Embedded simulating test unit and process of underwell tool stress

A technology of simulation testing and downhole tools, which is applied in the field of embedded simulation testing devices, can solve the problems of large testing errors, low testing efficiency, easy damage, etc., and achieve the goal of improving testing accuracy, testing data authenticity and reliability, and overcoming testing errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

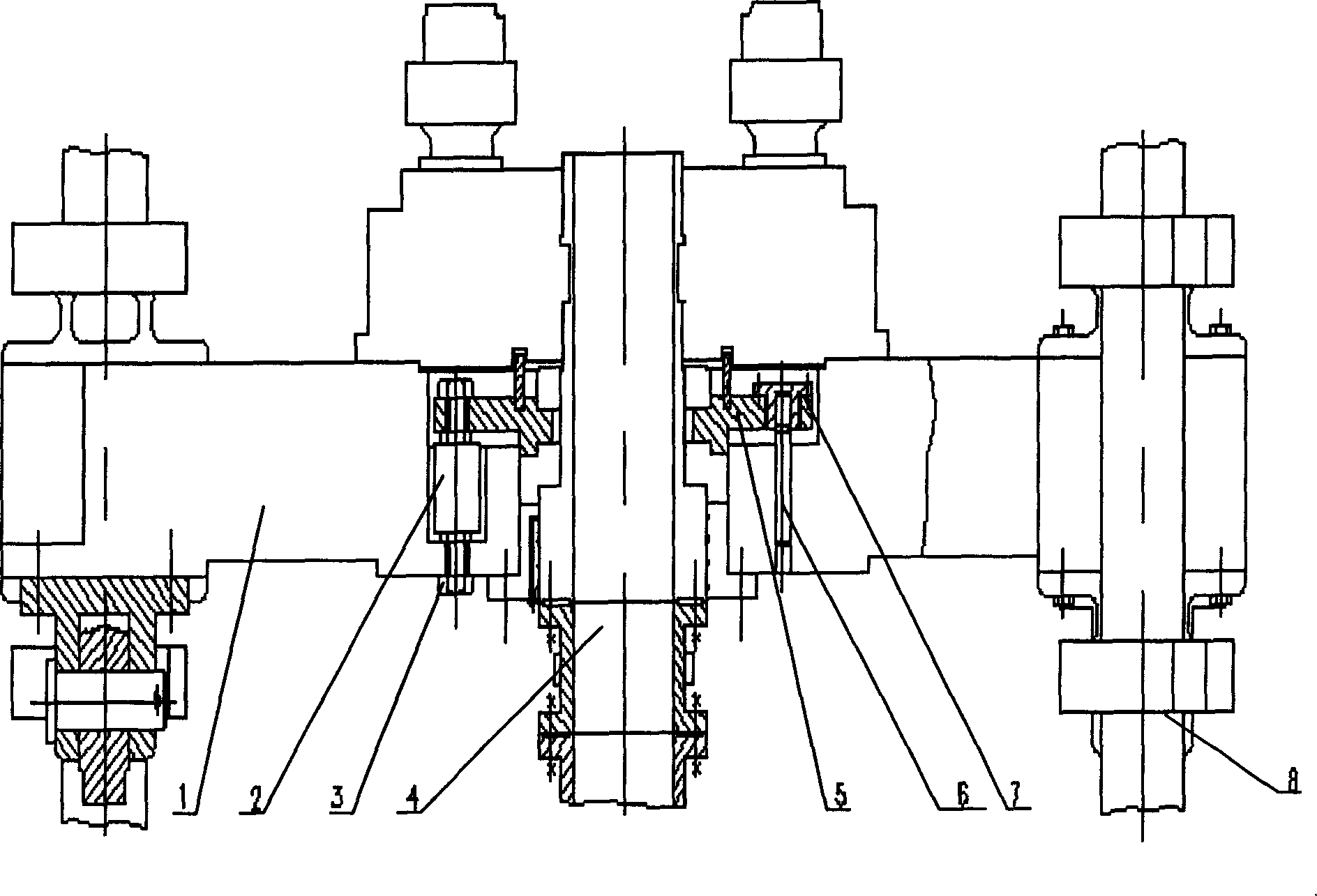

[0012] The test device and process applicable to the tension pressure of downhole tools use three embedded tension pressure sensors and a specific structure to realize the online detection of the tension pressure of downhole tools. The process is as follows: figure 1 As shown, inside the traveling beam 1, three axial tension and compression sensors 2 are evenly installed on the outside of the hollow structure, one end of each sensor is installed on the traveling beam with a fixing bolt 3, and the other end is installed on a force-bearing circle. On disc 5, in addition to installing 3 sensors on the stressed disc, 3 guide holes are evenly distributed, and 3 guide rods 6 pass through the 3 guide holes respectively, and guide rod bushings are installed between the guide rods and the guide holes 7. There is a sliding fit between the guide rod and the bushing, and one end of the guide rod is fixed to the traveling beam. When the traveling beam moves upward along the guide column 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com