Oil sludge cracking treatment method

A technology for cracking treatment and sludge, applied in chemical instruments and methods, petroleum industry, transportation and packaging, etc., to achieve the effect of improving the degree of harmless treatment and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

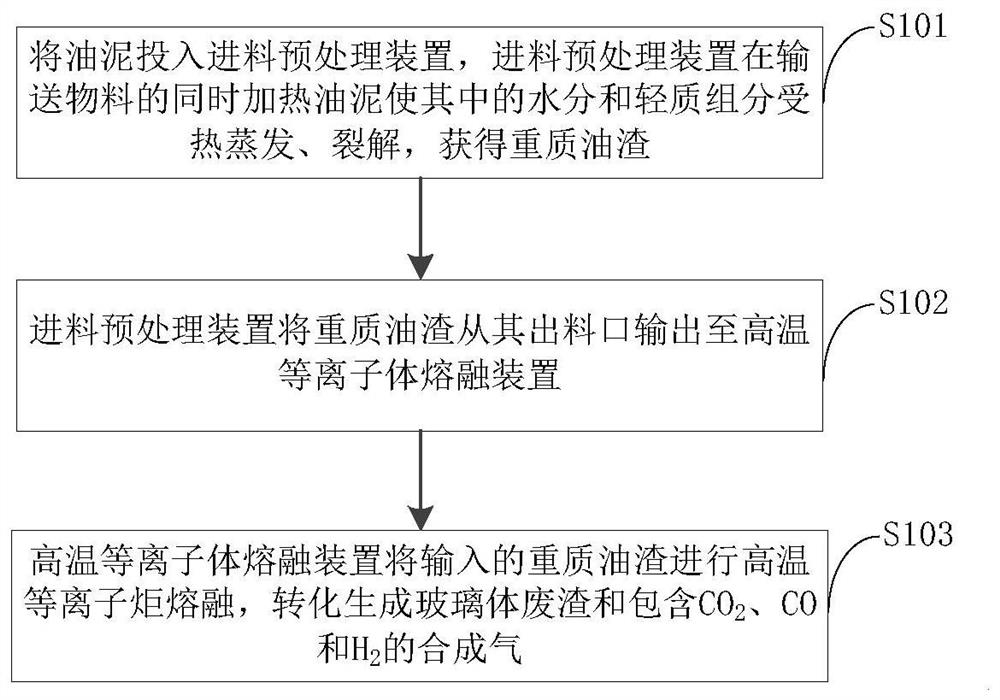

[0035] This embodiment provides a kind of sludge cracking treatment method, such as figure 2 shown, including the following steps:

[0036] S101. Put the oil sludge into the feed pretreatment device, and the feed pretreatment device heats the oil sludge while conveying the material to evaporate and crack the moisture and light components in the sludge to obtain heavy oil residue;

[0037] S102. The feed pretreatment device outputs the heavy oil residue from its outlet to the high temperature plasma melting device;

[0038] S103. The high-temperature plasma melting device melts the input heavy oil slag with a high-temperature plasma torch, and transforms it into vitreous waste slag containing CO 2 , CO and H 2 of synthetic gas.

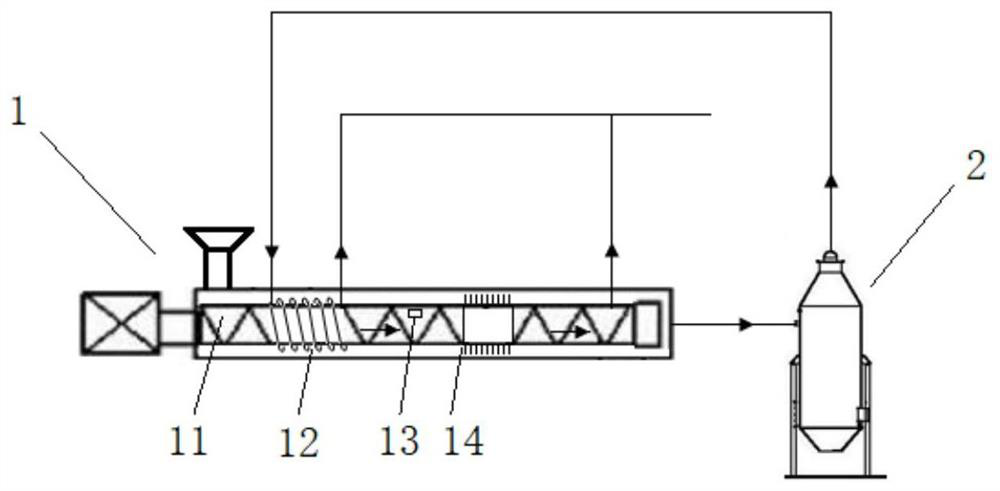

[0039] Among them, the oil sludge cracking treatment device, such as figure 1 shown, including:

[0040] The feed pretreatment device 1 is used to heat the oil sludge to evaporate and crack the moisture and light components in it to obtain heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com