Pipe coupling

A technology of pipe joints and joints, applied in the field of pipe joints, can solve the problems of air leakage and incomplete sealing, and achieve the effects of improving performance, improving air tightness and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

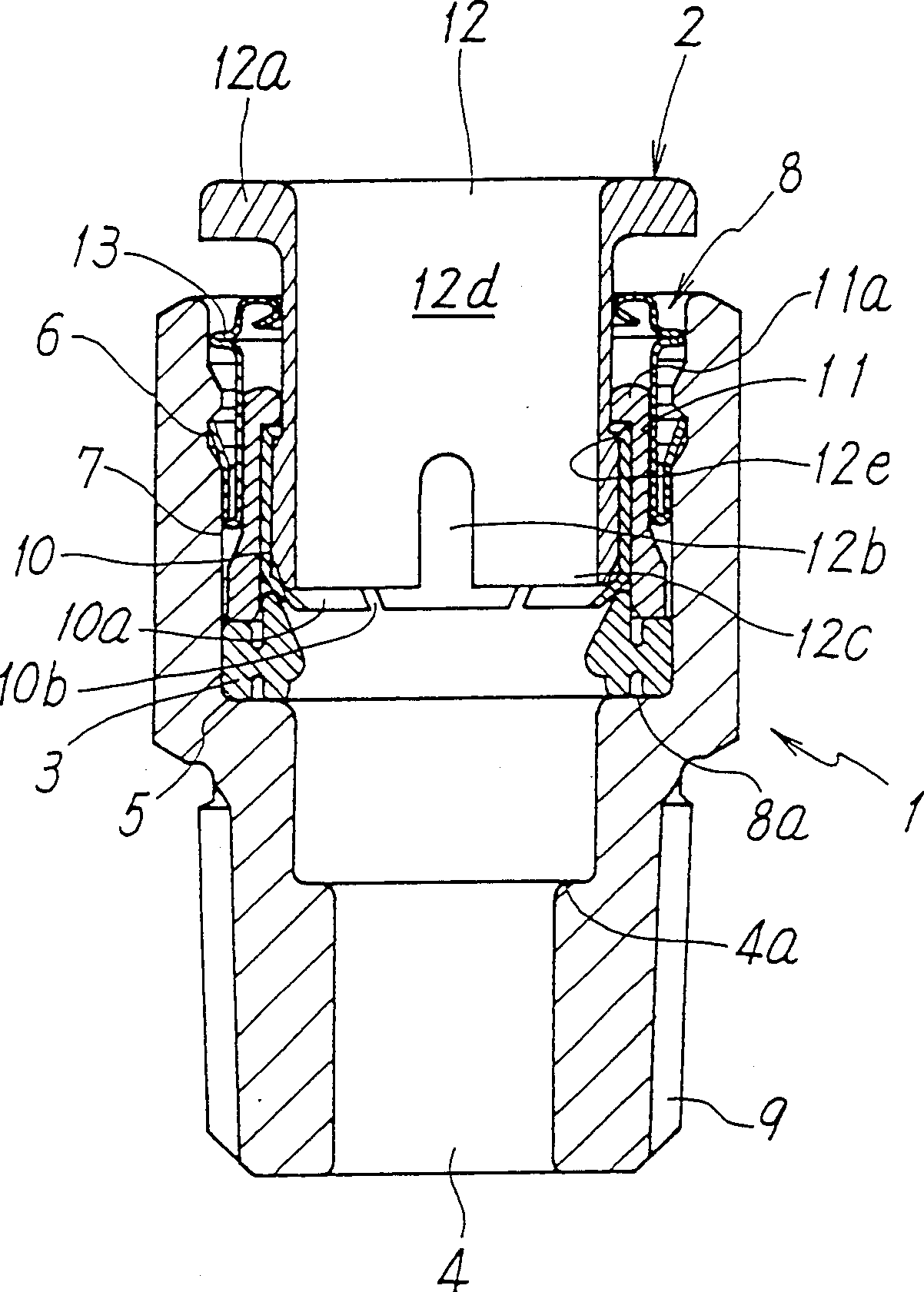

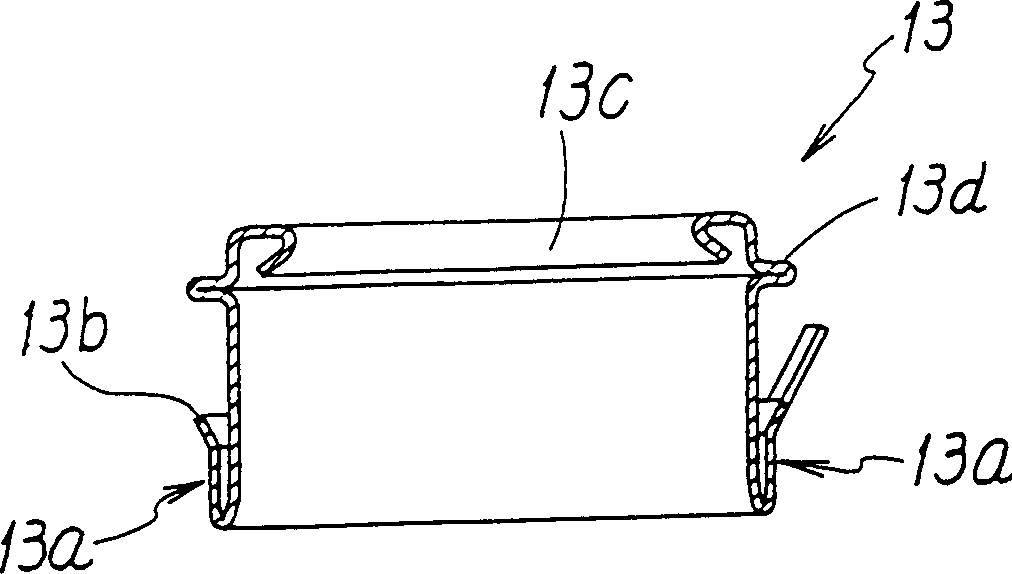

[0018] figure 1 An example of the pipe joint of the present invention is shown. The pipe joint of this embodiment has a joint main body 1 forming the outer peripheral portion of the pipe joint, a pipe holding mechanism 2 for holding the pipe end assembled in the joint main body 1, and a pipe holding mechanism 2 accommodated in the joint. The elastic sealing member 3 inside the body 1 .

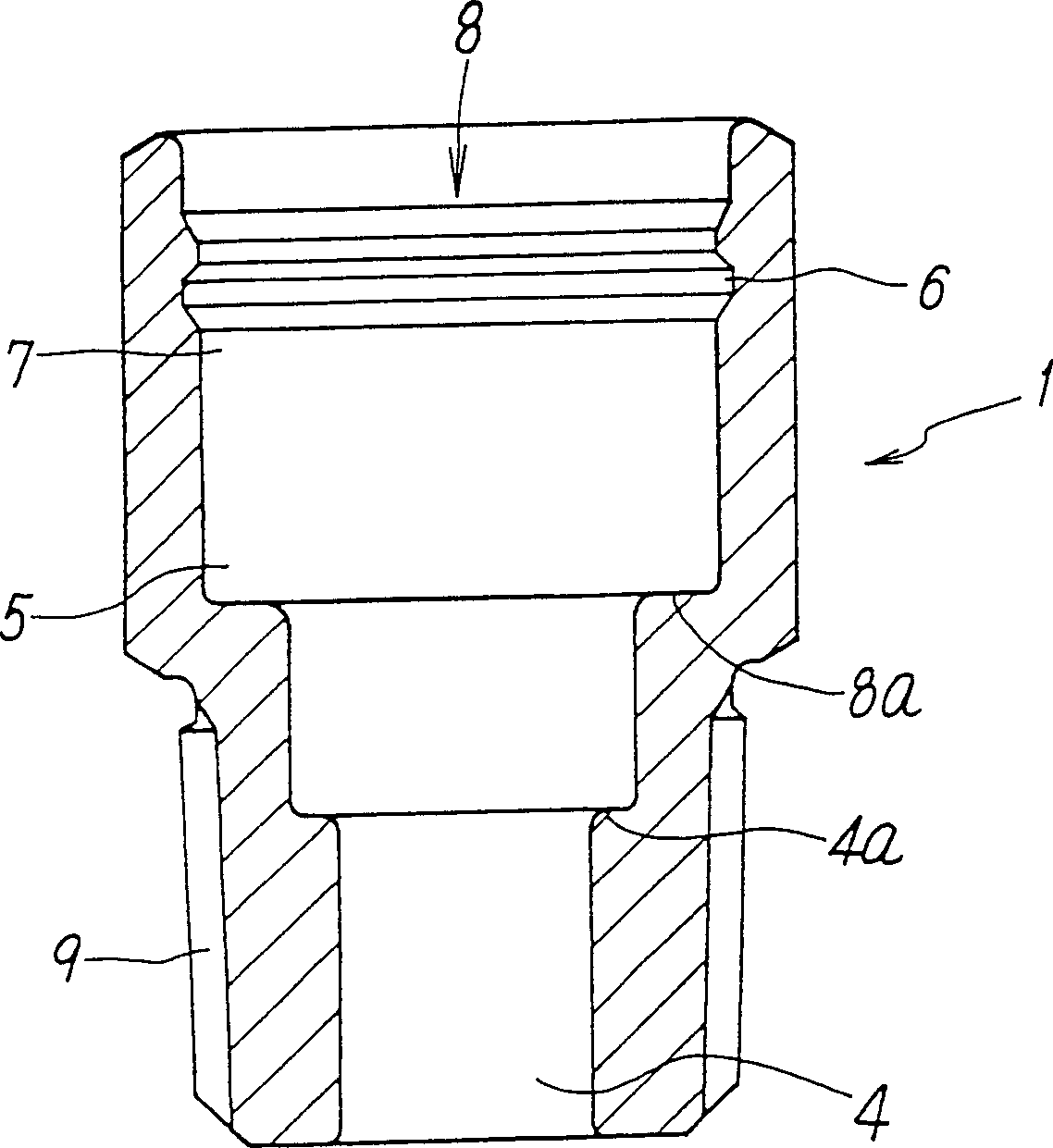

[0019] The above-mentioned joint body 1 is formed by cold forging of iron-based metal materials. figure 2 It can be seen that a fluid flow path 4 is provided through the joint body 1 in the axial direction, and the fluid flow path 4 allows fluid to flow between the pipe and the hydraulic pressure machine. On one end side of the fluid flow path 4 of the joint body 1, an enlarged diameter The recessed portion 8 has the receiving portion 5 for the seal member on the inner side and the receiving portion 7 for the tube holding mechanism on the mouth side, and has the engagement groove 6 for the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap