Plastic thermal insulation cushion and its working method

A heat-insulating mat and plastic technology, applied in the field of plastic products and its processing, can solve the problems of eliminating fire hazards, non-fire prevention, and unsolvable problems, and achieve the effect of eliminating fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

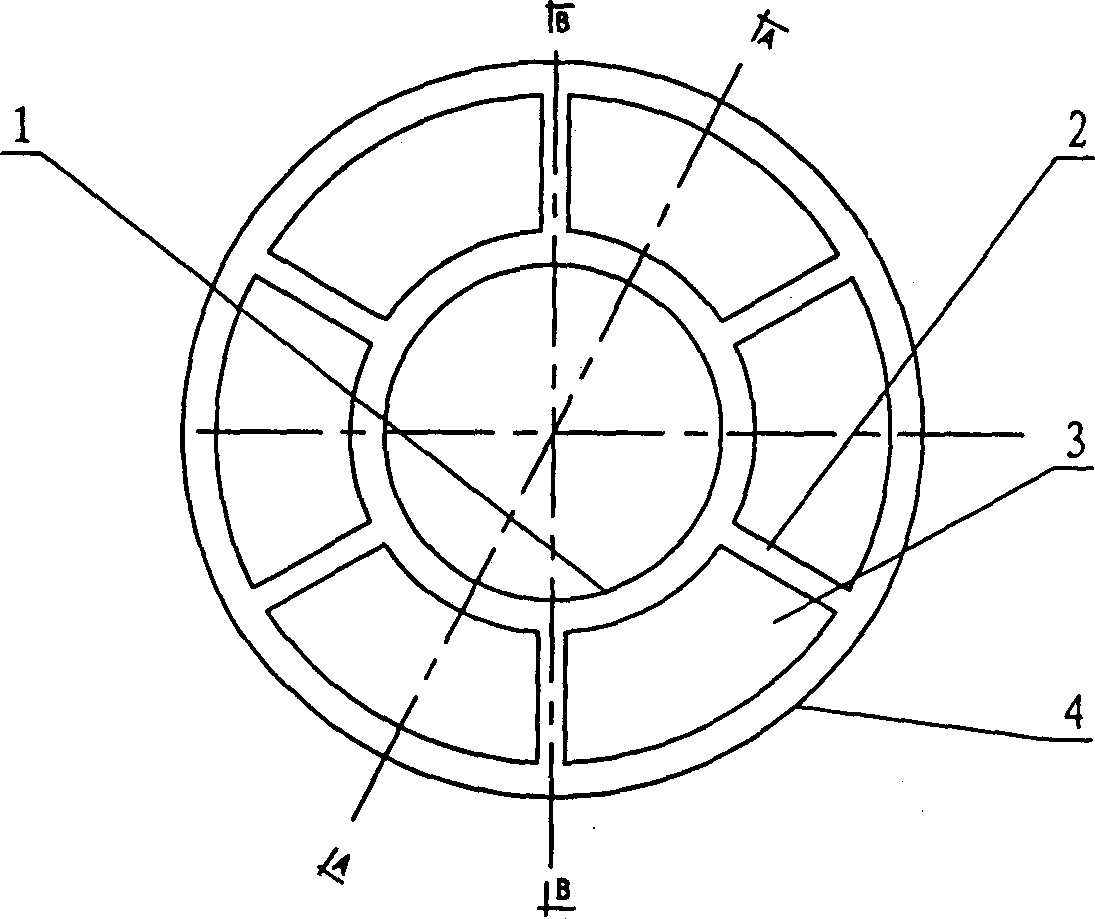

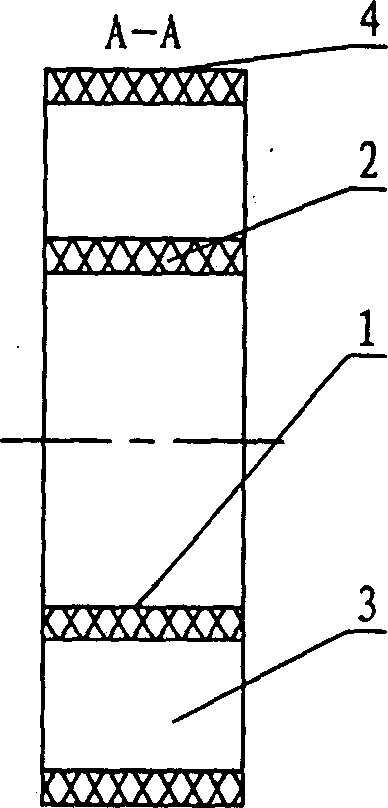

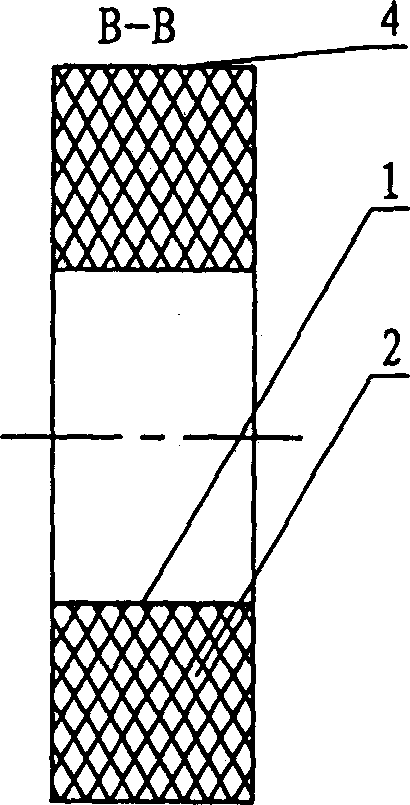

[0025] according to Picture 1-1 3. Describe in detail the specific structure and working conditions of the present invention. The plastic heat insulating pad is an integral gasket with compartments, including a heat insulating surface 1 and a supporting surface 4 , and the heat insulating surface 1 is integrated with the supporting surface 4 through a connecting body 2 with compartments 3 . It can be made into an I-type structure according to actual needs (such as Figure 1-3 shown) or type II structure (such as Figure 4-5 shown). The plastic insulation pad is made of flame-retardant hard plastic, such as hard polyvinyl chloride (PVC-U) and other materials. After mixing, it is extruded by the plastic extruder 5, and is shaped and cooled by a specific mold to become a spacer. Overall padding. This embodiment only describes a specific mold used for processing the I-type structural plastic insulation pad. Used plastics extruder 5 selects commercially available conical twin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com