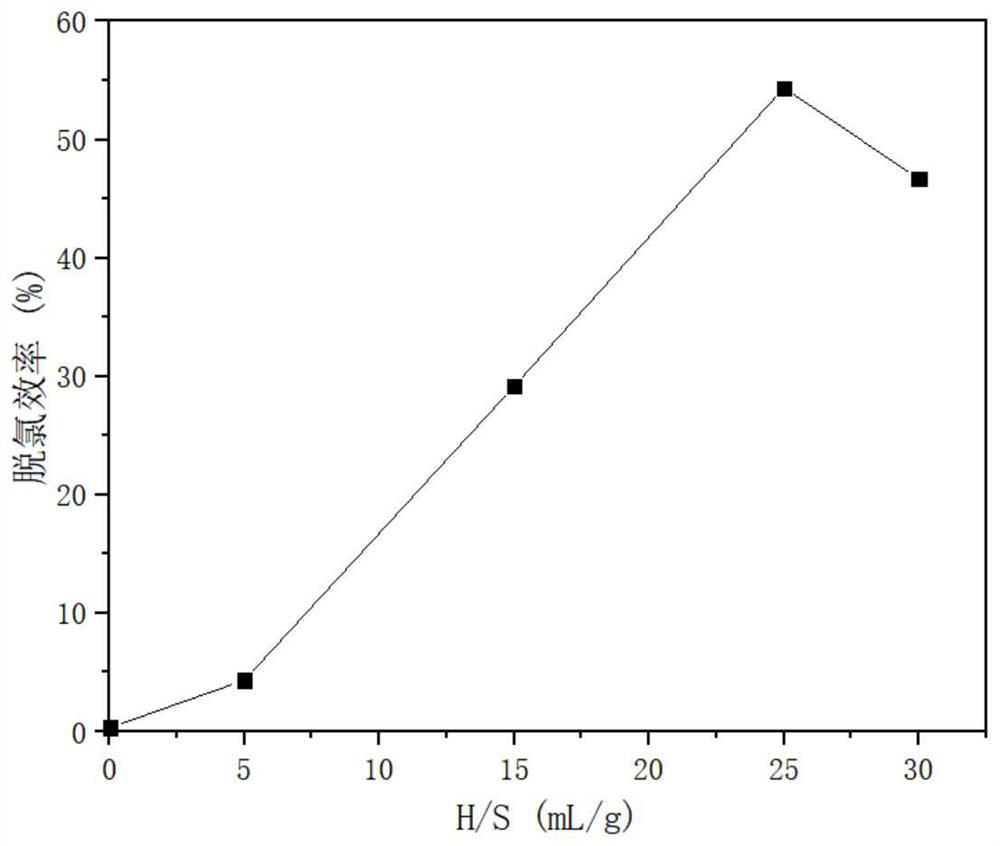

[0036] in accordance with figure 1 As shown in the flowchart, take 1g of triclosan-contaminated soil and add different volumes (5mL, 10mL, 15mL, 20mL, 25mL, 30mL) of 30% hydrogen peroxide (the volume of hydrogen peroxide added at the beginning is the same as that of the contaminated soil The mass ratio is the initial liquid-solid ratio (mL / g), 50mg of sodium hydroxide and 50mL of ultrapure water are placed in a reaction kettle, put into an electric blast drying oven with a set temperature of 180°C, and the reaction time is 120min Finished, let cool.

[0037] Open the reactor, separate all the samples in the reactor from solid to liquid, and add an equal volume of extractant CH to the liquid part. 2 Cl 2The organic matter was extracted, and the aqueous phase and the first organic phase after extraction and separation were collected respectively, and the aqueous phase was quantified to 100 mL. Add the extractant CH to the solid part 2 Cl 2 The organic matter was extracted b...

Embodiment 2

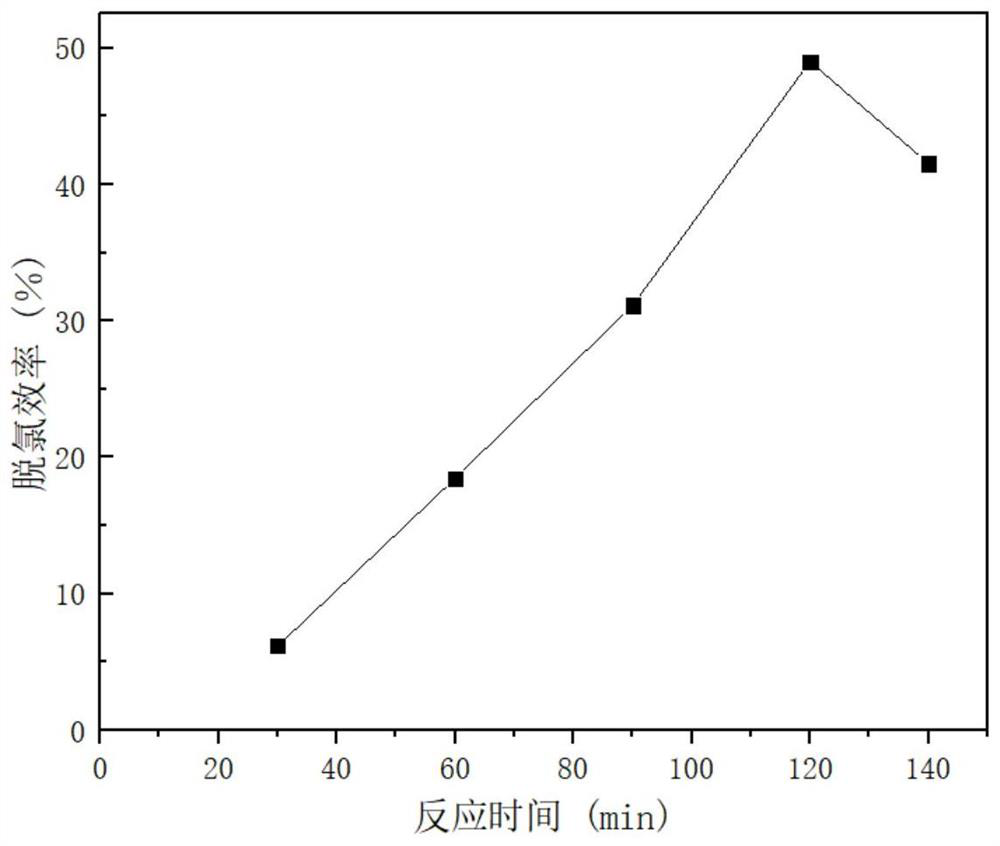

[0042] in accordance with figure 1 In the flow chart given, take 1g of triclosan-contaminated soil and add 25mL of 30% hydrogen peroxide, 50mg of sodium hydroxide and 50mL of ultrapure water into the reactor, and put it into ℃ electric blast drying oven, the reaction time is 30min, 60min, 90min, 120min, 140min, after the timing is over, cool down.

[0043] Open the reactor, separate all the samples in the reactor from solid to liquid, and add an equal volume of extractant CH to the liquid part. 2 Cl 2 The organic matter was extracted, and the aqueous phase and the first organic phase after extraction and separation were collected respectively, and the aqueous phase was quantified to 100 mL. Add the extractant CH to the solid part 2 Cl 2 The organic matter was extracted by a shaker and ultrasound, and the above operation was repeated three times to obtain a solid phase and a second organic phase, and the above two organic phases were mixed. The organic phase was filtered a...

Embodiment 3

[0046] in accordance with figure 1 In the flow chart given, take 1g of triclosan-contaminated soil and add 25mL of 30% hydrogen peroxide, 50mg of sodium hydroxide and 50mL of ultrapure water into the reactor, and put it into ℃ electric blast drying oven, time 120min, and cool down. Open the reactor, separate all the samples in the reactor from solid to liquid, and add an equal volume of extractant CH to the liquid part. 2 Cl 2 The organic matter was extracted, and the aqueous phase and the first organic phase after extraction and separation were collected respectively, and the aqueous phase was quantified to 100 mL. Add the extractant CH to the solid part 2 Cl 2 The organic matter was extracted by a shaker and ultrasound, and the above operation was repeated three times to obtain a solid phase and a second organic phase, and the above two organic phases were mixed. The organic phase was filtered and analyzed by GC-MS. After the water phase product has been fixed to volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com