Red mud cracking treatment device

A technology of cracking treatment and pretreatment device, applied in the direction of heat treatment, combined device, chemical/physical process, etc., can solve the problems of increased production cost, loss of practicability, inability to extract, etc., to improve the degree of harmlessness and improve melting combustion. Sufficient degree, the effect of improving the degree of complete melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

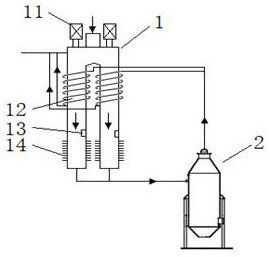

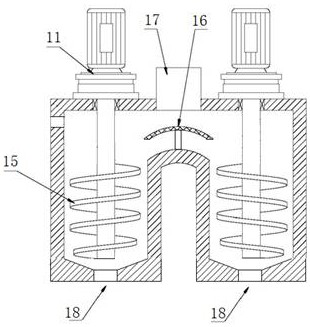

[0038]This embodiment provides a red mud cracking treatment device, such as figure 1 with 2 shown, including:

[0039] Feed pretreatment device 1, the lower part of the furnace body of feed pretreatment device 1 is formed into more than two cylinders, the inlet 17 for inputting red mud is located at the center of the top of the furnace body, and the outlet 18 for outputting materials is respectively located at At the center of the bottom of the column, the feed pretreatment device 1 is used to heat the red mud to make it dry, and can evaporate and crack the components that are easy to evaporate and crack, and the obtained materials are output from the outlet 18 of the feed pretreatment device 1 to the high temperature plasma melting device 2; and

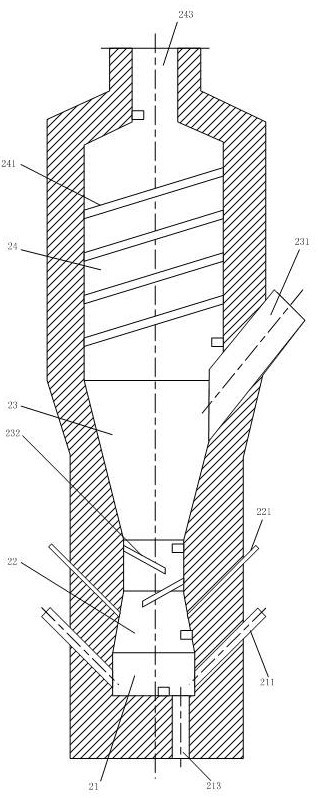

[0040] The high-temperature plasma melting device 2 is used to melt the input materials with a high-temperature plasma torch and transform them into vitreous waste slag and CO 2 , CO and H 2 of synthetic gas.

[0041] Preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com