Fluidized biomembrane carrier and its making method

A biofilm carrier and fluidization technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of time-consuming installation, difficult reinstallation, and high cost of immobilized biofilm carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the structure and operation of the present invention will be described with reference to the accompanying drawings.

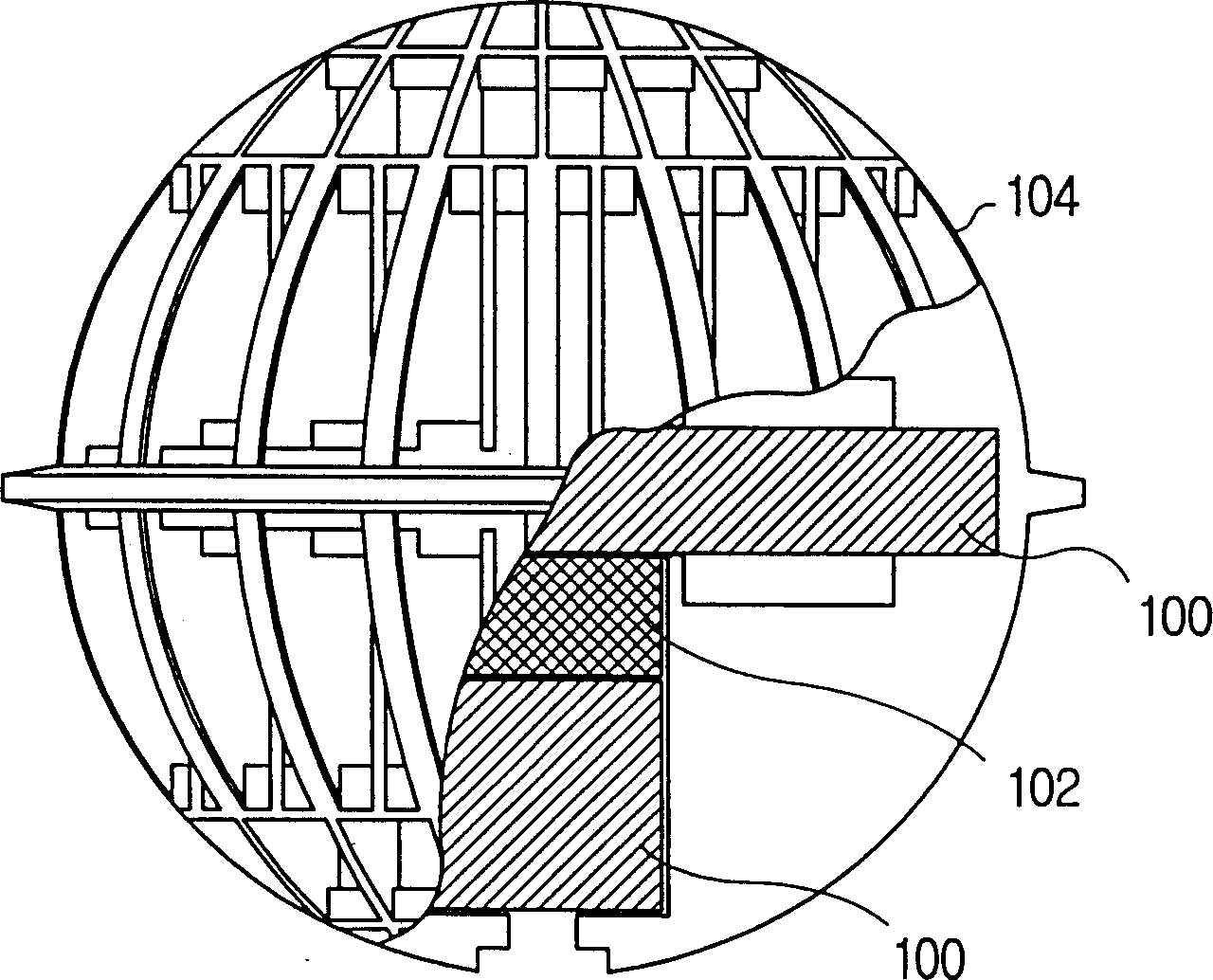

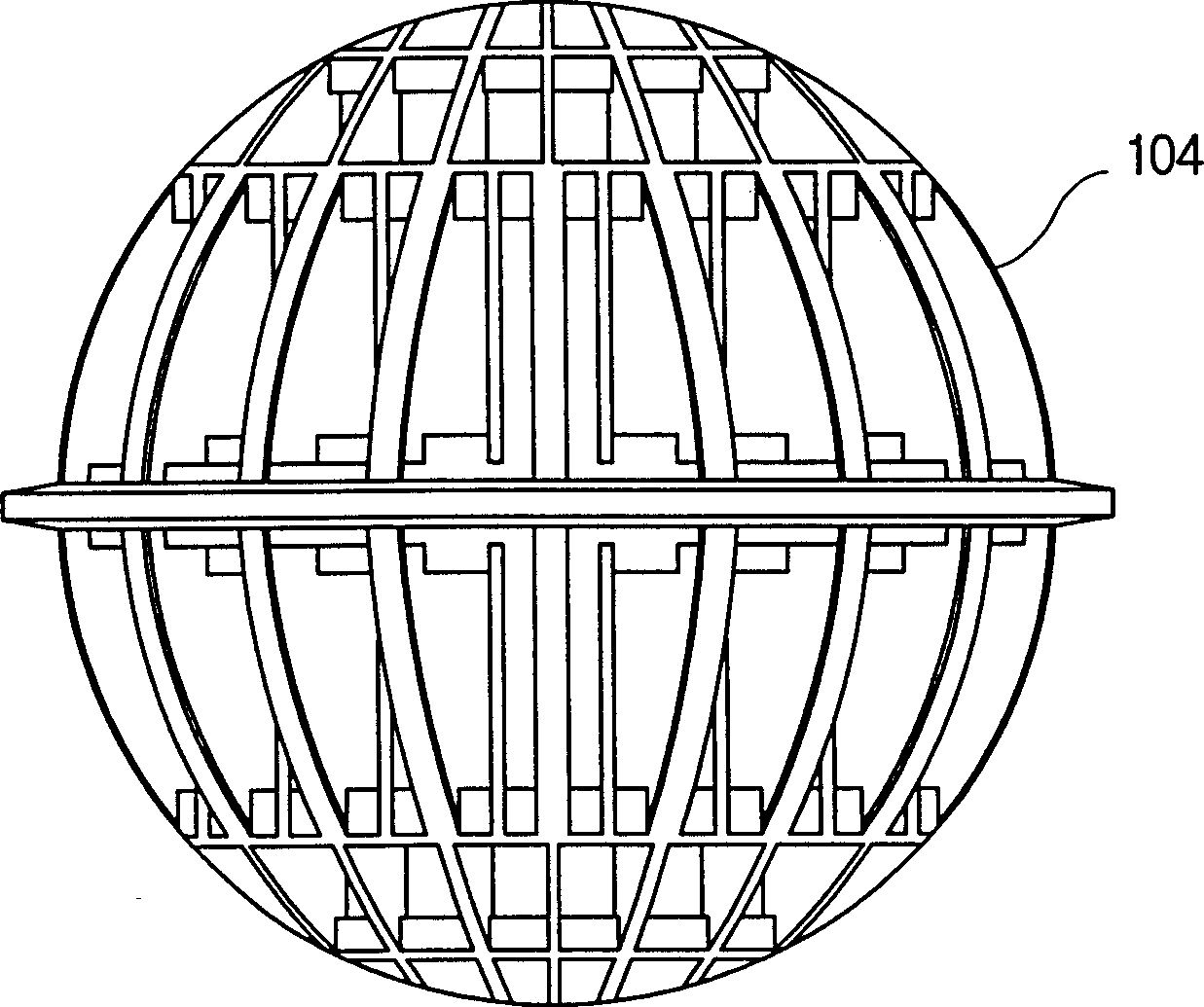

[0015] Figure 2A is a partial sectional view of a fluidized biofilm carrier according to the present invention, Figure 2B is its front view, Figure 2C is its top view.

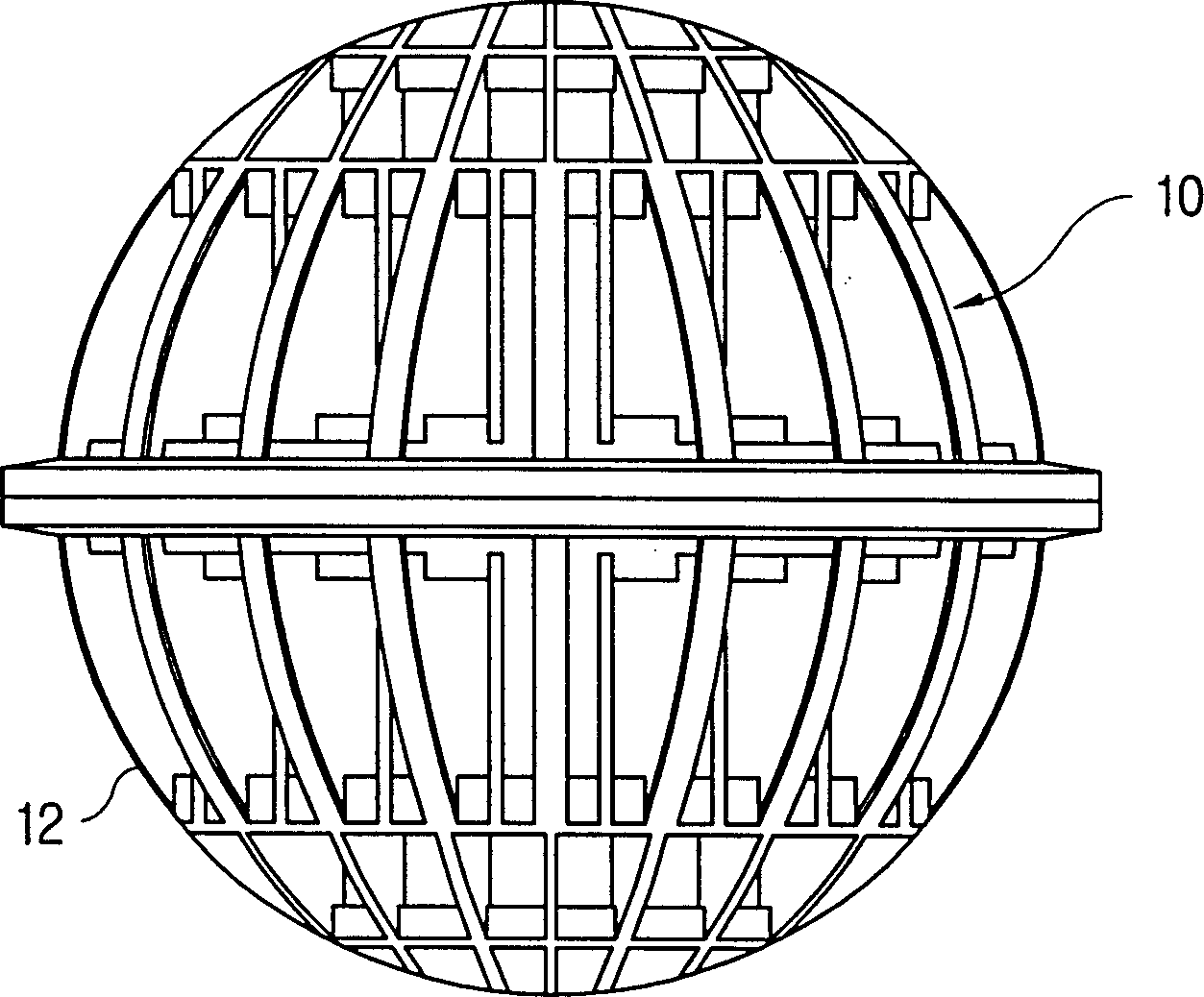

[0016] The fluidized biofilm carrier according to the present invention includes a sponge-like microorganism attachment material 100 on which microorganisms attach and multiply, a specific gravity adjustment material 102 for adjusting specific gravity, and a spherical container 104 made of synthetic resin. The spherical container 104 is formed by hot-melting the two net-shaped hemispherical parts of the container, through which water flow and air bubbles can infiltrate smoothly and evenly from the outside.

[0017] The fluidized biofilm carrier of the present invention is produced by the following method.

[0018] First, the spongy microorganism attachment material 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com